Series-connection hydraulic support for tunnel floor dinting

A technology of hydraulic support and roadway, which is used in pillars/supports, mining equipment, earth-moving drilling, etc., can solve the problems of narrow roof in rear space, difficult working face maintenance, height difference, etc., achieve good roof connection effect, and solve difficult moving , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

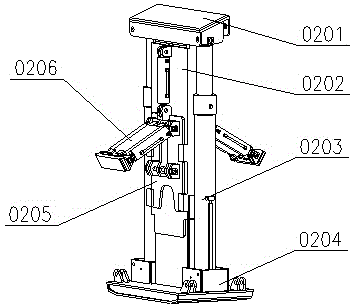

[0016] In specific implementation, such as figure 1 As shown, the present invention includes a front supporting frame 01, a rear anchoring frame 02, one end of the push-pull jack 03 is hinged to the base of the supporting frame 01, and the other end is hinged to the base of the anchoring frame 02 through a connector 04.

[0017] The front support frame 01 includes a top beam 0101, a telescopic stabilizing mechanism 0102, a base 0104 and a hydraulic column 0103, such as figure 2 As shown, the support frame 01 is placed under the nose of the conveyor and connected with the nose of the conveyor through a pin shaft, as image 3 As shown, it is used to support the suspended conveyor nose, and the support frame moves together with the scraper conveyor nose after connection; the top beam 0101 of the support frame is a right-angled trapezoidal structure, and a circle connecting the scraper conveyor nose is designed around it. hole, the support frame top beam 0101 is hinged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com