Circulating refueling pump for on-orbit refueling in space

A technology for filling pumps and spaces, applied in the components, pumps, pump devices and other directions of pumping devices for elastic fluids, can solve the problems of reduced pump life, leakage, frequent failures, etc., and achieve the effect of strengthening fixed friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

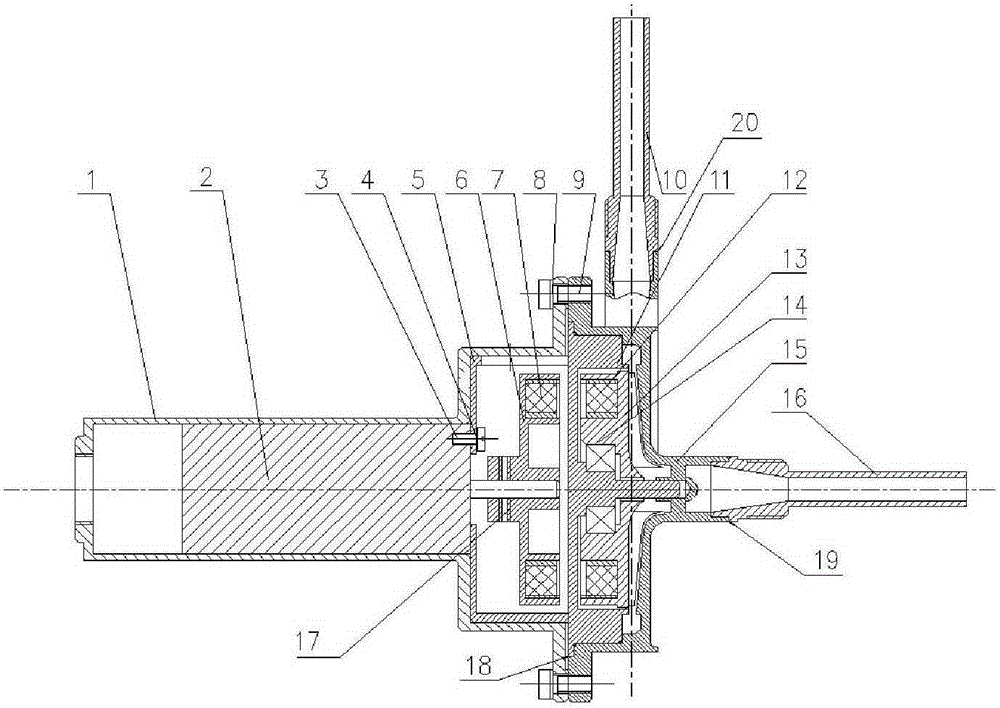

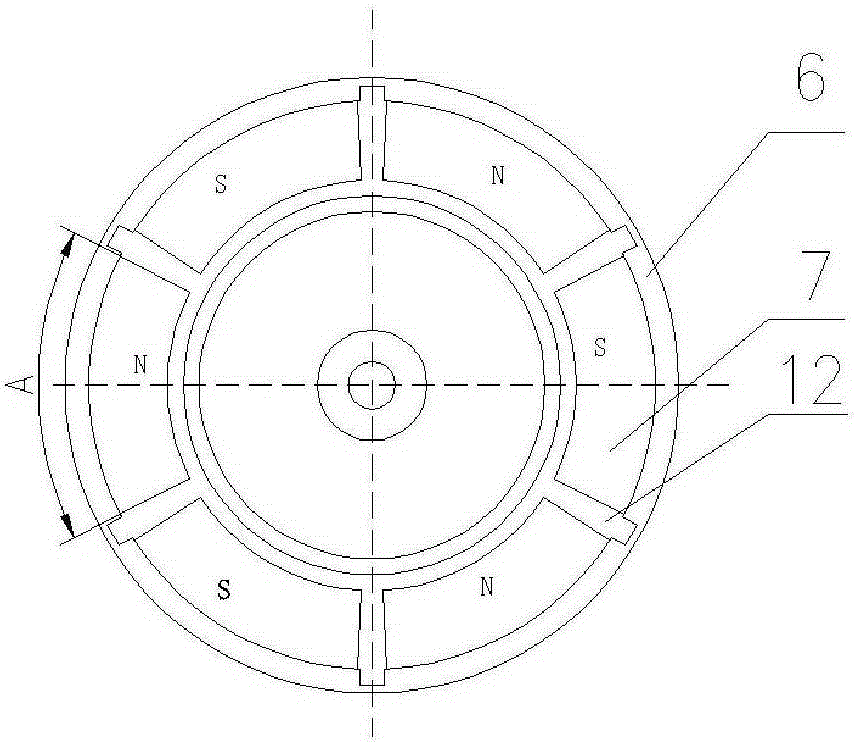

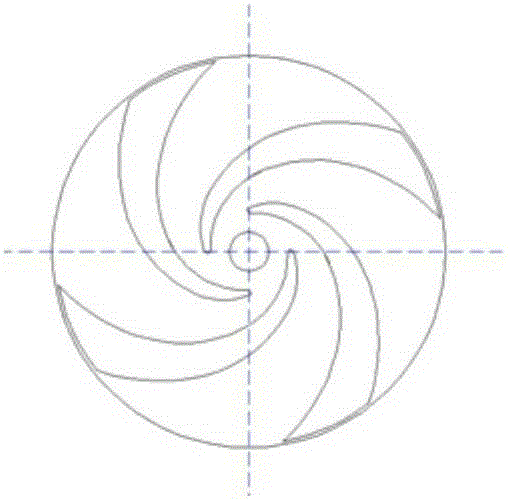

[0020] Such as figure 1 As shown, the present invention is a circulating filling pump for space on-rail filling, including a motor housing 1, a motor 2, a bolt A3, a gasket A4, a motor seat 5, a permanent magnet coupling 6, a permanent magnet 7, a gasket Sheet B8, bolt B9, outlet pipe 10, pump casing cover 11, clamp 12, impeller 13, bearing 14, pump casing 15, inlet pipe 16, hexagon socket bolt 17; motor 2 is fixed by motor base 5 with 3 bolts A3 On the motor casing 1, the motor casing 1 is in direct contact with the motor 2, which can quickly transfer the heat generated by the motor 2 to the motor casing 1, and transfer it to the pump casing 15 through the heat conduction of the motor casing 1, and finally use the pump casing 15 The internal fluid takes away the heat, so that the temperature of the motor 2 is kept constant, and the long-term operation of the motor 2 is ensured. The permanent magnet 7 cooperates with the clip 12 and the permanent magnet coupling 6 in an inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com