Combined milling cutter used for graphite grooving

A combined milling cutter and milling cutter technology, which is applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems that multiple parallel grooves cannot be cut synchronously, the groove speed is slow, and the precision is low, so as to achieve the pollution of the working environment Less cutting speed, faster slotting speed, and higher processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

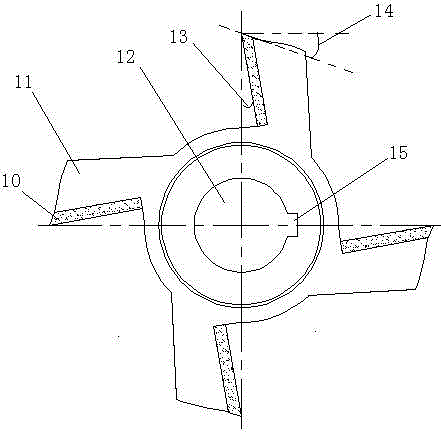

[0024] Such as figure 1 The composite milling cutter for graphite slotting shown has a cutter shaft and a multi-piece milling cutter. There is a keyway on the cutter shaft. The milling cutter is connected to the cutter shaft through a key. It has a cutter shaft and 18 pieces are sequentially set and connected to the cutter shaft. Milling cutter, the milling cutter is a three-sided edge milling cutter, each milling cutter has 4-8 cutter heads; one end of the cutter shaft is fixedly connected with a drive turntable, and the other end of the cutter shaft is connected with a bearing supporting the cutter shaft;

[0025] There is a spacer ring between each milling cutter to adjust the spacing and positioning between milling cutters; each milling cutter has a set rotation angle of 10°-20° relative to adjacent milling cutters.

[0026] The diameter of each milling cutter at the two ends of the cutter shaft is smaller than that of the milling cutters at other positions.

[0027] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com