Evaluation method for flame burning condition and stability

A technology of flame combustion and evaluation method, which is applied in the field of energy and environment, and can solve the problems of lower boiler thermal efficiency, lower combustion stability, and deviation of combustion flame conditions, etc., and achieve the effects of less interference, high repeatability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

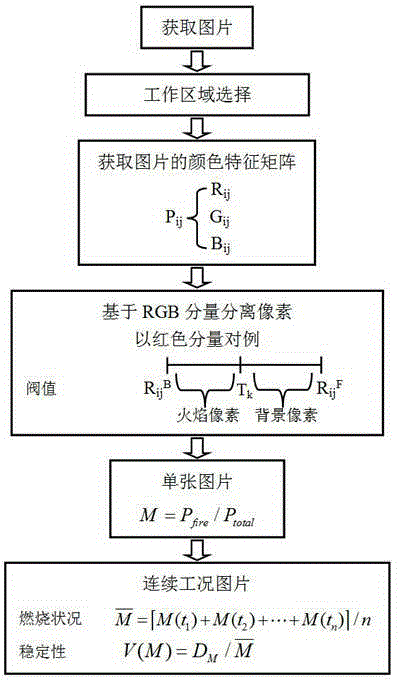

[0030] The evaluation method of flame combustion status and stability described in this embodiment, taking red as an example, specifically includes the following steps:

[0031] Step 1) obtain the image of flame burning;

[0032] Step 2) Yes figure 2 Perform processing and intercept the area to be evaluated;

[0033] Step 3) Import the processed picture into Matlab software to obtain the brightness feature matrix R about red ij ;

[0034] Step 4) Select red as the evaluation color, and use an iterative method to determine the optimal threshold T for segmenting the area where the flame is located k =215;

[0035] Step 5) combine each pixel in the brightness feature matrix of the selected color with the threshold T k is compared when R ij ≥T k When R ij k When , it is considered that there is no flame in the area where the pixel is located, and the number of flame pixels obtained is P fire =93829, the total number of pixels is P total =192500. The flame combustion st...

Embodiment 2

[0045] The evaluation method of flame combustion status and stability described in this embodiment, taking green as an example, specifically includes the following steps:

[0046] Step 1) obtain the image of flame burning;

[0047] Step 2) processing the image, intercepting the area to be evaluated;

[0048] Step 3) import the processed picture into Matlab software to obtain the brightness feature matrix G about green ij ;

[0049] Step 4) Select green as the evaluation color, and use an iterative method to determine the optimal threshold T for segmenting the area where the flame is located k =180;

[0050] Step 5) combine each pixel in the brightness feature matrix of the selected color with the threshold T k For comparison, when G ij ≥T k When G ij k When , it is considered that there is no flame in the area where the pixel is located, and the number of flame pixels obtained is P fire =95963, the total number of pixels is P total =192500. The flame combustion statu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com