Gravel screening vehicle

A screening and gravel technology, applied in clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc., can solve the problem of large screening capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

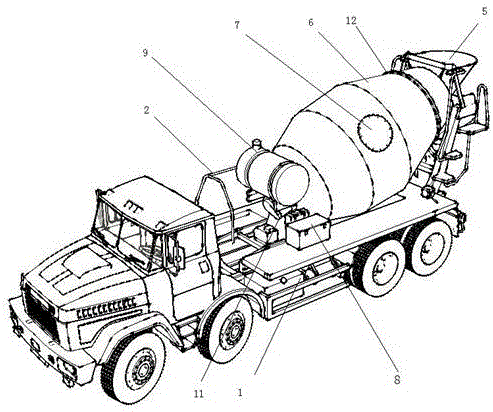

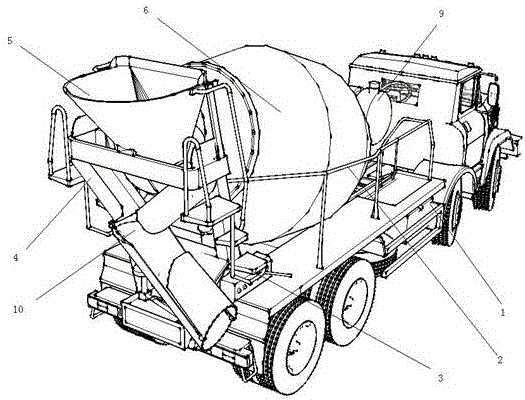

[0015] The invention provides a sand and gravel screening truck. The vehicle body adopts a special truck design similar to a concrete mixer truck. The upper part is equipped with a mixing drum, and there is a sand screening bucket in the mixing drum, which can be rotated during transportation to screen sand and gravel. So as to achieve the purpose of screening sand and gravel during transportation.

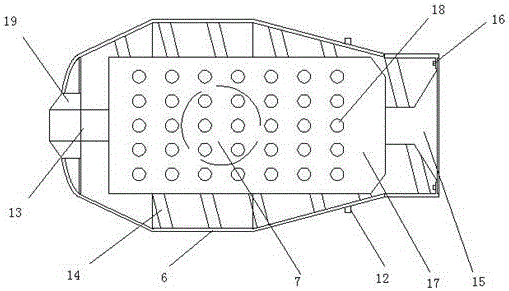

[0016] As an embodiment of the present invention, the present invention provides a gravel screening vehicle, including a car body 1, a staircase 3, a discharging mechanism 4, a feeding hopper 5, a mixing drum 6, a battery box 8, a hydraulic device 9, and a movable The discharging pipe 10, the rotating mechanism 11, the rotating shaft 13 and the screening bucket 17, the vehicle body 1 has a mixing drum 6 on the body, the mixing drum 6 is placed obliquely, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com