Method for operating on-off valves

A technology of switching valves and closing control, which is applied to the direction of valves, valve devices, and functional valve types used for ventilation, and can solve the problems of introducing additional costs for current sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] figure 1 A fuel tank ventilation system of a motor vehicle is schematically shown. The motor vehicle has an engine 7 , the combustion air of which is supplied via an intake duct 6 . Other components of the engine (injection system, etc.) are not illustrated here. The vehicle further has a fuel tank 1 from which fuel vapors are supplied via a line 2 to an activated carbon filter 3 and are adsorbed by said activated carbon filter 3 . These hydrocarbons adsorbed in the filter are introduced via line 5 into the intake duct 6 of the engine 7 by opening the tank vent valve 4 to be flushed at certain intervals, to be supplied with the combustion air to the combustion process of the engine. A pressure sensor 8 is arranged in the region of the intake manifold 6 , wherein the pressure prevailing in the intake manifold can be measured by means of the pressure sensor 8 .

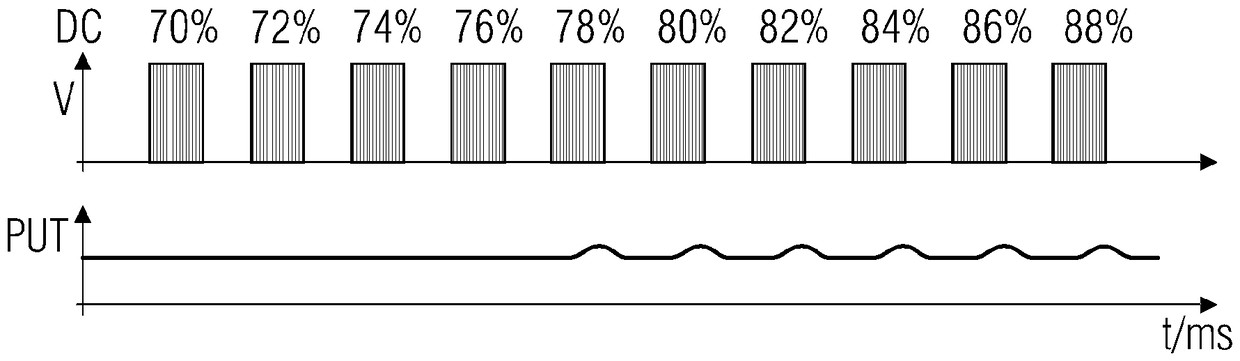

[0034] The system further has a control device 9 which can be part of the engine controller. The control d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com