Backstepping control method for nanoelectromechanical systems with output constraints and dead-zone inputs

A nano-electromechanical system, output constraint technology, applied in the direction of program control, adaptive control, general control system, etc., can solve the problems of chaotic control of nano-electromechanical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

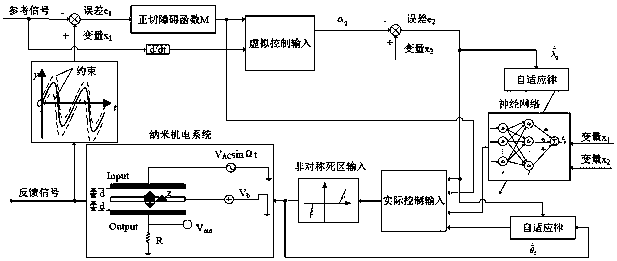

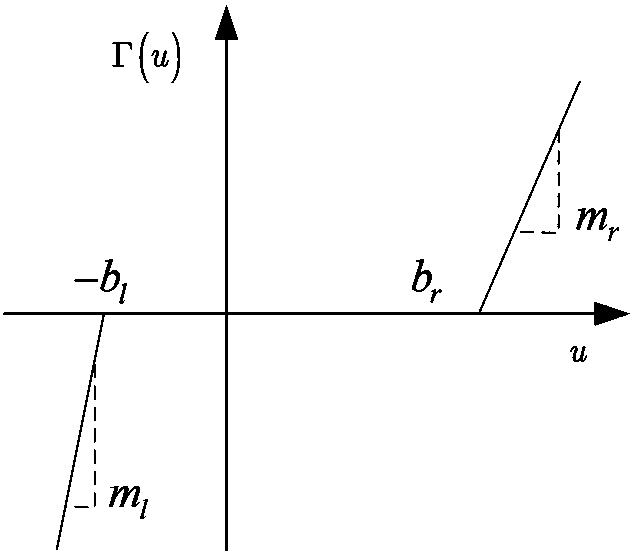

Method used

Image

Examples

Embodiment

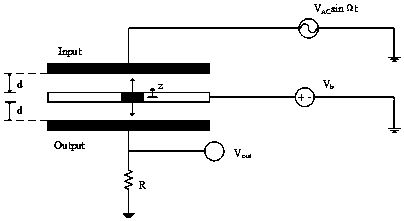

[0177] Embodiment: In order to effectively suppress the chaotic oscillation of the nano-electromechanical system, first analyze its chaotic behavior in a dimensionless form; the nano-electromechanical system parameter value is V AC ∈(0,0.47), α=1, β=12, γ=0.338, μ=0.01, V b =3.8 and ω=0.5; in the initial condition (x 1 ,x 2 )=(0,0) and fixed bias voltage, the phase diagram and time history of the system are as follows Figure 8 shown; from Figure 8 (a) It can be seen that instantaneous chaos and regular motion appear near the center point near the origin; from Figure 8 (b) It can be seen that at V AC =0.045, beam oscillation appears near other central points; from Figure 8 (c) It can be seen that the regular motion produces homoclinic orbits after the transient chaotic response, and the amplitude of harmonic oscillation is obviously larger than Figure 8 (a)-(b); At this time, due to the influence of two unstable points near the fixed electrodes, the dynamic behavior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com