GH4738 alloy fine-grain blank manufacturing method for supercritical power station steam turbine blade

A steam turbine blade and supercritical technology, which is applied in the field of preparation of GH4738 alloy fine-grain blanks for supercritical power station steam turbine blades, can solve the problems of cracking of forgings, uneven temperature field, uneven distribution of grains, etc. Shape, high degree of macroscopic uniformity, and high degree of microstructure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

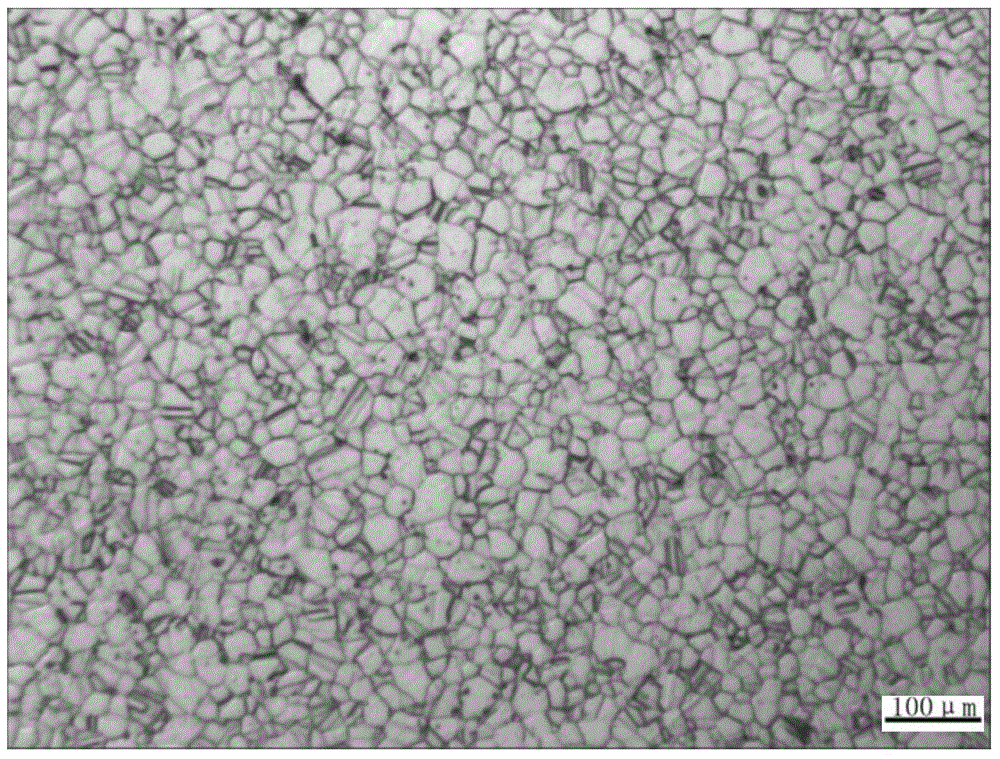

Embodiment 1

[0031] A method for preparing a GH4738 alloy fine-grain billet for an ultra-supercritical power station steam turbine blade is as follows:

[0032] (1). Cover the GH4738 alloy ingot after homogenization treatment:

[0033] Put the homogenized Φ200mm ingot into the 08F steel ladle after blowing sand and coating the surface with glass lubricant, and form a prefabricated extrusion billet after welding;

[0034] (2). Prefabricated extrusion heating:

[0035] The prefabricated extruded billet is heated to 1060°C and held for 320 minutes, and the preformed billet heat preservation time is calculated according to the following formula:

[0036] t 保温时间 =D 预制坯直径 (200mm)×1.6min / mm=320min

[0037] In the formula: t 保温时间 = holding time of ingot, min; d 铸锭直径 = ingot diameter, mm;

[0038] (3) Mold heating:

[0039] Heat the mold to 500°C and keep it warm for 6 hours; and apply graphite lubricant evenly on the inner surface of the mold cavity before hot extrusion;

[0040](4) Put t...

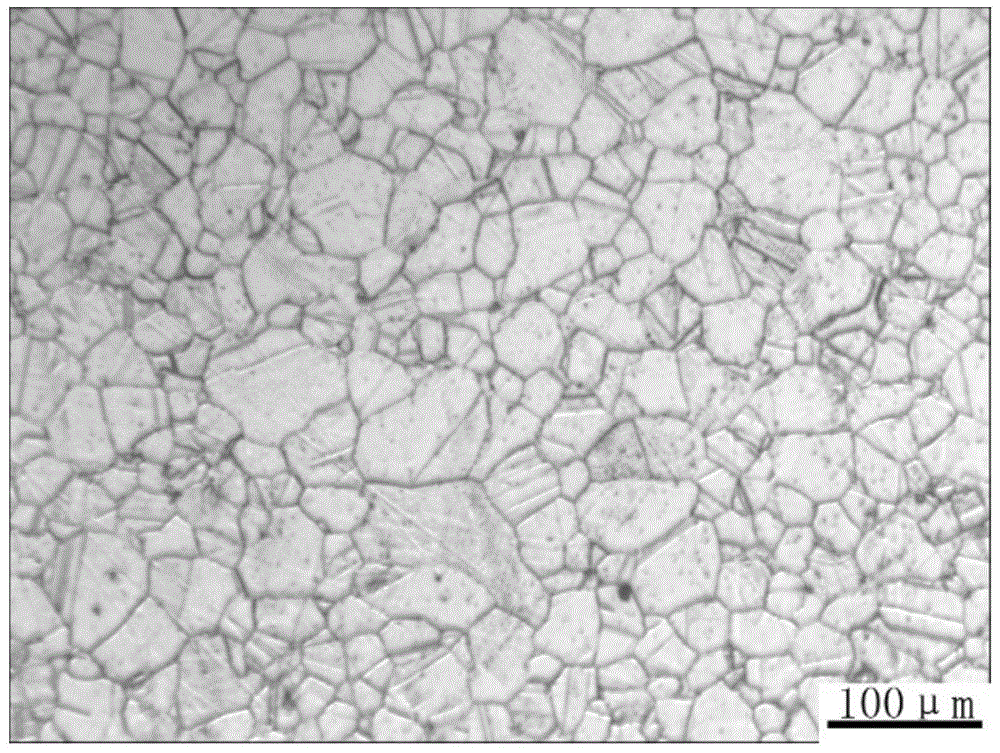

Embodiment 2

[0043] A kind of GH4738 nickel-based superalloy large ingot type blanking method steps are as follows:

[0044] (1). Cover the GH4738 alloy ingot after homogenization treatment:

[0045] Put the homogenized Φ200mm ingot into the 08F steel ladle after blowing sand and coating the surface with glass lubricant, and form a prefabricated extrusion billet after welding;

[0046] (2). Prefabricated extrusion heating:

[0047] The prefabricated extruded billet is heated to 1090°C for heat preservation, and the heat preservation time of the preform is calculated according to the following formula:

[0048] t 保温时间 =D 预制坯直径 (200mm)×1.6min / mm=320min

[0049] In the formula: t 保温时间 = holding time of ingot, min; d 铸锭直径 = ingot diameter, mm;

[0050] (3) Mold heating:

[0051] Heat the mold to 500°C and keep it warm for 6 hours; and apply graphite lubricant evenly on the inner surface of the mold cavity before hot extrusion;

[0052] (4) Put the prefabricated extruded billet into th...

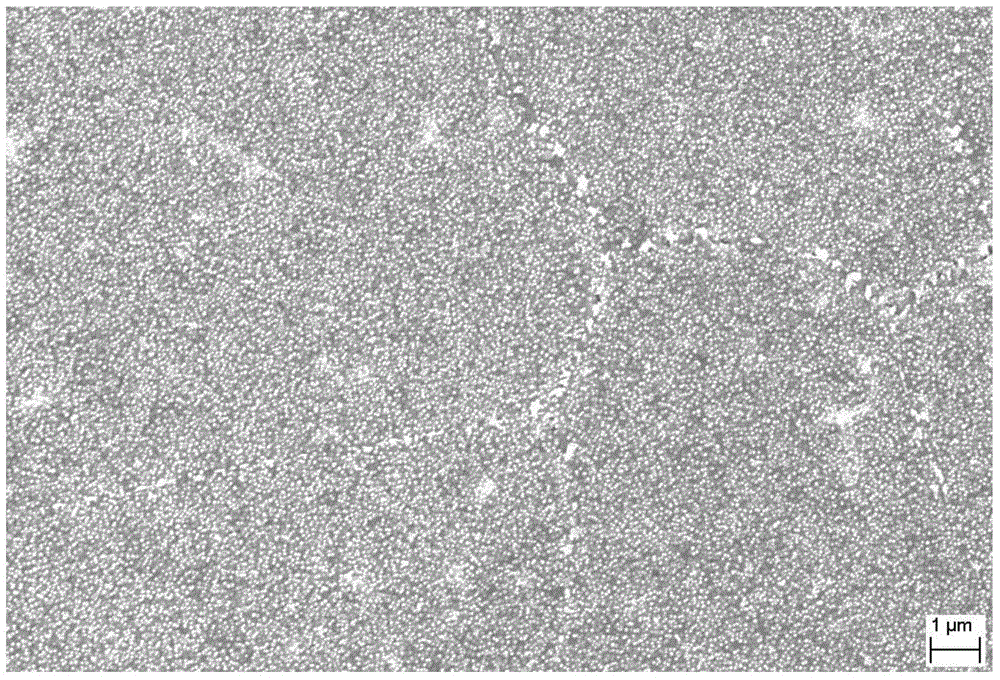

Embodiment 3

[0055] A method for preparing a GH4738 alloy fine-grain billet for an ultra-supercritical power station steam turbine blade is as follows:

[0056] (1). Cover the GH4738 alloy ingot after homogenization treatment:

[0057] Put the homogenized Φ200mm ingot into the 08F steel ladle after blowing sand and coating the surface with glass lubricant, and form a prefabricated extrusion billet after welding;

[0058] (2). Prefabricated extrusion heating:

[0059] The prefabricated extruded billet is heated to 1150°C for heat preservation, and the heat preservation time of the preform is calculated according to the following formula:

[0060] t 保温时间 =D 预制坯直径 ×1.6min / mm=320min

[0061] In the formula: t 保温时间 = holding time of ingot, min; d 铸锭直径 = ingot diameter, mm;

[0062] (3) Mold heating:

[0063] Heat the mold to 500°C and keep it warm for 6 hours; and apply graphite lubricant evenly on the inner surface of the mold cavity before hot extrusion;

[0064] (4) Put the prefabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com