Guiding device capable of directly receiving materials on ground in bulk cargo conveying process

A material guide device and ground technology, which is applied in the direction of transportation and packaging, packaging, loading/unloading, etc., can solve the problems of reducing the utilization rate of the storage yard, the parts of the vibrating feeder are easily damaged and blocked, and increasing the reclaiming distance. Achieve convenient and accurate receiving and unloading methods, reduce equipment failure rate, and simplify the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

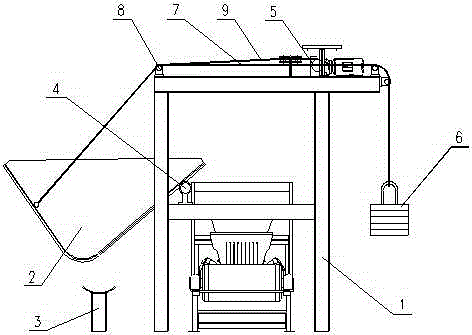

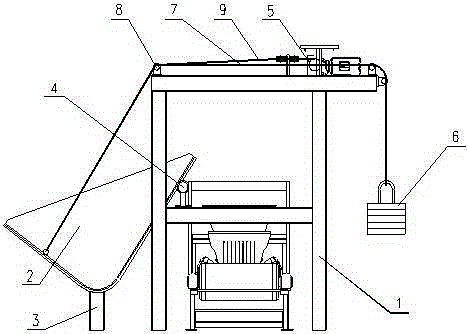

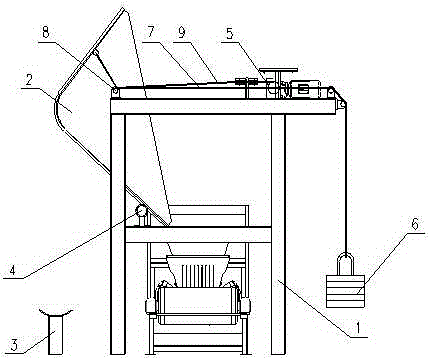

[0014] Referring to the accompanying drawings, a material guide device that can directly receive materials from the ground in the bulk material conveying process includes a bracket 1, a hopper 2, a hopper support 3, a hinge shaft 4, an electric reel 5, a counterweight 6, and a twisted rope 7 , fixed pulley 8, counterweight rope 9, support 1 spans above the material receiving section of the tape machine on the ground in the yard, and is used to fix the rotating hinge shaft and electric reel 5 of the hopper 2, and adopts the twisted rope 7 wound by the fixed pulley 8 and The counterweight rope 9 is used to pull the hoisting ring and the counterweight 6 of the hopper 2. The hopper 2 is set on one side of the belt conveyor on the ground and adopts a spoon-shaped structure. The hinge ring of the hopper and the hinge ring of the bracket 1 are hinged with the hinge shaft 4, and the lifting end of the hopper 2 is provided with a pull ring, which is fixed with the twisted rope 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com