Huge piezoresistive property-based silicon nanowire pressure sensor and packaging structure thereof

A pressure sensor and silicon nanowire technology, applied in the field of micro-nano electromechanical system sensor design, can solve the problems of damaged sensor chip, only about kilohertz, and small resistance gauge coefficient of silicon piezoresistor, so as to eliminate parasitic latch effect , Reducing mechanical stress, and small short groove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

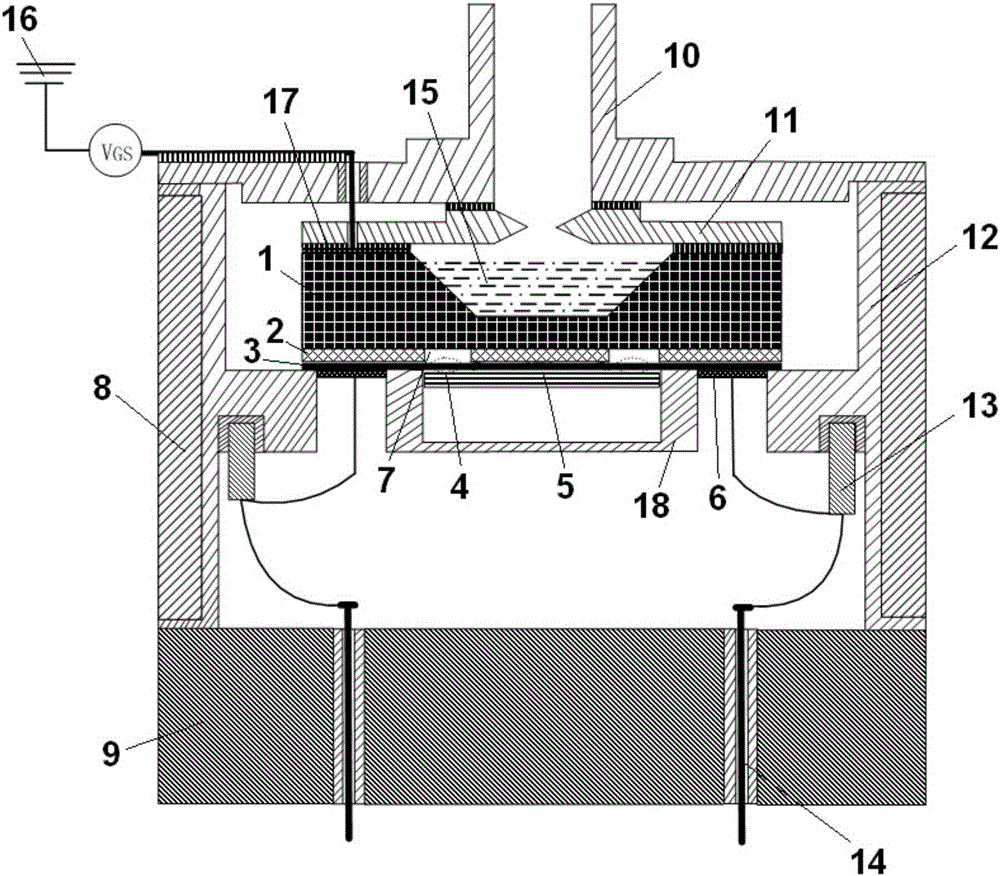

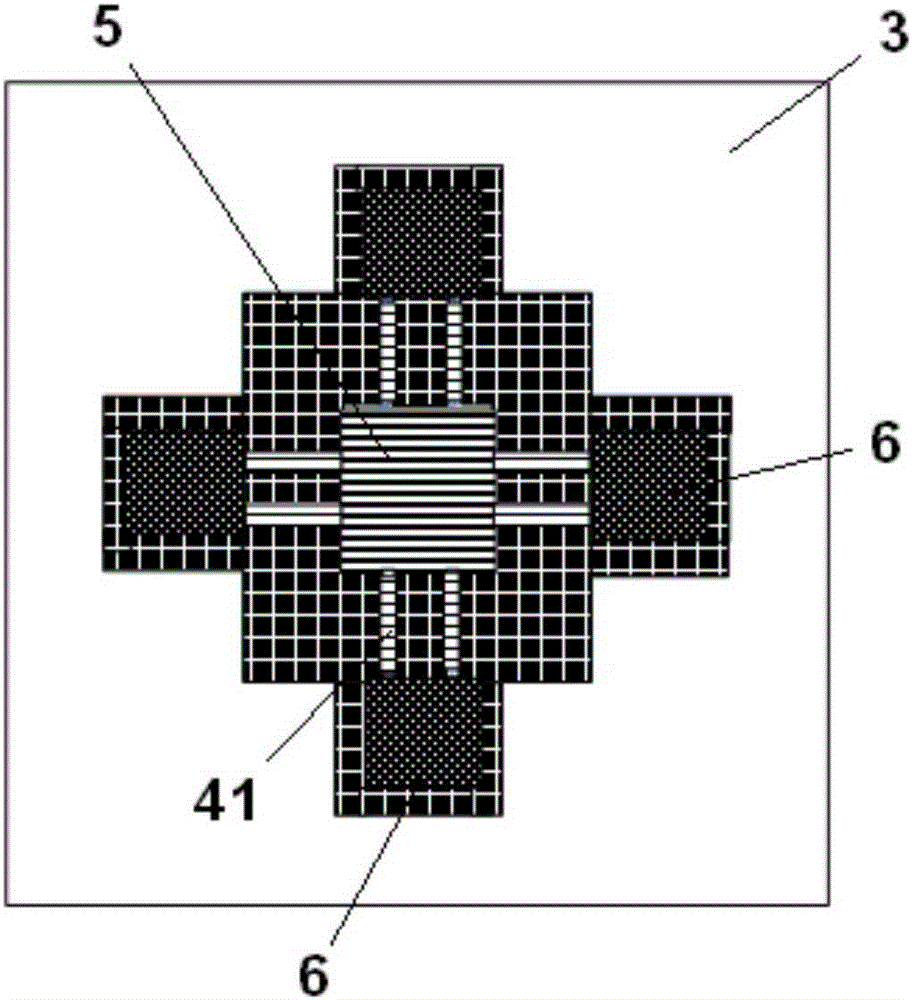

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

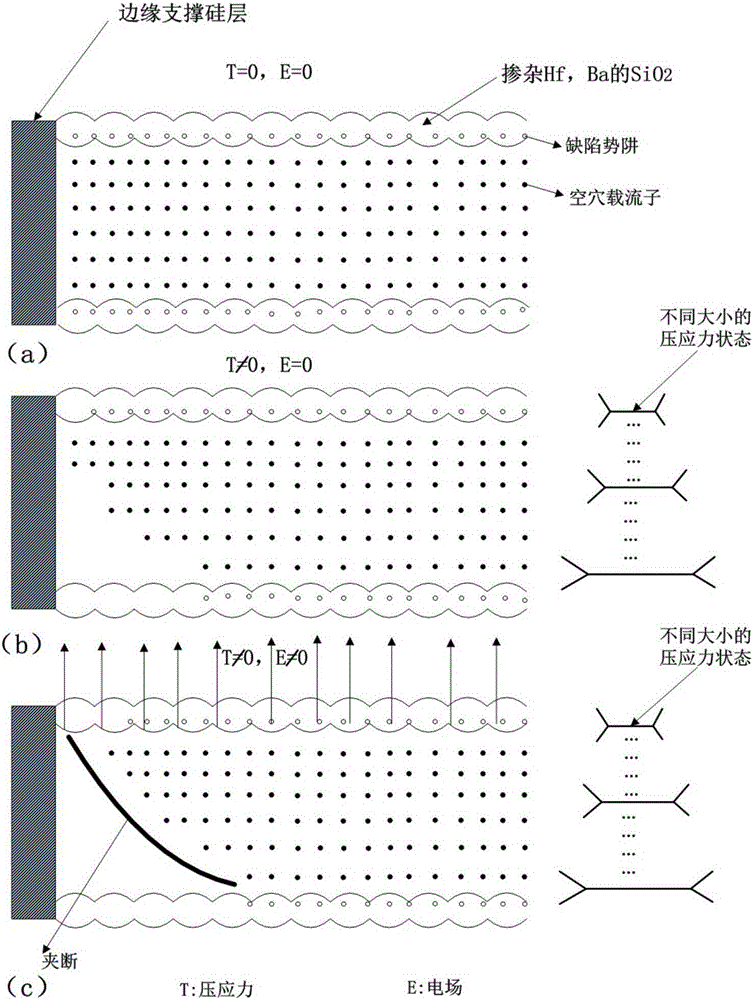

[0039] Such as figure 1 As shown in (a), the concentration of surface defect states at the interface can be increased by 2 orders of magnitude by doping Hf, Ba and other atoms at the interface between silicon nanowires and surface silicon dioxide, from the original 10 10 cm -2 Surface concentration increased to 10 12 cm -2 Above, due to the low doping concentration of silicon nanowires (generally 10 17 cm-2 (below), so the ratio of the concentration of defect states on the surface of silicon nanowires to the concentration of conductive holes on the nanowires is significantly increased, and the effect of defect states is also significantly enhanced. By optimizing the design of the silicon nanowire pressure sensor chip, different compressive stresses can be formed in the silicon nanowire. Such as figure 1 As shown in (b), under the action of the mechanical compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com