Proportional pressure brake control valve

A pressure control and proportional technology, applied in the direction of control valves, air release valves, brakes, brake components, etc., can solve the problems of large outlet pressure, increased volume and weight of the electromagnet, and high price, so as to reduce the output Force, volume and weight reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present application are described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present application may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not relevant to the present application and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

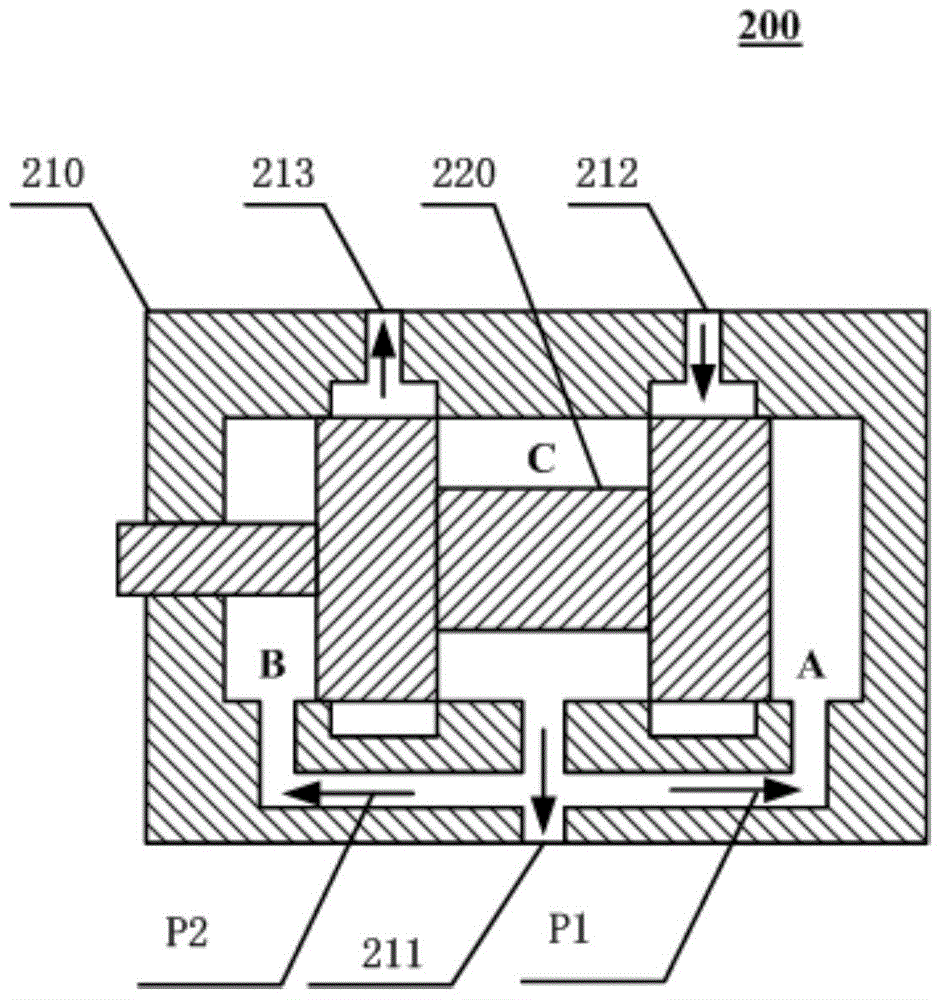

[0031] see figure 2 Shown is a schematic structure diagram 200 of an embodiment of the proportional pressure control valve of the present application.

[0032] In this embodiment, the proportional pressure control valve includes a valve body 210 and an asymmetric piston 220 located in the valve body.

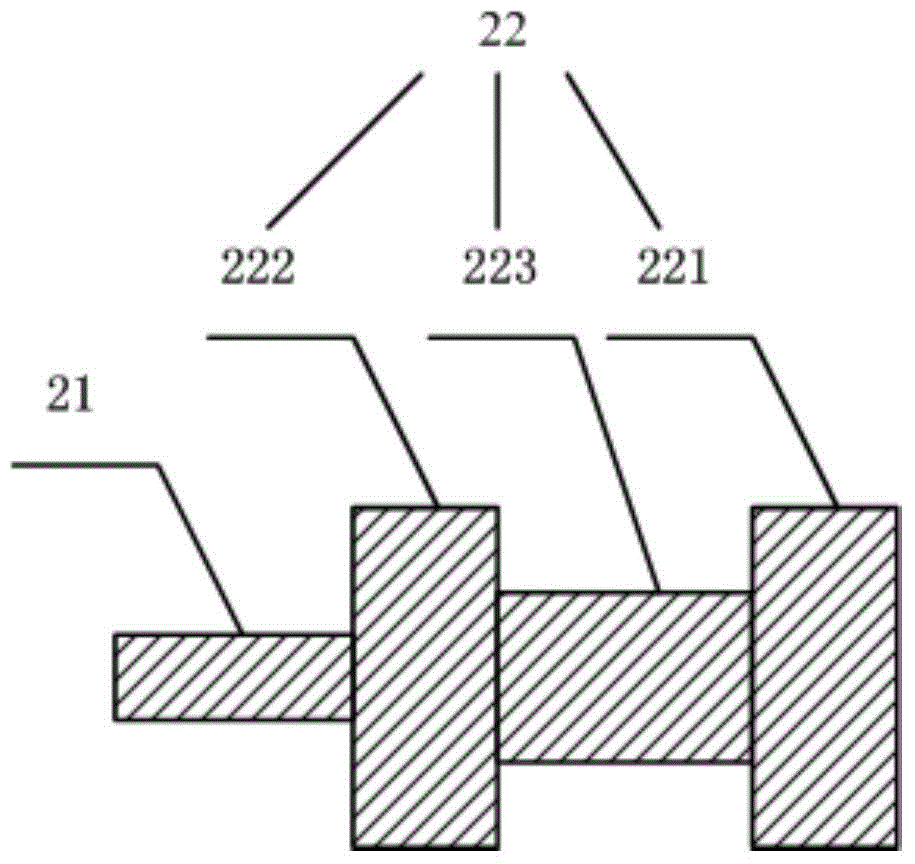

[0033] see image 3 shown, for figure 2 A schematic structural diagram of the asymmetric piston 220 in .

[0034] The asymmetric piston 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com