Method for the production of hyperbranched polyglycerol

A technology of polyglycerol and glycerin, which is applied in chemical instruments and methods, chemical/physical processes, catalyst activation/preparation, etc., can solve the problems of unreported hyperbranched polyglycerol and poor activity of CaO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

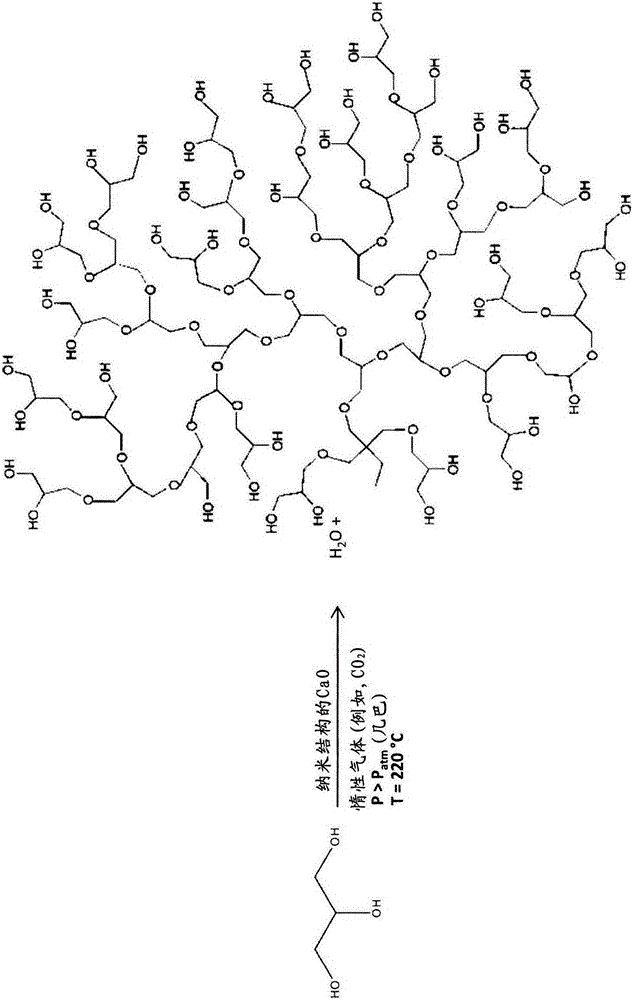

[0028] As discussed in the background section, the glycerol polycondensation processes known hitherto for the production of dendritic polyglycerols generally have rather low yields and either have to be carried out in the gas phase or dispersed in solvents or aqueous media. The present invention proposes a new method of producing hyperbranched polyglycerol from glycerol, said method comprising the following steps:

[0029] (a) adding glycerol and CaO-based catalyst to the vessel,

[0030] (b) pouring an inert gas, preferably carbon dioxide, into the resulting mixture, and sealing the reaction vessel to form a pressure of 1 to 10 bar above atmospheric pressure, preferably 2 to 6 bar above atmospheric pressure;

[0031] (c) heating the reaction mixture at a reaction temperature of at least 100°C but below the boiling point of the reaction mixture;

[0032] (d) maintaining said reaction conditions until at least 40% by weight of the glycerol undergoes polycondensation and conver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com