Filter material, pleat processing method thereof, and air filter for air cleaner

An air purifier and air filter technology, which is applied in separation methods, filtration separation, and dispersed particle filtration, etc., can solve the problems of structural resistance increase and achieve the effect of trapping performance suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the pleating processing method of the filter medium for air filters, the filter medium for air filters, and the air filter for air cleaners of this invention are demonstrated.

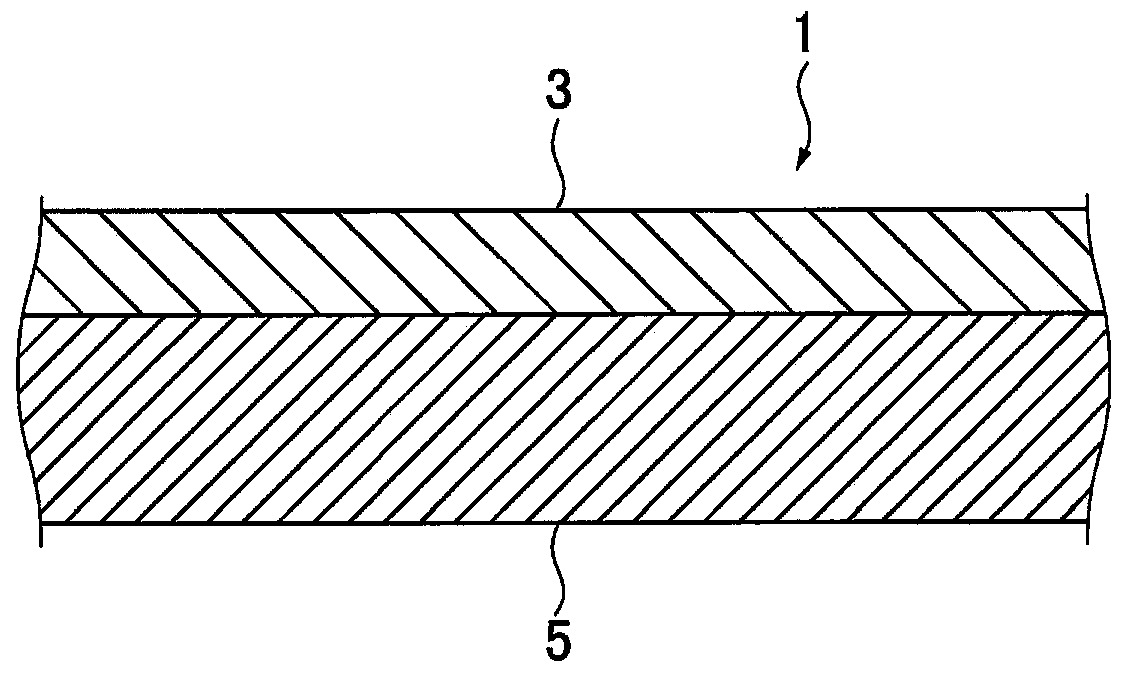

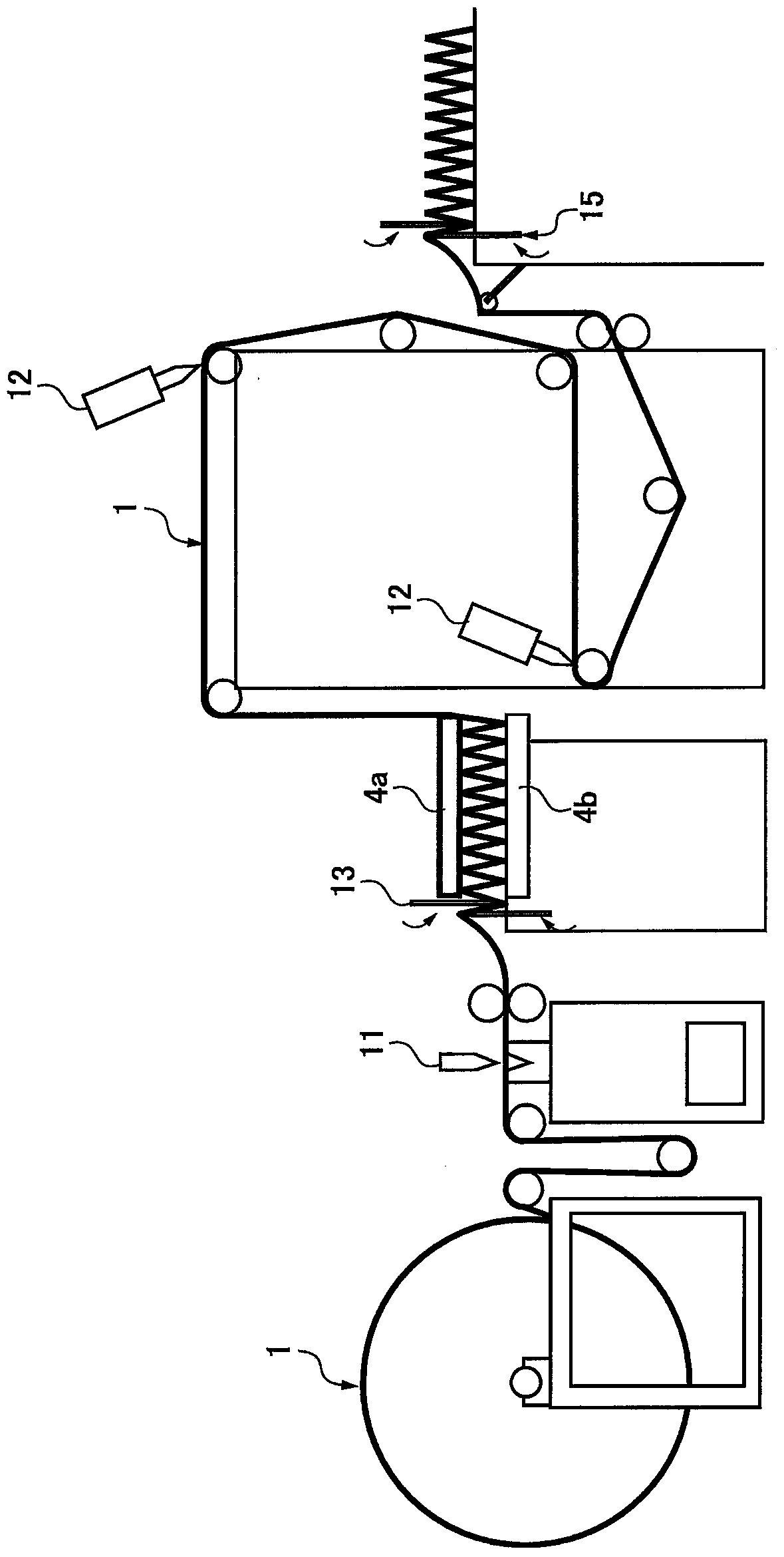

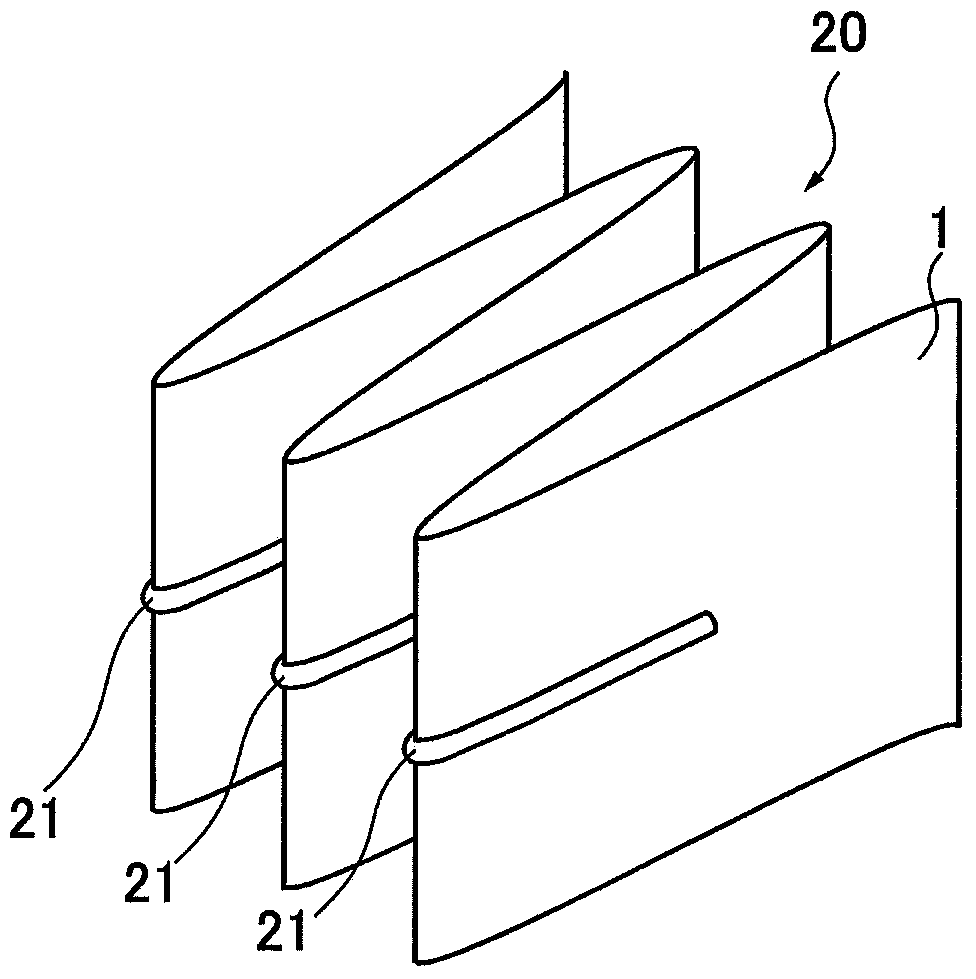

[0042] The method for processing a filter medium for an air filter according to the present embodiment includes a step of subjecting a filter medium for an air filter (hereinafter, also referred to as a filter medium) to a pleating process, wherein the filter medium for an air filter has a melt-blown non-woven fabric. The collection layer composed of woven cloth has the stiffness and softness (hereinafter, stiffness and softness) of the filter medium for air filters measured by the Gurley method described in JIS-L1085-6.10.3 exceeding 6 mN, and is implemented electret treatment. In the step of implementing this pleating process, the filter medium is subjected to compression heat treatment under the conditions of more than 80° C. and 90° C. or lower and for 15 minutes to 30 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com