Fine-tunable microscopic inspection device for repairing micro-defects of large-aperture curved optical components

A technology for optical components and microscopic inspection, which is applied in optical testing of flaws/defects, measuring devices, and material analysis through optical means. It can solve problems such as poor positioning accuracy, achieve high precision, ensure stability, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

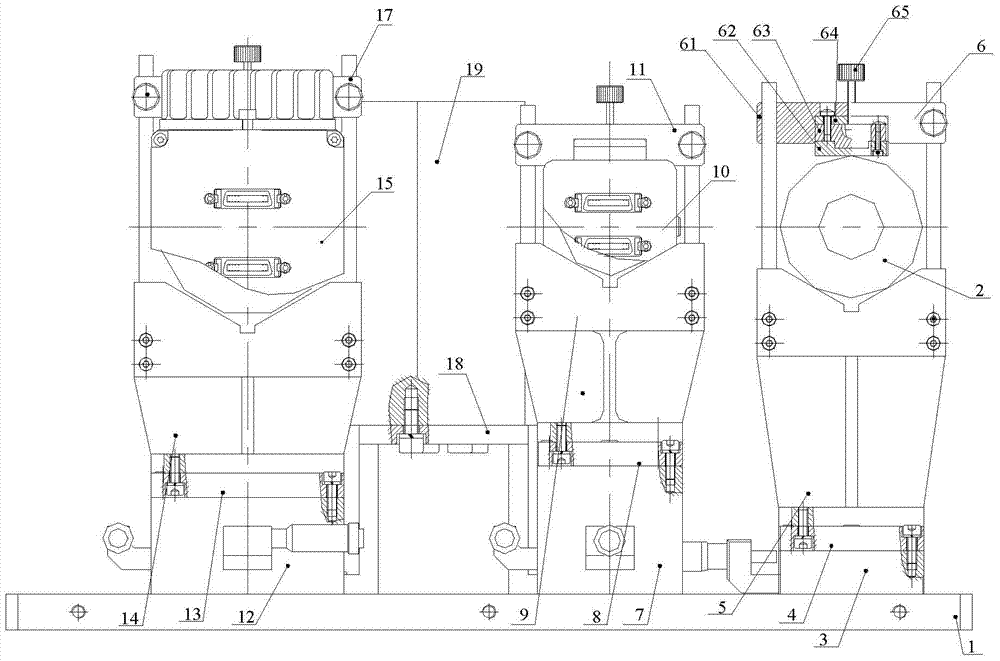

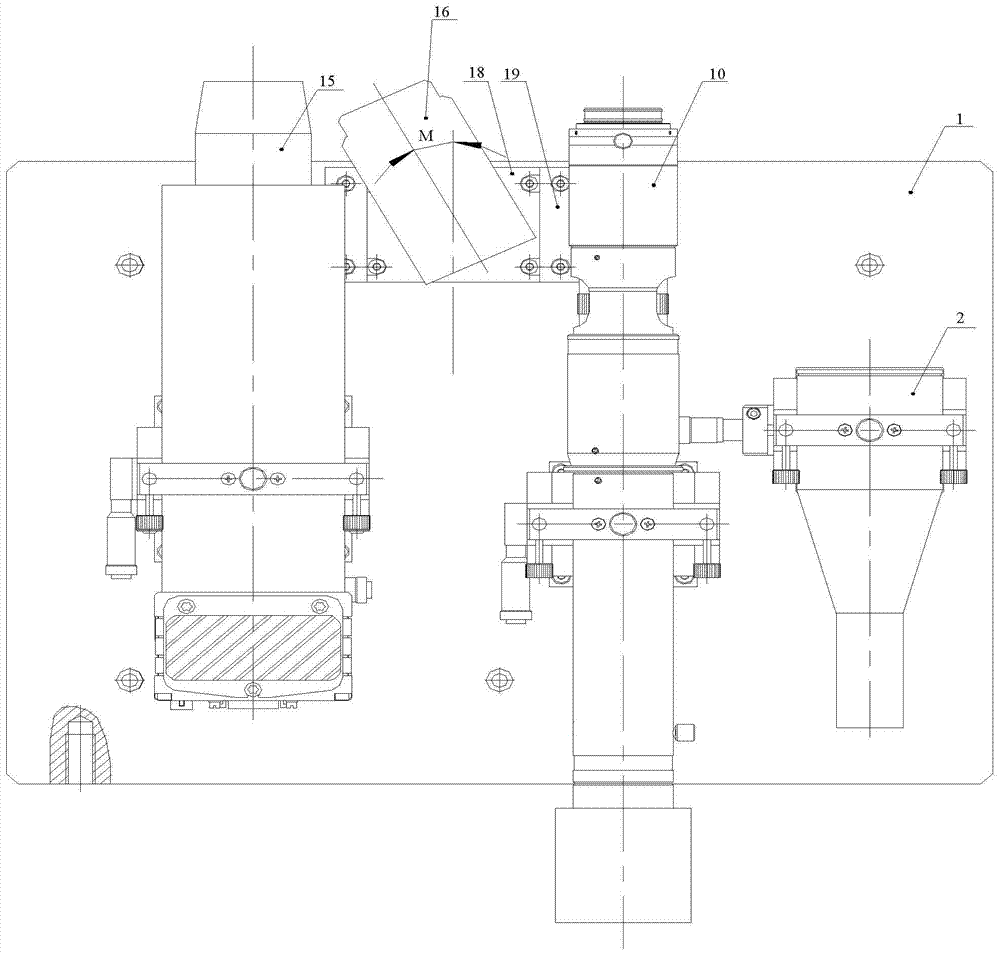

[0026] Specific implementation mode one, combination figure 1 with figure 2 This embodiment will be described. The fine-tunable micro-detection device for repairing micro-defects of large-diameter curved optical elements according to this embodiment includes a dark field detection unit, a bright field monitoring unit, a spectral confocal precision ranging unit and a micro system Mounting board 1;

[0027] The spectral confocal precise ranging unit includes a spectral confocal range finder 2, an optical X-axis precision fine-tuning sliding table 3, a ranging transition plate 4, a ranging V-block fixture 5, and a ranging clamping device 6;

[0028] The bottom surface of the optical X-axis precision fine-tuning slide 3 is fixed on the upper surface of the micro system mounting board 1, and the optical X-axis precision fine-tuning slide 3 is fixedly connected to the lower surface of the distance measuring transition plate 4 by screws, and the upper surface of the distance measuring tra...

specific Embodiment approach 2

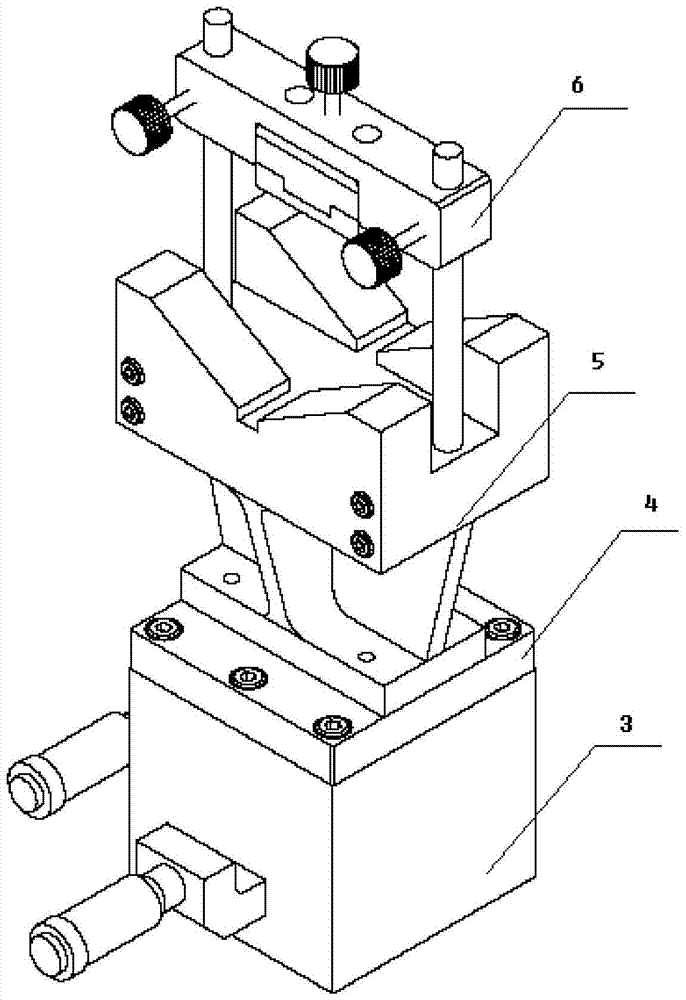

[0043] Embodiment 2 This embodiment is a further description of the fine-tunable microscopic inspection device for repairing micro-defects of large-diameter curved optical elements described in Embodiment 1. The distance measuring clamping device 6, the bright field clamping device 11 The structure of the dark field clamping device 17 is the same, and the distance measuring clamping device 6 is taken as an example for description. The distance measuring clamping device 6 includes a pre-tightening pressing block 61, a pre-tightening pressing piece 62, a pre-tightening base 63, Pre-tightening the cover 64 and adjusting the flat head screw 65;

[0044] The upper surface of the pre-compression block 61 is provided with two circular through holes. The circular through-holes are provided at both ends of the pre-compression block 61 for the two cylinders to pass through. A gap is provided between the blocks 61, and two clamping screws are provided on the sides of the two circular throug...

specific Embodiment approach 3

[0046] Embodiment 3 This embodiment is a further description of the fine-tunable microscopic inspection device for repairing micro-defects of the aperture curved optical element described in the first embodiment, and it also includes a transverse fixing plate 18 and a longitudinal fixing plate 19. The horizontal fixing plate 18 is arranged horizontally, and the lower end of the horizontal fixing plate 18 is provided with mounting feet, and the mounting feet fix the horizontal fixing plate 18 on the upper surface of the micro system mounting board 1 by screws, and the vertical fixing plate 19 is arranged vertically. The bottom edge of the vertical fixing plate 19 is fixedly connected to the upper surface of the horizontal fixing plate 18 by screws. The dark field light source 16 is fixed on the horizontal fixing plate 18 and located in the area enclosed by the horizontal fixing plate 18 and the vertical fixing plate 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com