Electric polishing machine tool

An electric, machine tool technology, applied in the direction of gear cutting machines, mechanical equipment, gear teeth, etc., can solve the problems of affecting gear quality, low degree of automation, slow processing speed, etc., to improve efficiency and gear quality, save manpower and material resources, The effect of increasing economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the content, features and effects of the present invention, the following examples are given in detail as follows:

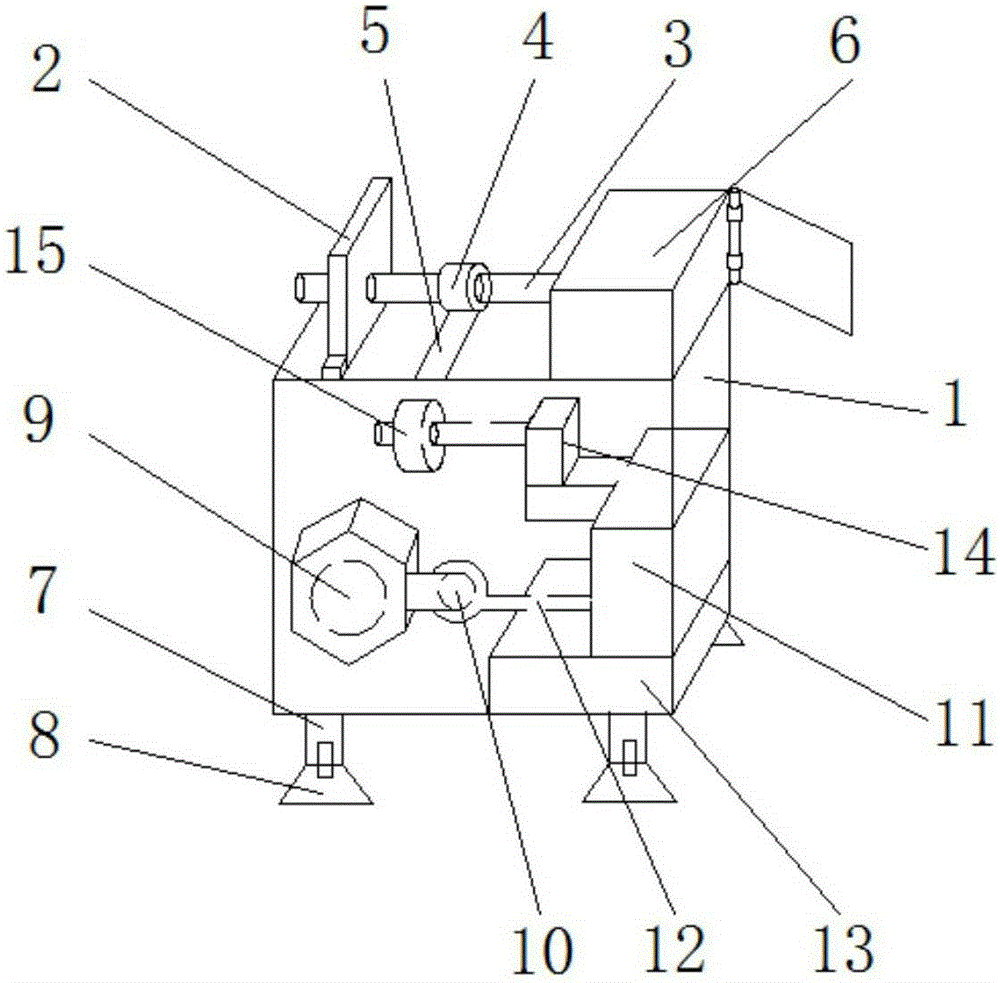

[0013] See figure 1 , The present invention includes the main body 1, the bearing turret 2, the bearing 3, the follower 4, the rotating belt 5, the processing box 6, the supporting table leg 7, the stabilizer seat 8, the high-power generator 9, the electric power output device 10, and the engine box 11. , Transmission line 12, intelligent positioning device 13, tachometer placement frame 14, and main tachometer 15. among them,

[0014] A bearing turret 2 is installed on the upper side of the main body 1, and a bearing 3 is installed on the bearing turret 2, a follower 4 is installed on the bearing 3, and a rotating belt 5 is installed on the upper side of the follower 4, and the right side of the bearing 3 is installed in the processing box Inside 6, the supporting leg 7 is arranged on the underside of the main body 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com