One-time injection molding method for totally-cladded plastic product

A technology for injection molding and plastic products, applied in the direction of coating, etc., can solve the problems of increasing operation steps, complex injection molding process, unfavorable production efficiency, etc., and achieve the effects of increasing production efficiency, reducing costs, and simple device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The claimed subject matter can be described in more detail with reference to the following implementation examples. These examples are exemplary and the claimed subject matter is not to be considered limited to the materials, conditions or process parameters given in the examples. All parts and percentages are by weight unless otherwise indicated.

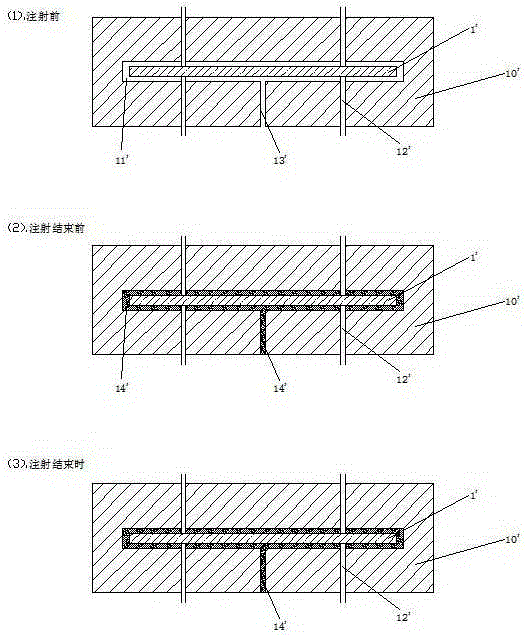

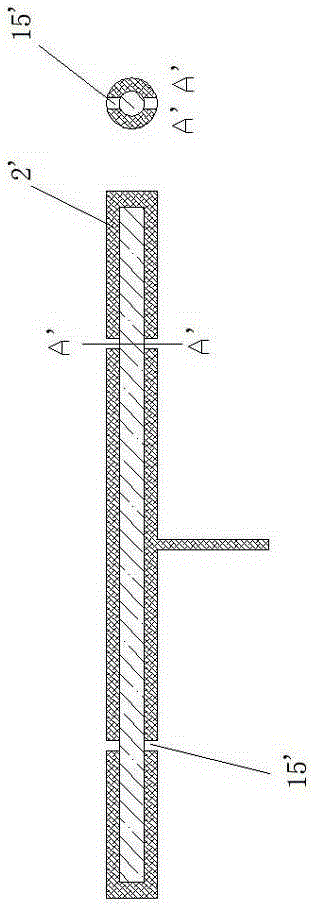

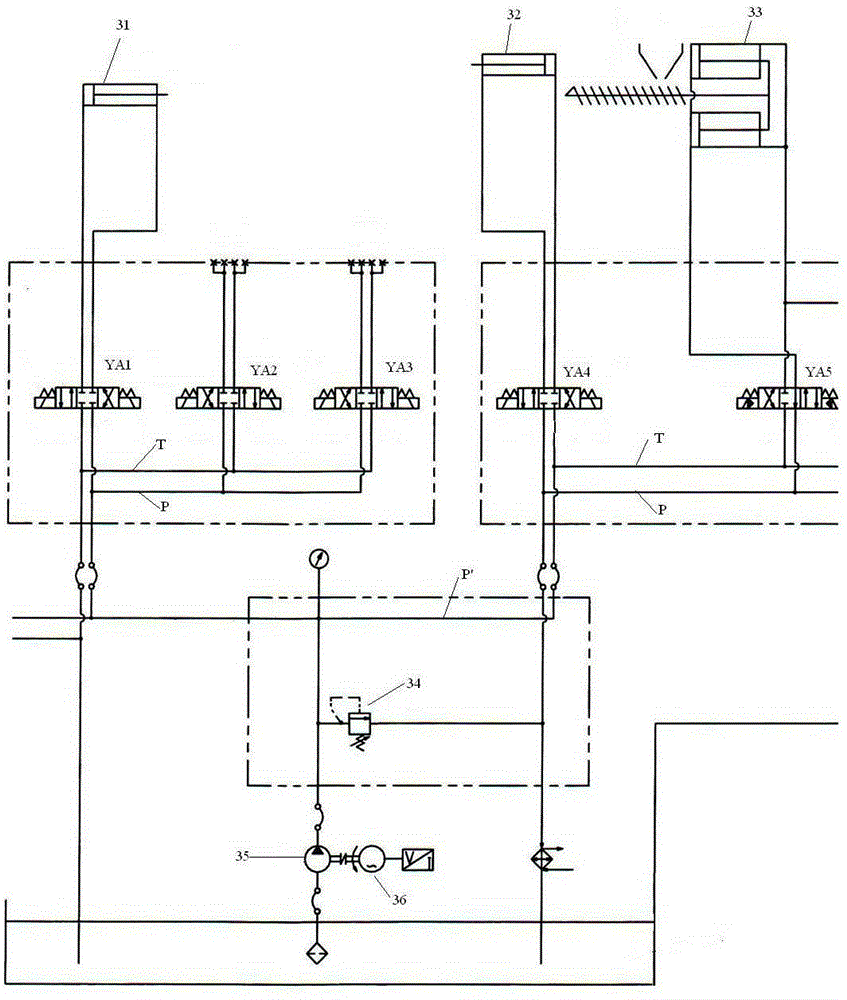

[0032] Figure 4 A method of manufacturing a long rod-shaped product 2 completely covering a long rod-shaped metal core 1 according to an embodiment of the present invention is shown, Figure 5 Represent the product 2 that this method obtains, can find out from the figure that there is not any cavity on the surface of product 2, and this method comprises the following steps:

[0033] (1) Before injection (before the two half-molds 10 are closed), use several symmetrically arranged support rods 12 to fix the long rod-shaped metal core 1 to be coated in the middle of the cavity 11 to be formed after the closing;

[0034] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com