Drilling fluidic element detection device

A detection device and technology of fluidic components, applied in the field of oil drilling, can solve problems such as unfavorable instrument measurement, small size of fluidic components, complex internal structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

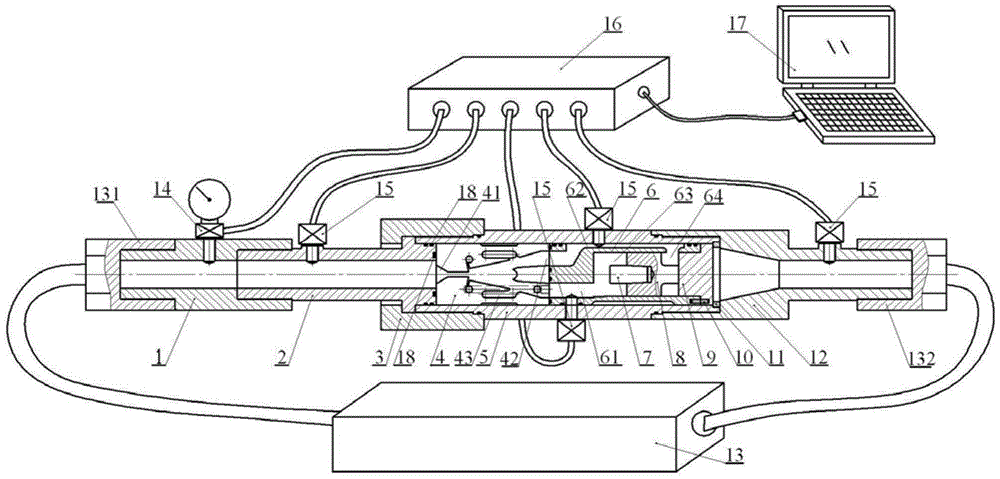

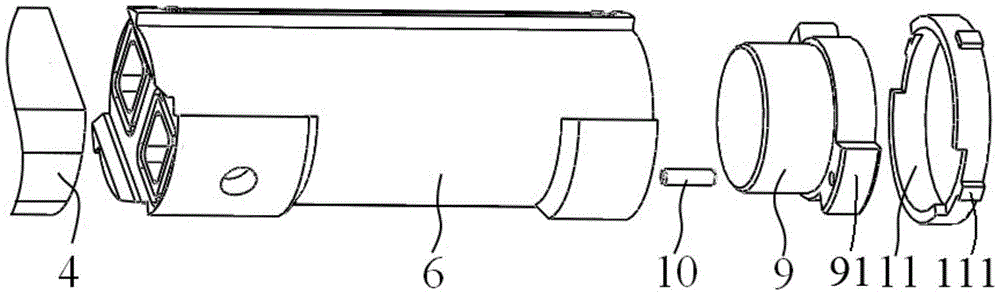

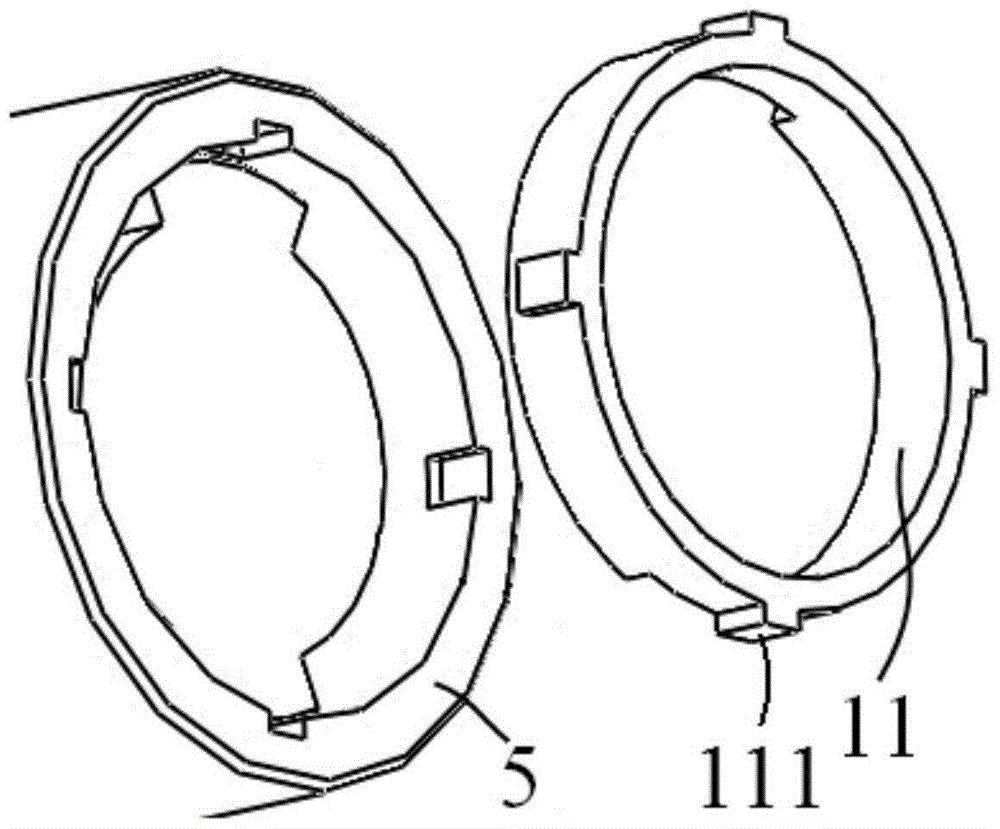

[0024] The present invention will be specifically described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the jet element detection device for drilling of the present invention includes: a flowmeter joint 1, an upper gland 2, an outer pipe 5, an outer pipe joint 12, a pump 13, a data collector 16 and a computer 17; the outer pipe 5 The interior is sequentially equipped with a fluidic element 4, a hydraulic cylinder 6, a cylinder head 9 and a positioning spacer 11 from top to bottom; the output pipeline of the pump 13 is fixedly connected to the upper inlet port of the flowmeter joint 1, and the lower part of the flowmeter joint 1 The outlet end is fixedly connected to the top inlet end of the upper gland 2, and the lower outlet end of the upper gland 2 is inserted into the top inlet end of the outer tube 5 and fixedly connected.

[0025] Inside the outer tube 5, the outlet end of the lower part of the upper gland 2 is tightly pressed on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com