Highly-throwing rice sieving machine

A screening machine and high-throwing technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve problems such as large influence of human factors, large labor consumption, and rice cannot be scattered. Achieve thorough screening and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

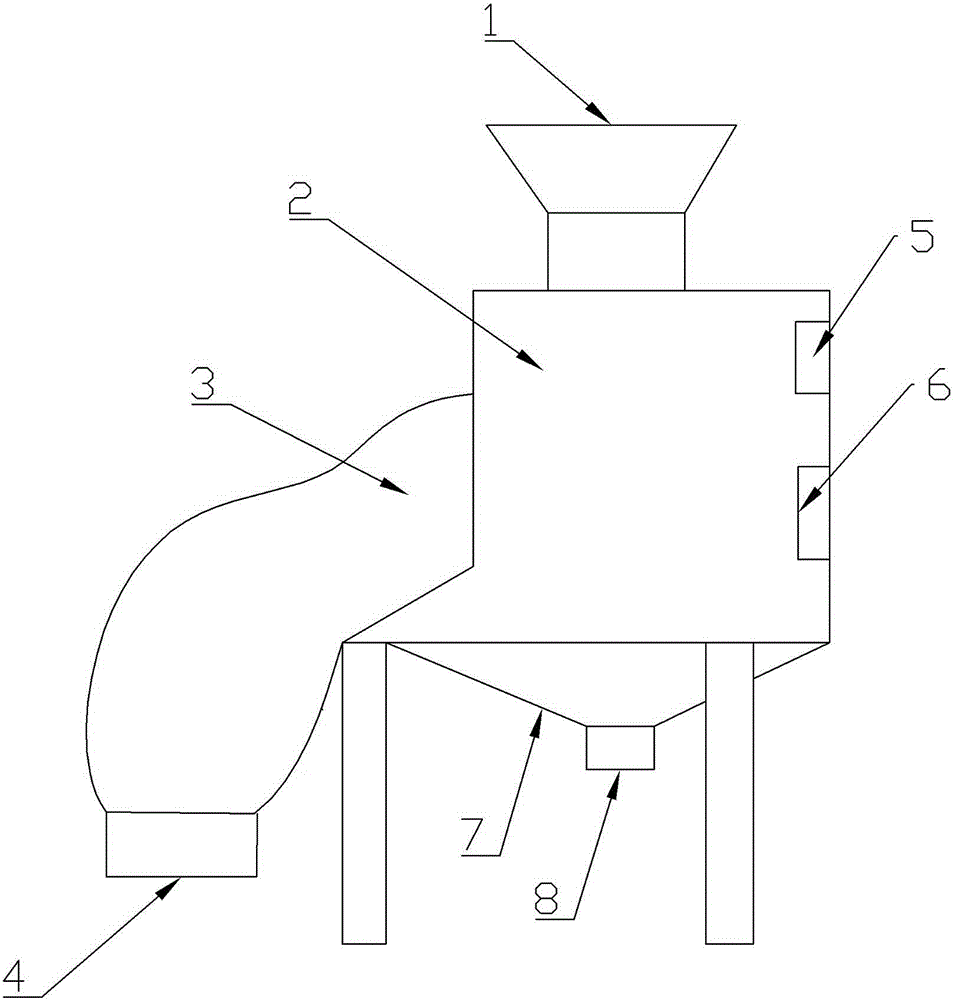

[0013] The reference signs in the drawings of the description include: feed inlet 1 , high throw rack 2 , empty shell bag 3 , empty shell mouth 4 , first fan 5 , second fan 6 , funnel 7 , and discharge port 8 .

[0014] The embodiment is basically as attached figure 1 Shown: including the high throwing frame 2, the high throwing frame 2 is a telescopic structure in the vertical direction, and the height of the high throwing frame 2 can be adjusted through telescopic adjustment. The distance is 1m, and when the high throw frame 2 stretches to the highest, the distance between the high throw frame 2 top and the bottom end is 3m. The top of the high throwing frame 2 is provided with a feed inlet 1, and the bottom end of the high throwing frame 2 is provided with a funnel 7, and the bottom of the funnel 7 is a discharge port 8; The opening is covered with an empty shell bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com