Centrifugal pump of front-mounted cyclone type gas-liquid separator

A gas-liquid separator and centrifugal pump technology, applied in the field of centrifugal pumps, can solve problems such as difficult separation of dissolved gases and complicated use, and achieve the effect of improving the effect and strong degassing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

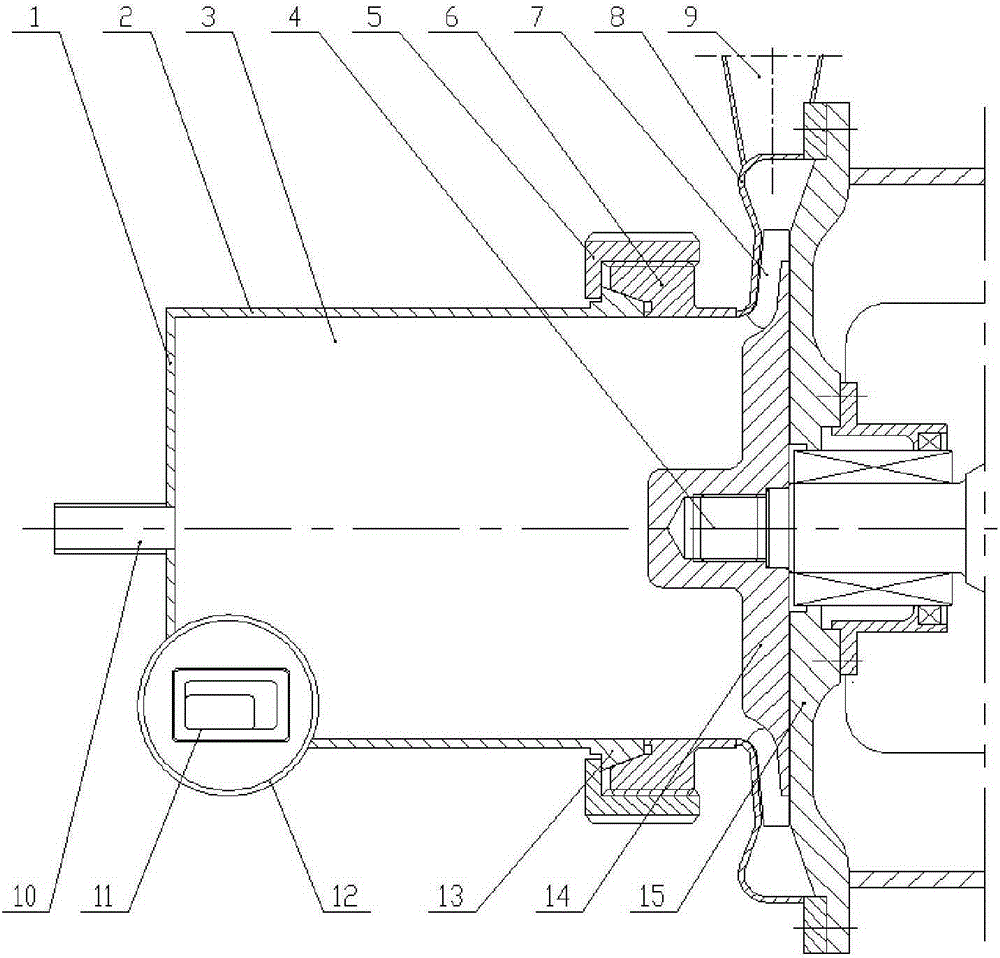

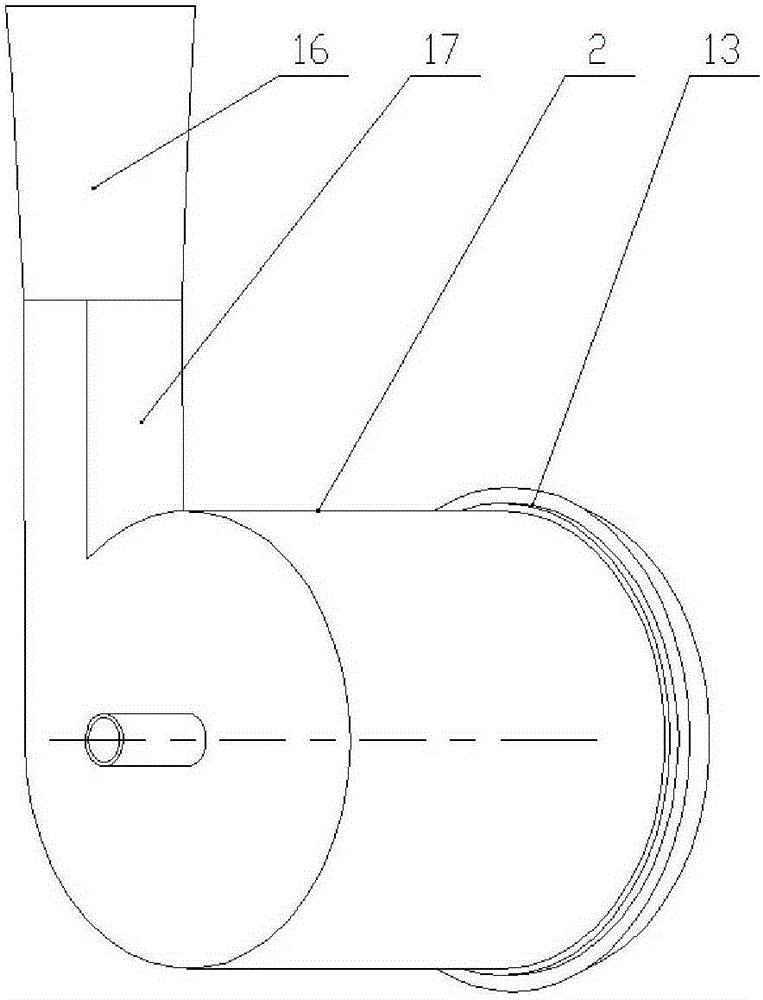

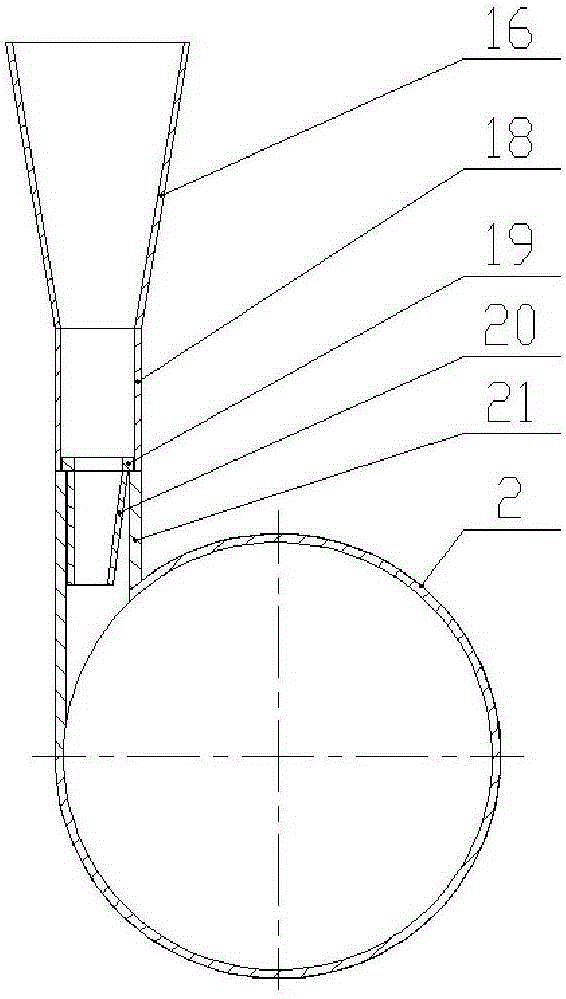

[0031] Such as Figure 1~5 As shown, the centrifugal pump of the pre-cyclone gas-liquid separator in this embodiment includes: a centrifugal pump and a cyclone cylinder 3 connected to each other.

[0032] The centrifugal pump includes a volute 8 with an axial inlet and a built-in pump shaft 4, and an impeller 14 fixedly connected to the pump shaft 4 for discharging liquid in the volute 8. An outlet 9 (tangential outlet) is provided above the volute 8. The end cover of the volute 8 is a connecting frame 15, the impeller 14 is provided with a blade 7 facing the side of the swirl tube 3, the gap between the blade 7 and the inner wall of the volute 8 is 0.5mm, and the side of the impeller 14 away from the swirl tube 3 is connected to the The gap of frame 15 is 0.5mm, and blade 7 is an open blade, gets 6 in the present embodiment.

[0033] The swirl tube 3 includes an end cap 1 and a cylinder wall 2. The open end of the swirl tube 3 is connected with a threaded joint 13, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com