Trench MOSFET with double tube cores and production method of Trench MOSFET

A processing method and dual-die technology, applied in the direction of transistors, electrical components, electric solid-state devices, etc., can solve the problems of TrenchMOSFET with large area, and achieve the effect of increasing the number of effective dies, reducing the area, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

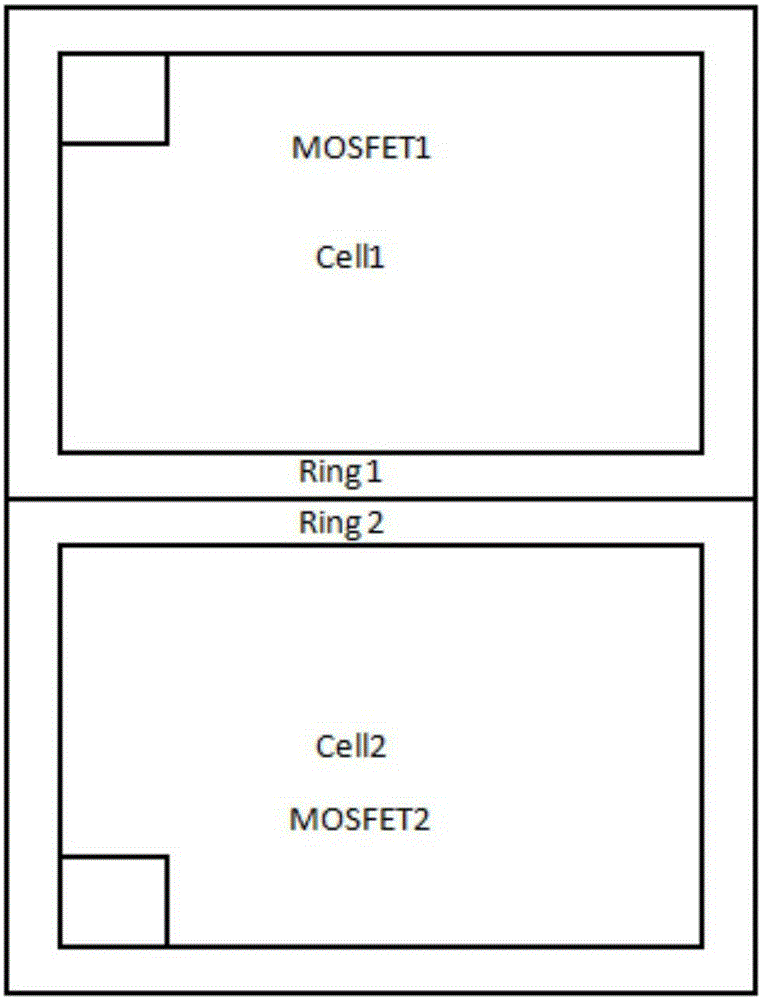

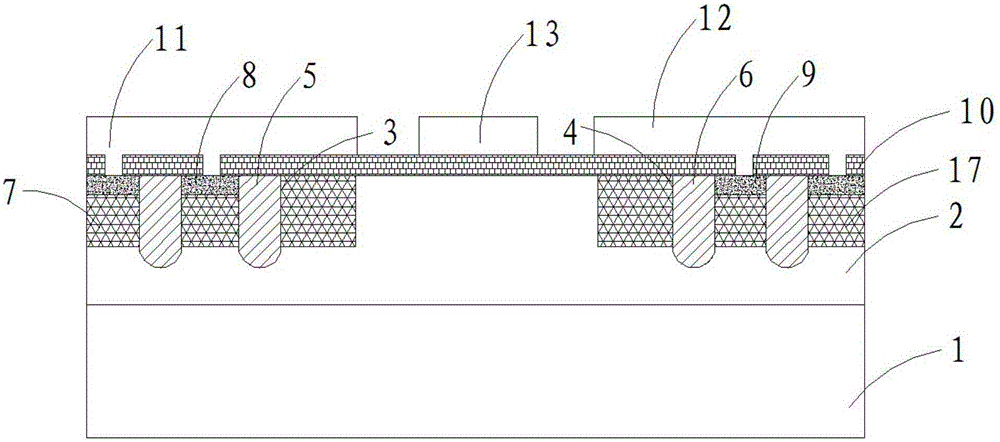

[0024] see Figure 2 to Figure 6 , The present invention provides a dual-die Trench MOSFET, wherein the MOSFET is a metal-oxide semiconductor field-effect transistor, referred to as a metal-oxide-semiconductor field-effect transistor (Metal-Oxide-Semiconductor Field-Effect Transistor, MOSFET). Including an N+ substrate layer 1, an N- epitaxial layer 2 is arranged on the N+ substrate layer, a first P-body layer 7 is arranged on the upper left part of the N- epitaxial layer, and a second P-body layer 17 is arranged on the upper right part of the N- epitaxial layer, Between the first P-body layer and the second P-body layer is a continuous N-epitaxial layer, that is, there is no P-body layer between the first P-body layer and the second P-bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com