Separation method of PbO, PbSO4 and PbO2 mixture

A separation method and mixture technology, which are applied in the preparation of lead compounds, lead sulfate, lead oxide, etc., can solve the problems of consuming chemical reagents, affecting economic benefits, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

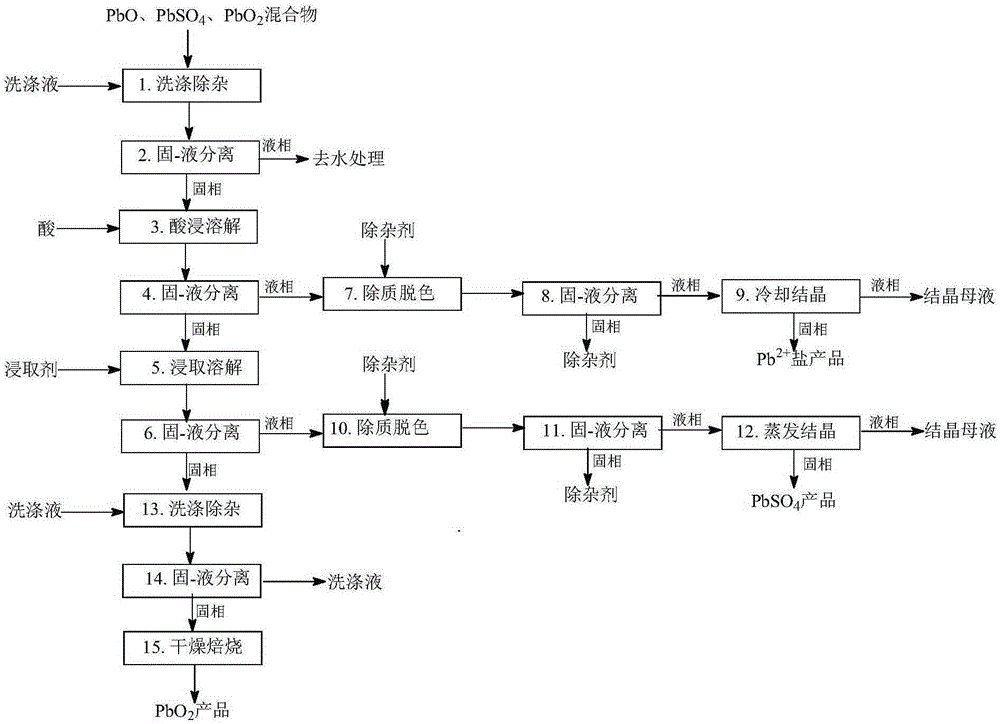

[0122] like figure 1 As shown, a PbO, PbSO 4 , PbO 2 The separation method of the mixture, especially the PbO and PbSO obtained by physical separation from the lead-containing materials of waste lead-acid batteries 4 , PbO 2 The lead paste of the mixture is used as the raw material, and the acid leaching and dissolving, leaching and dissolving, separation and refining, and solid-liquid separation coupling technologies are used to realize PbO and PbSO 4 , PbO 2 Separation of mixtures. It is characterized in that the method steps are as follows:

[0123] (1) Washing and impurity removal: PbO, PbSO 4 , PbO 2The mixture is washed to remove impurities and remove soluble impurities. The washing and removing impurities used in the washing and removing impurities is water, and the amount of water added is that the mass ratio of solid phase material to washing and removing impurities is 1:1. The material goes to the next step;

[0124] (2) Solid-liquid separation: In the subme...

Embodiment 2

[0139] like figure 1 As shown, a PbO, PbSO 4 , PbO 2 The separation method of the mixture, especially the PbO and PbSO obtained by physical separation from the lead-containing materials of waste lead-acid batteries 4 , PbO 2 The lead paste of the mixture is used as the raw material, and the acid leaching and dissolving, leaching and dissolving, separation and refining, and solid-liquid separation coupling technologies are used to realize PbO and PbSO 4 , PbO 2 Separation of mixtures. It is characterized in that the method steps are as follows:

[0140] (1) Washing and impurity removal: In the tube scrubber washing and impurity removal equipment, PbO, PbSO 4 , PbO 2 The mixture is washed to remove impurities and remove soluble impurities. The washing and removing impurities used in the washing and removing impurities is methanol, and the total amount of the washing and removing impurities is that the mass ratio of the solid phase material to the washing and removing impu...

Embodiment 3

[0156] like figure 1 As shown, a PbO, PbSO 4 , PbO 2 The separation method of the mixture, especially the PbO and PbSO obtained by physical separation from the lead-containing materials of waste lead-acid batteries 4 , PbO 2 The lead paste of the mixture is used as the raw material, and the acid leaching and dissolving, leaching and dissolving, separation and refining, and solid-liquid separation coupling technologies are used to realize PbO and PbSO 4 , PbO 2 Separation of mixtures. It is characterized in that the method steps are as follows:

[0157] (1) Washing and impurity removal: In static mixing washing and impurity removal equipment, PbO, PbSO 4 , PbO 2 The mixture is washed to remove impurities and remove soluble impurities. The washing and removing impurities used in the washing and removing impurities is ethanol, and the total amount of the washing and removing impurities is that the mass ratio of the solid phase material to the washing and removing impuritie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com