Microscopic dynamic monitoring device and repair method for micron-scale cracks in painted layer of ceramic cultural relics

A technology for dynamic monitoring of ceramic cultural relics, applied in the field of restoration of painted cultural relics, can solve problems such as shedding, neglect of repair research on cracks and diseases, cracks in painted layers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] like figure 1 As shown, the microscopic dynamic monitoring device for micron-scale cracks in the painted layer of ceramic cultural relics in this embodiment consists of an adjusting screw 1, a fixed plate 2, a mounting frame 3, a lens 4, a lens clip 5, a tripod 6, an optical fiber 7, a base 8, The rotating shaft 9, the image processor 10, and the workbench 11 are connected to form, wherein the base 8, the mounting frame 3, the rotating shaft 9, the fixing plate 2, the adjusting screw 1, and the mounting frame 3 are connected to form a repair table.

[0032] An image processor 10 is placed on the left side of the workbench 11, and a tripod 6 is placed on the right side of the workbench 11. The tripod 6 is a commodity sold on the market. The tripod 6 has a horizontal adjustment handle and a vertical adjustment handle. A lens clamp 5 is fixedly connected with a threaded fastening connector, and a lens 4 is fixedly installed on the lens clamp 5, and the horizontal adjustmen...

Embodiment 2

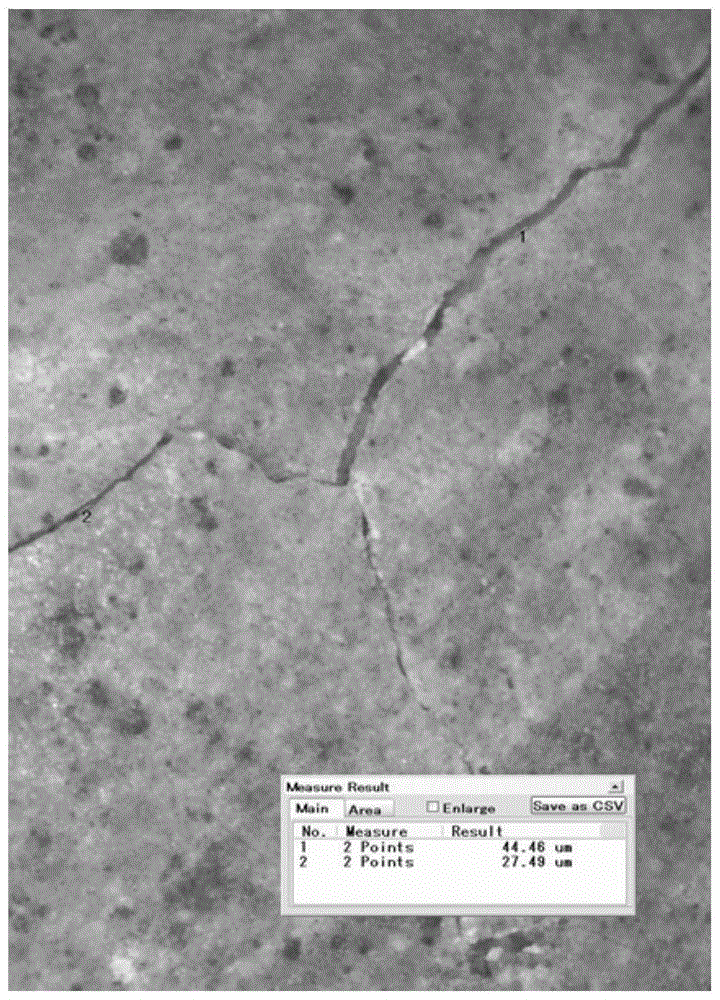

[0041] The microscopic dynamic monitoring device for micron-scale cracks in the painted layer of pottery cultural relics in this embodiment is the same as in Example 1. The step 1 of using this device to repair the micron-scale cracks in the painted layer of pottery figurines is the same as in Example 1. In the step 2 of repairing cracks, Gently blow away the dust in the micron-sized cracks of the painted layer of the terracotta figurines with an ear-absorbing ball, and accurately measure the length and width of the cracks. 3 The amount of patch repair agent is injected into the crack with a syringe or dipped in the patch repair agent with a cotton swab and repeatedly dipped in the crack. The paste repair agent is composed of 1% ZB-F600 two-component FEVE water-based The fluororesin aqueous solution is mixed with 1% water-soluble epoxy resin B-63 and absolute ethanol in a volume ratio of 1:1:10. After the painted layer at the crack is wet, use a soft rubber ball to squeeze the...

Embodiment 3

[0044] The microscopic dynamic monitoring device for micron-scale cracks in the painted layer of pottery cultural relics in this embodiment is the same as in Example 1. The step 1 of using this device to repair the micron-scale cracks in the painted layer of pottery figurines is the same as in Example 1. In the step 2 of repairing cracks, Gently blow away the dust in the micron-scale cracks of the painted layer of the terracotta figurines with an ear-absorbing ball, and accurately measure the length and width of the cracks. 3 The amount of patch repair agent is injected into the crack with a syringe or dipped in the patch repair agent with a cotton swab and repeatedly dipped in the crack. The paste repair agent is composed of 4% ZB-F600 two-component FEVE water-based The fluororesin aqueous solution is mixed with 0.6% water-soluble epoxy resin B-63 and absolute ethanol in a volume ratio of 1:3:12. After the painted layer at the crack is wet, use a soft rubber ball to squeeze t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com