Slide fastener

A technology for zippers and zipper tapes, which is applied in the field of zippers for left and right zipper strings, and can solve problems such as being stuck on the outer wall side of the flange, unspecified distances between dimensions, and chain teeth coming out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

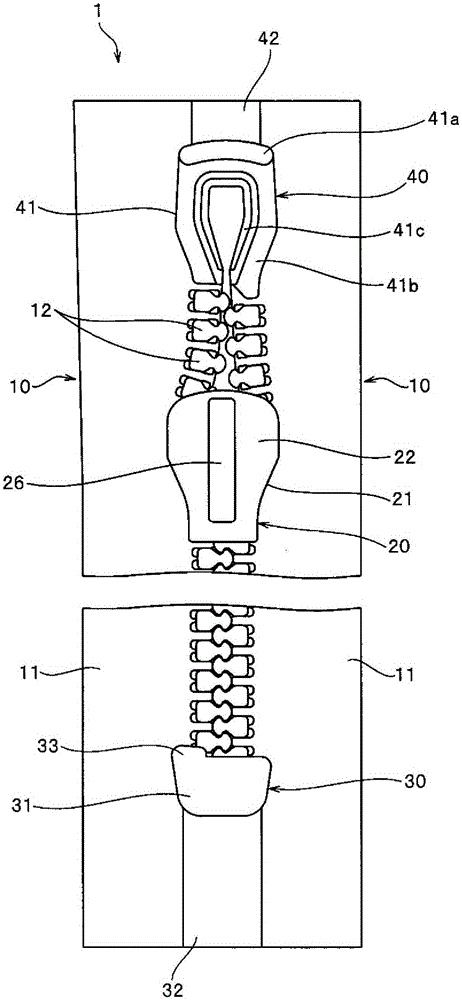

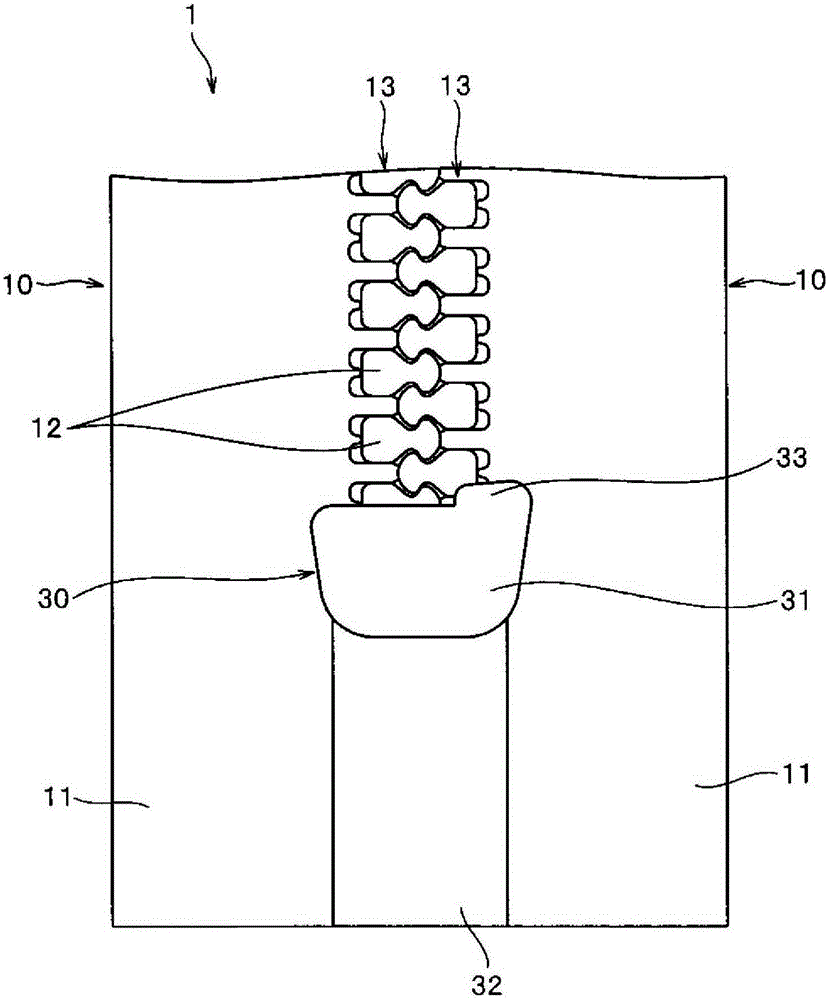

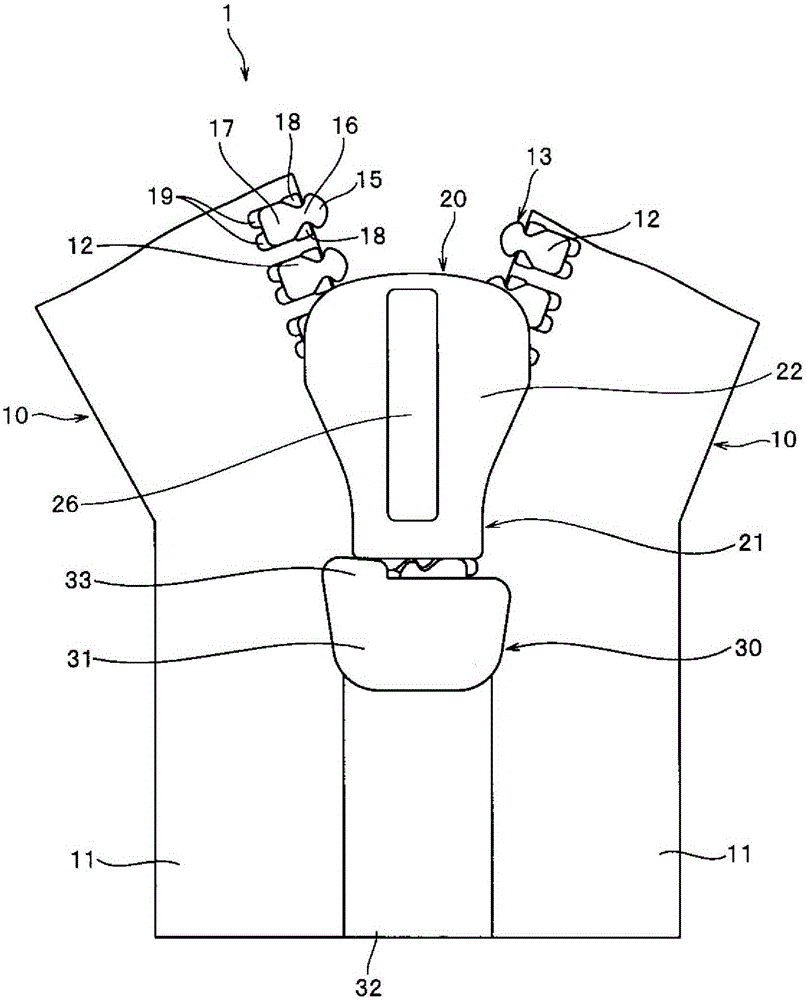

[0092] figure 1 It is a plan view which shows the slide fastener of this Example 1. figure 2 It is an enlarged bottom view showing the first stopper of the zipper. image 3 It is an enlarged plan view showing a state in which the slider is brought into contact with the first stopper in the slide fastener.

[0093] In addition, as mentioned above, in the slide fastener, the front-rear direction refers to the tape length direction of the fastener tape, and is the same linear direction as the slide direction in which the slider slides. In particular, the direction in which the slider is slid to mesh the left and right element rows is defined as the front, and the direction in which the slider is slid to release the meshing of the element rows is defined as the rear.

[0094] In addition, the left-right direction means the tape width direction of a fastener tape, and is a direction parallel to the tape surface of a fastener tape and orthogonal to a tape length direction. Espe...

Embodiment 2

[0156] Figure 6 It is a plan view which shows the slide fastener of this Example 2. Figure 7It is an enlarged perspective view showing fastener elements of the slide fastener. Figure 8 is a bottom view showing the first stop of the zipper. In addition, due to Figure 8 It is a bottom view, and the left and right directions are reversed.

[0157] The slide fastener 2 of the present embodiment 2 is constituted as a waterproof slide fastener provided with a waterproof structure in which liquid such as water does not leak from the tape front side to the tape back side (or from the tape back side to the tape front side) when the slide fastener 2 is closed. . In addition, since the slide fastener 2 of this Example 2 is lower in waterproofness than the waterproof slide fastener 1 in the said Example 1, it may also be called a waterproof slide fastener.

[0158] The waterproof zipper 2 of the present embodiment 2 has: a pair of left and right zipper stringers 50 formed by inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com