Adjustable arrangement for transforming a planar support, cassette, unit and machine equipped with same

一种加工装置、加工工具的技术,应用在金属加工、机械加工/变形、容器等方向,能够解决不可能调节第一轴承和第三轴承第二轴承和第四轴承水平程度等问题,达到小机械加工精度、精确度确实优良、时间减少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

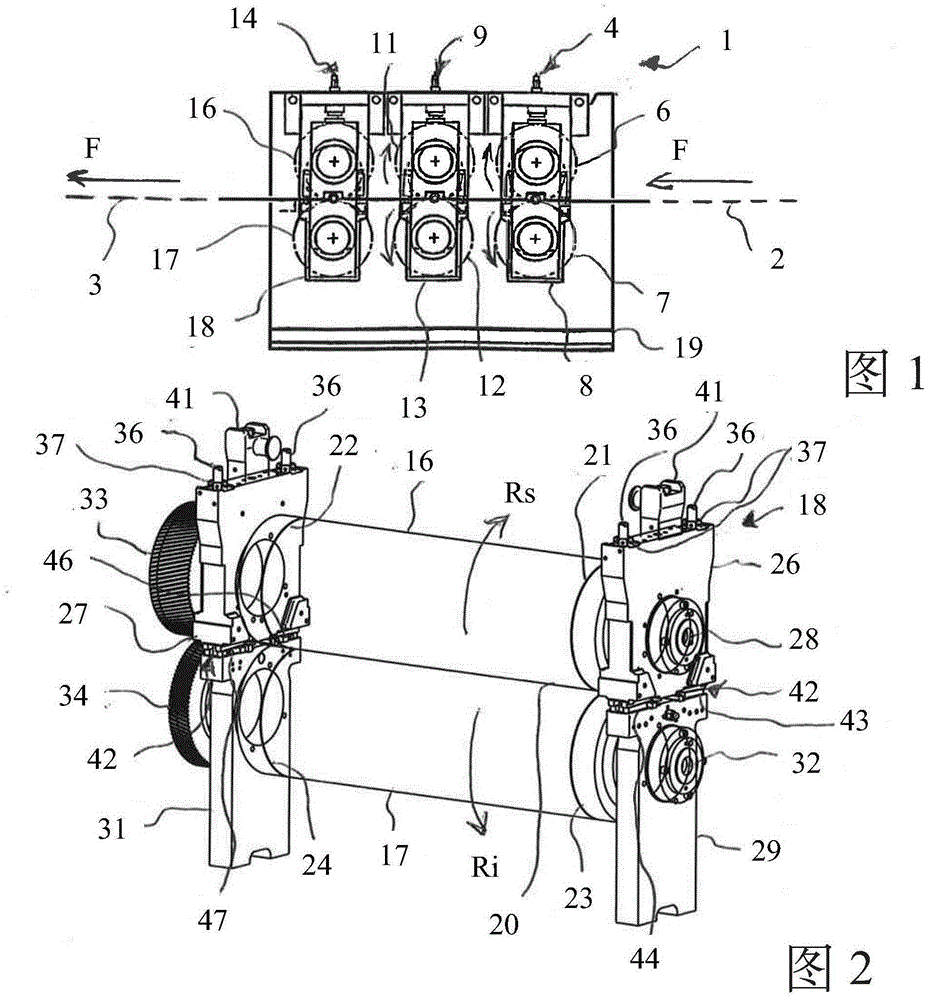

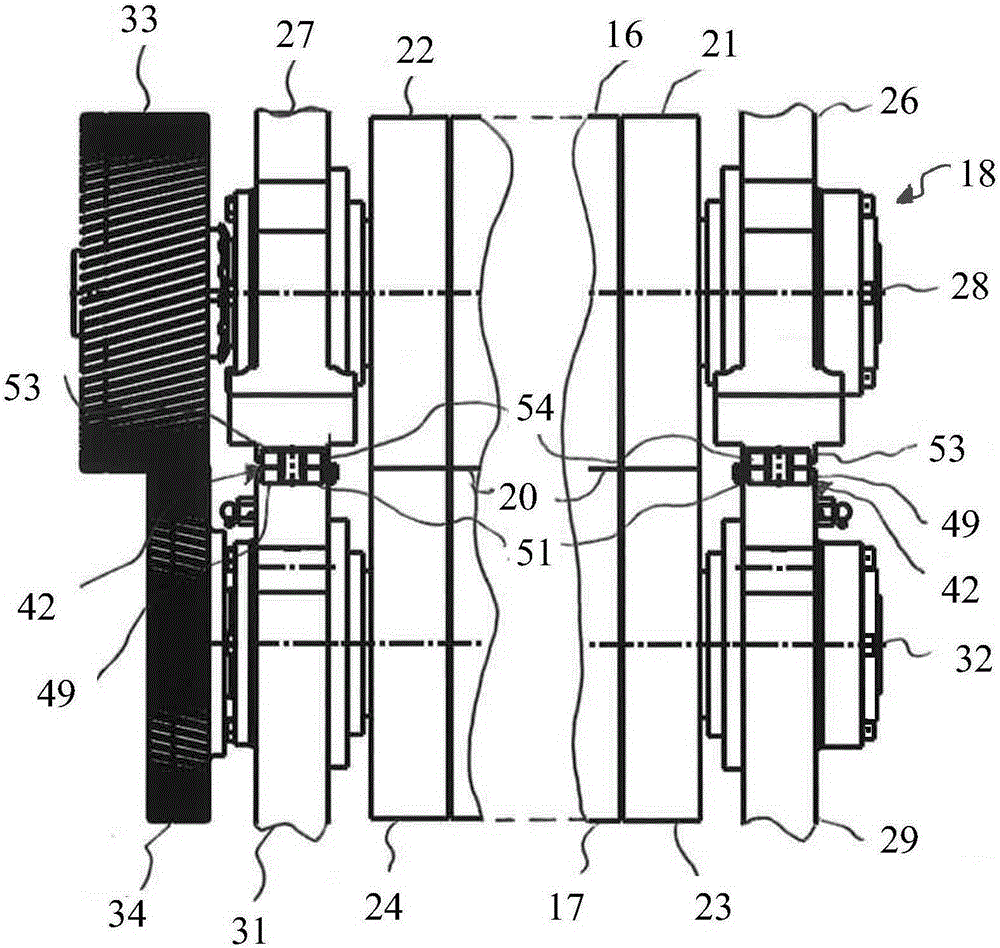

[0029] The machined material or flat substrate used to produce the packaging (not shown), in this case a continuous web (eg flat cardboard). Such as figure 1 As shown, the machine comprises a substrate processing unit 1 for processing a web 2 . The feeding or unwinding direction of the web 2 ( figure 1 The arrow F) in is along the longitudinal direction, which indicates the upstream and downstream directions of the processing unit 1 . The front and rear positions are defined with respect to the lateral direction as the side of the driver or operator and the side opposite the driver or operator, respectively.

[0030] The machine may have a web unwinder, units such as printing assemblies, means for controlling the printing quality and documentation, web guiding means, and other units upstream of the processing unit 1 .

[0031] Processing unit 1 is a unit for embossing, hemming and cutting. The web 2 reaches the unit 1 at a constant speed through the upstream transverse sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com