Bridge wing structure for ultra-large ore carrier

A kind of ore ship, ultra-large technology, applied in ship components, ship construction, ships, etc., can solve problems such as poor effect and great difficulty, and achieve the effects of improved rigidity and support effect, safety assurance, traffic and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The embodiments are not intended to limit the scope of protection of the invention. Obviously, those skilled in the art can obtain other embodiments without having to pay creative work. Belong to the protection scope of the present invention.

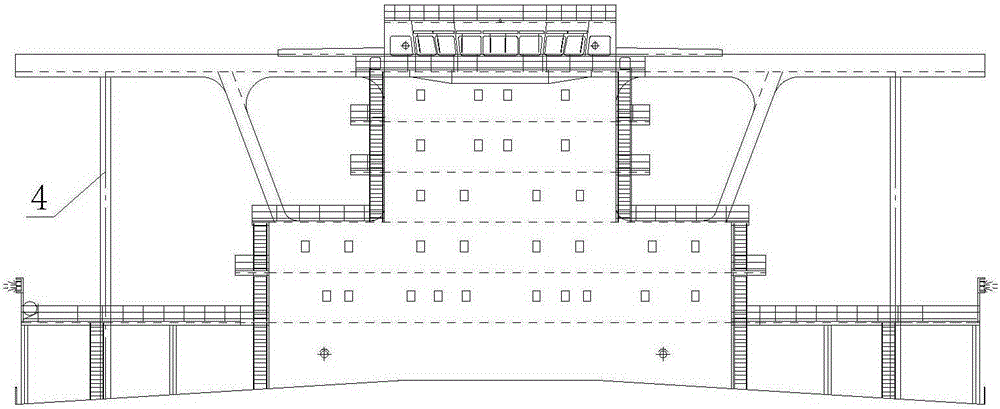

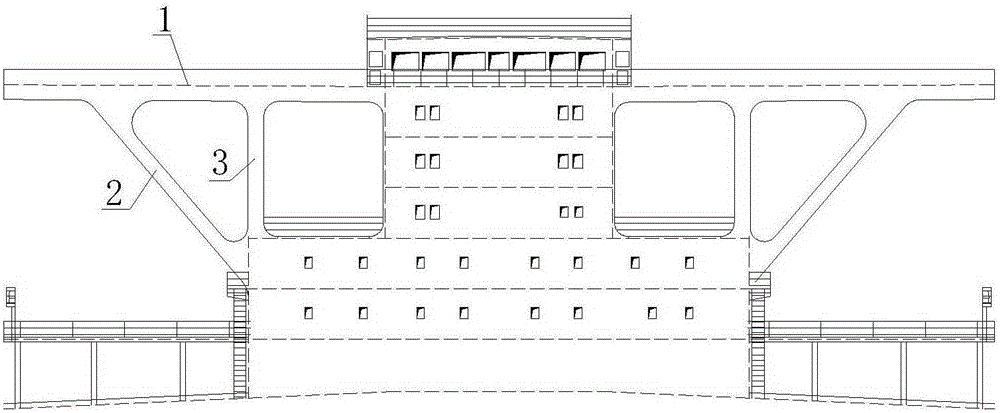

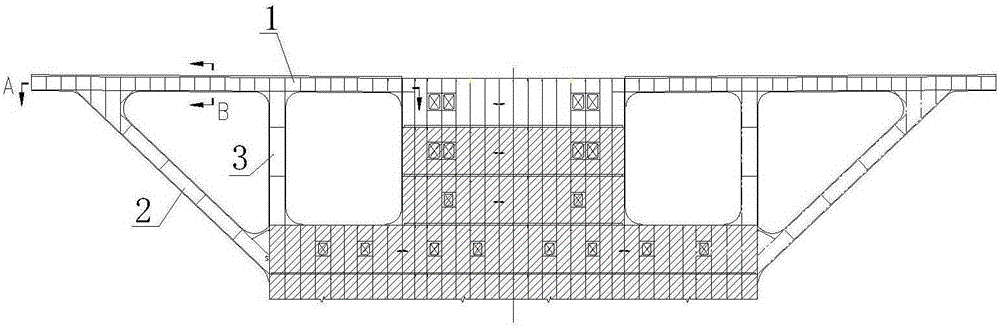

[0022] combine Figure 2 to Figure 7 As shown, a bridge wing structure of an ultra-large ore ship includes a bridge wing deck 1 arranged transversely along the hull. Preferably, the bridge wing deck is vertically composed of double-layer plates. A vertical support 3 is fixed under the wing deck, and a wing brace 2) is fixed between the vertical support and the wing deck. Form a triangular structure horizontally. The support point where the wing brace 2 is connected to the wing deck 1 is close to the maximum width of the wing, and the angle between the wing brace 2 and the horizontal direction is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com