Multifunctional aluminum ladle cleaning machine

A cleaning machine, multi-functional technology, applied in mechanical cleaning, manufacturing tools, metal processing equipment and other directions, can solve the problems of high labor intensity, low production efficiency, and high cost of tool replacement for workers, reducing labor intensity and reducing labor costs. The effect of maintenance cost and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

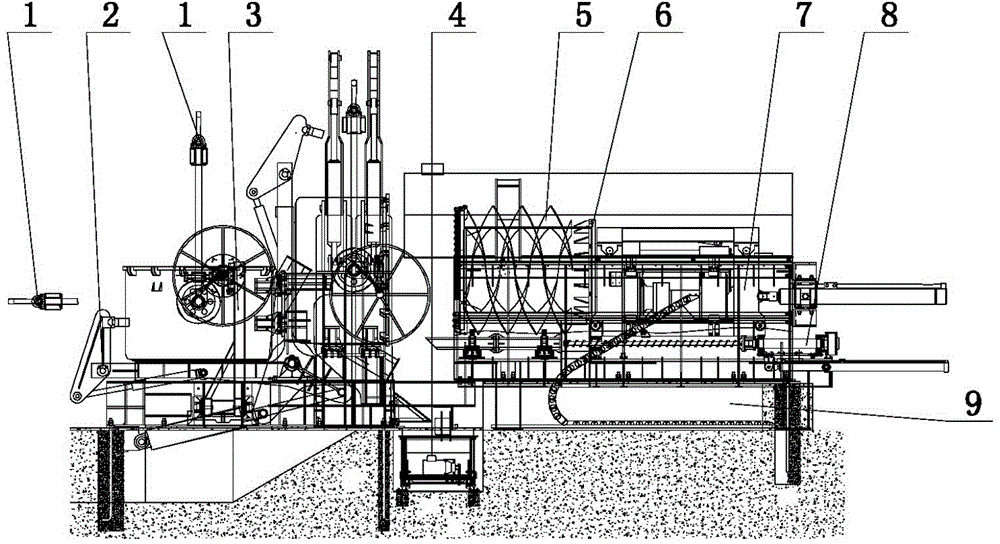

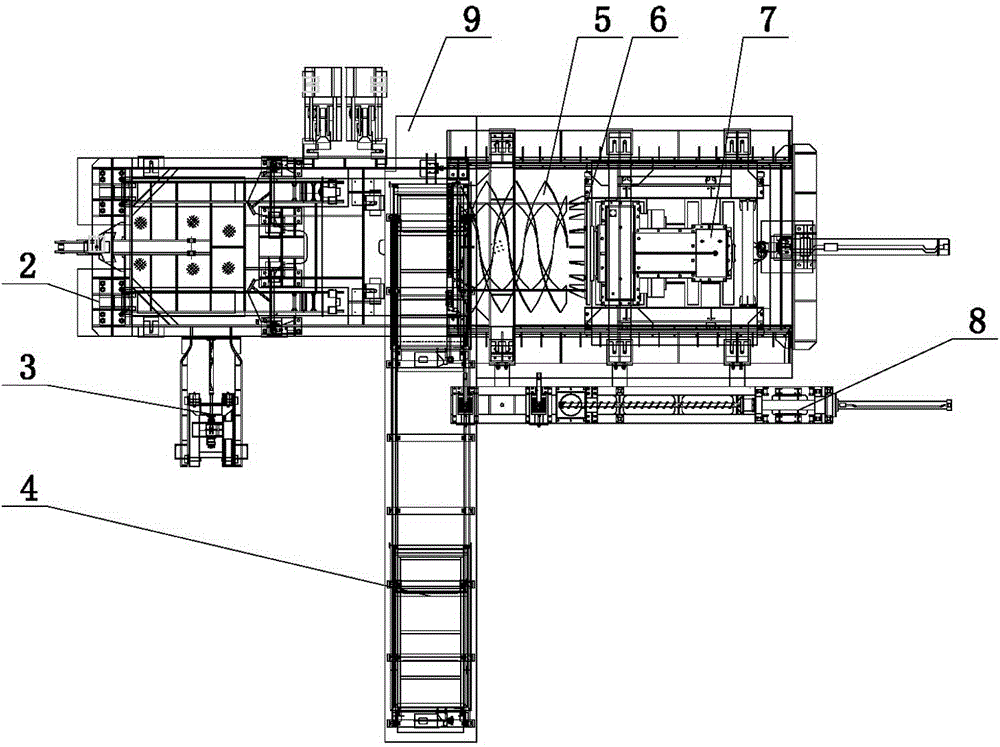

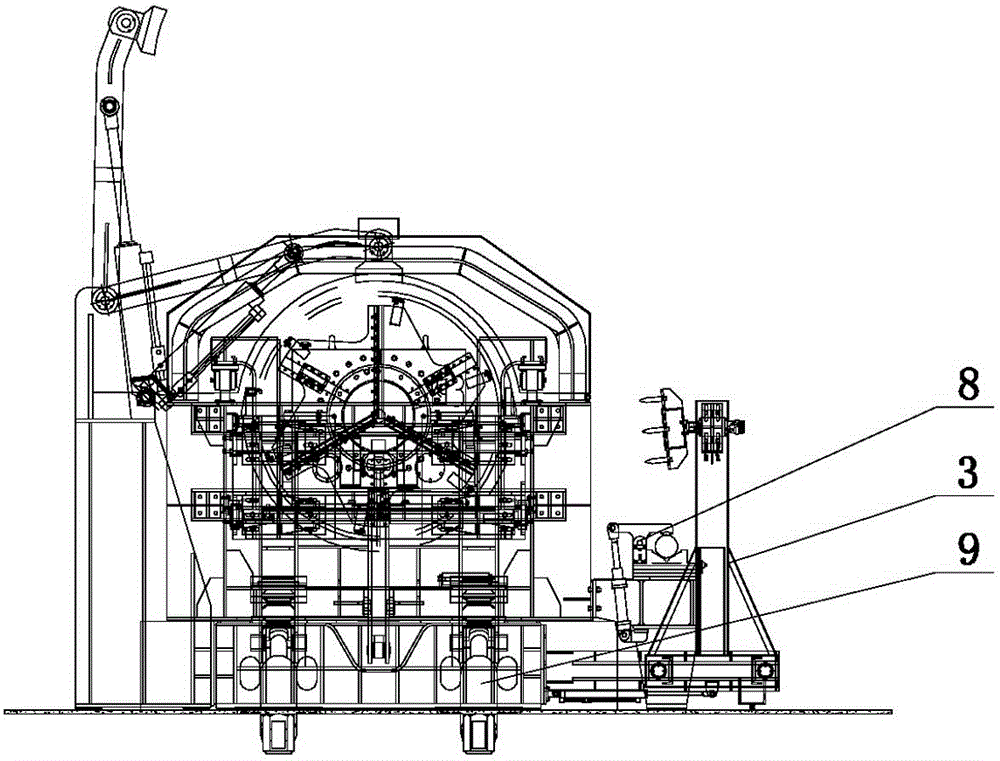

[0028] The present invention comprises a machine base 9, a driving device 7 is arranged on the top of the machine base 9, a cutter head 6 with an aluminum bag cleaning tool 5 is arranged on the driving device 7, and a tilting device 2 is arranged on the machine base 9 corresponding to the aluminum bag cleaning tool 5 The bottom of the machine base 9 is corresponding to the residue car 4 between the aluminum bag cleaning tool 5 and the tipping device 2, and it is characterized in that: the machine base 9 is located on the side of the driving device 7 and the aluminum bag cleaning tool 5. Aluminum suction tube cleaning machine 8; the cutter head 6 is provided with a knife rest 13, and the aluminum bag cleaning cutter 5 is fixedly connected with the knife rest 13 through bolts 14.

[0029] The surface of the cutter head 6 is provided with a groove, the groove is provided with an L-shaped knife seat 11, the L-shaped knife seat 11 is provided with an L-shaped knife rest 13, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com