Two-stage temperature control system for semiconductor laser

A temperature control system and temperature control technology, applied in the direction of semiconductor lasers, temperature control, control/regulation systems, etc., can solve problems such as unfavorable control system accuracy, and achieve the effect of extending the working environment, eliminating influence, and increasing temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

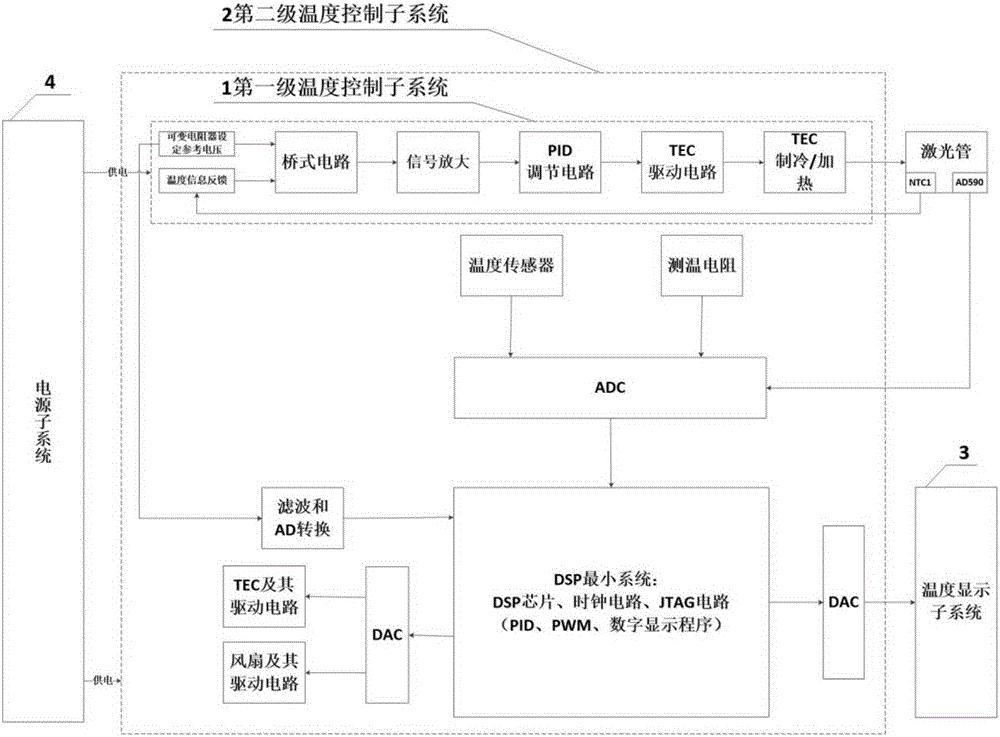

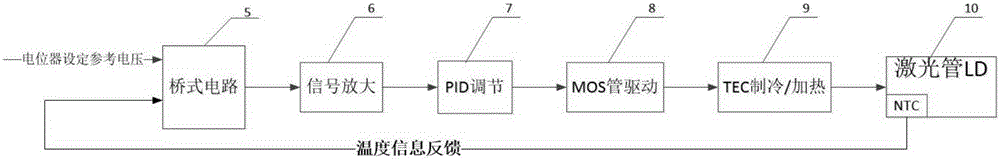

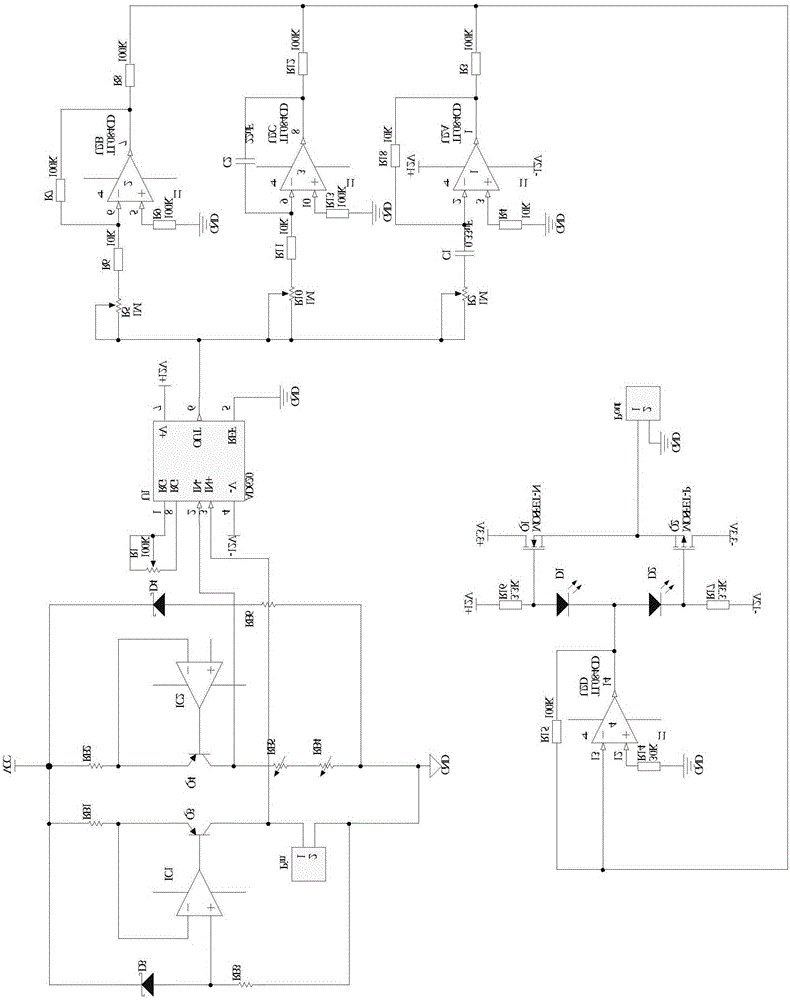

[0025] like figure 1 As shown, the present invention is a two-level temperature control system for semiconductor lasers, including a first-level temperature control subsystem 1 , a second-level temperature control subsystem 2 , a temperature display subsystem 3 and a power supply subsystem 4 . The first-level temperature control subsystem 1 controls the temperature of the semiconductor laser tube by driving TEC cooling / heating through analog PID adjustment; the second-level temperature control subsystem drives TEC and fan control temperature control through digital PID adjustment and PWM modulation The temperature of the system is stable; the display subsystem displays the set temperature and current temperature of the first-level and second-level temperature control subsystems in real time; the power supply subsystem provides power for circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com