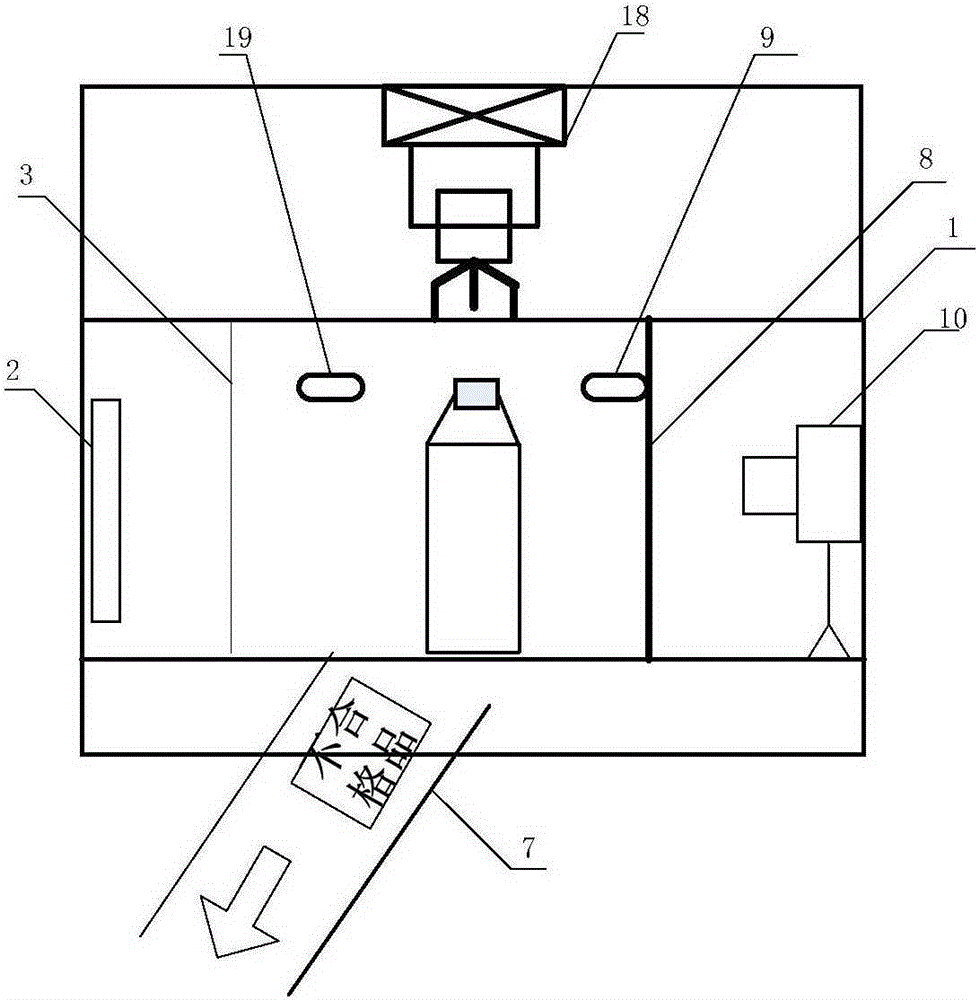

Image processing-based bottled liquid impurity detection system and detection method thereof

A technology for bottled liquids and detection systems, applied in image data processing, image enhancement, image analysis, etc., can solve problems such as increasing the amount of data, separation of images and backgrounds, etc., to reduce complexity, improve product quality and supply speed, Easy-to-see effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] The present invention can use the upper computer software to display the camera collection information and processing information in real time, and can save statistical files, calculate the overall qualification rate of the produced products; then design the image processing algorithm and the overall flow of the system; also design a set of suitable The pipeline hardware platform, including the overall selection and structure of the hardware and the reasonable design of the light source, provides a clear and suitable image for the post-image processing and recognition; and uses the FPGA to collect the infrared pair tube signal to realize the detection and automatic capture of the moving bottle. , The software exchanges information with FPGA through the RS232 serial port, and transmits the processing results to the FPGA through the serial port to complete t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com