Making method of green tea flavored syrup

A production method and flavor technology, applied in the direction of tea, tea extraction, tea treatment before extraction, etc., can solve the problems of thin taste, dull aroma and taste of cooked soup, time-consuming and labor-intensive, etc., to achieve convenient transportation and storage, bright yellow-green color , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

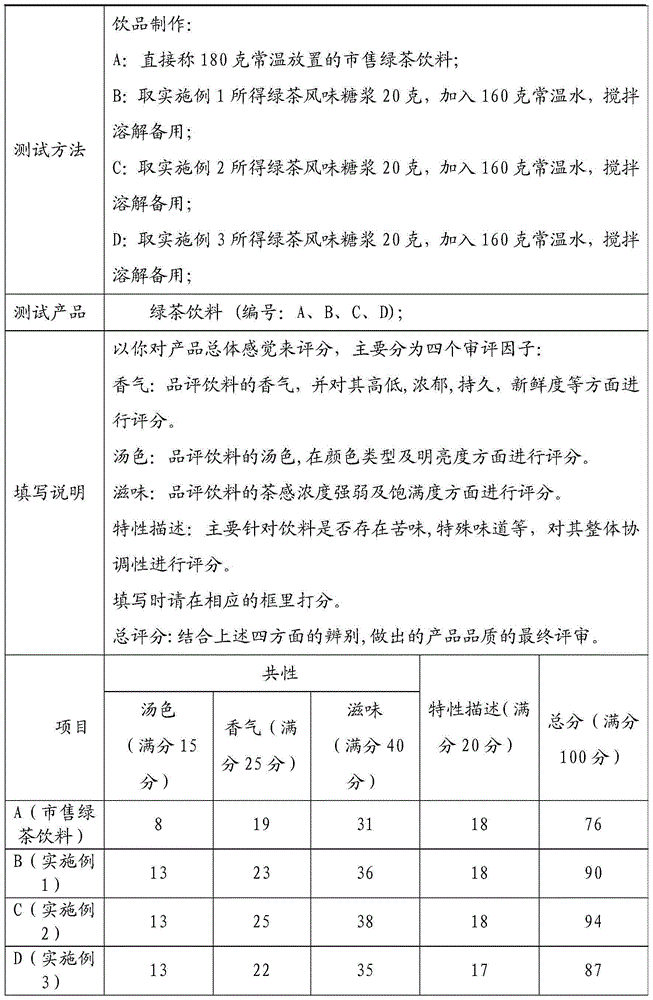

Examples

Embodiment 1

[0041] A preparation method of green tea flavor syrup, comprising the steps of:

[0042] 1) Extraction: Select high-quality green tea, add pure water, water temperature 40°C, add pure water and 2% sodium erythorbate of the weight of the tea leaves for extraction, the ratio of solid to liquid is 1:6g / L, the extraction time is 35min, and it is obtained after filtration Extraction solution;

[0043] 2) Enzymolysis: Add sodium bicarbonate solution to the extract obtained in step (1) to adjust the pH of the extract to 5.5, then add β-glucosidase to carry out an enzymolysis, the β-glucosidase in the first enzymolysis The amount of enzyme added is 10 mg / kg feed liquid, the enzymolysis temperature is 45-55°C, and the enzymolysis time is 2 hours. After one enzymolysis, filter, add 4 times pure water to the filtered tea dregs, and use sodium bicarbonate solution to dissolve Adjust the pH of the filter residue to 5.0, then add pectinase and cellulase for secondary enzymolysis, the amoun...

Embodiment 2

[0048] A preparation method of green tea flavor syrup, comprising the steps of:

[0049] 1) Extraction: Select high-quality green tea, add pure water, water temperature 40°C, add pure water and 2% sodium erythorbate of the weight of the tea leaves for extraction, the ratio of solid to liquid is 1:7g / L, the extraction time is 35min, and it is obtained after filtration Extraction solution;

[0050] 2) Enzymolysis: Add sodium bicarbonate solution to the extract obtained in step (1) to adjust the pH of the extract to 5.5, then add β-glucosidase to carry out an enzymolysis, the β-glucosidase in the first enzymolysis The amount of enzyme added is 35 mg / kg feed liquid, the enzymolysis temperature is 45-55°C, and the enzymolysis time is 2 hours. After one enzymolysis, filter, add 4 times of pure water to the filtered tea dregs, and use sodium bicarbonate solution to dissolve Adjust the pH of the filter residue to 5.0, then add pectinase and cellulase for secondary enzymolysis, the am...

Embodiment 3

[0055] A preparation method of green tea flavor syrup, comprising the steps of:

[0056] 1) Extraction: Select high-quality green tea, add pure water, water temperature 45°C, add pure water and 2% sodium erythorbate of the weight of the tea leaves for extraction, the ratio of solid to liquid is 1:9g / L, the extraction time is 35min, and obtained after filtration Extraction solution;

[0057] 2) Enzymolysis: Add sodium bicarbonate solution to the extract obtained in step (1) to adjust the pH of the extract to 5.5, then add β-glucosidase to carry out an enzymolysis, the β-glucosidase in the first enzymolysis The amount of enzyme added is 50 mg / kg feed solution, the enzymolysis temperature is 45-55°C, and the enzymolysis time is 2 hours. After one enzymolysis, filter, add 4 times of pure water to the filtered tea dregs, and use sodium bicarbonate solution to dissolve Adjust the pH of the filter residue to 5.0, then add pectinase and cellulase for secondary enzymolysis, the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com