Gas drilling ground manifold connecting structure

A technology of gas drilling and connection structure, which is applied in the direction of earthwork drilling, wellbore flushing, wellbore/well components, etc. It can solve the problems of maintenance and replacement of drill bits, the effect of reverse circulation formation, and the inability to establish annular pressure, etc. , to prevent the disturbed collapse of the borehole wall, improve the drilling efficiency and save the gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

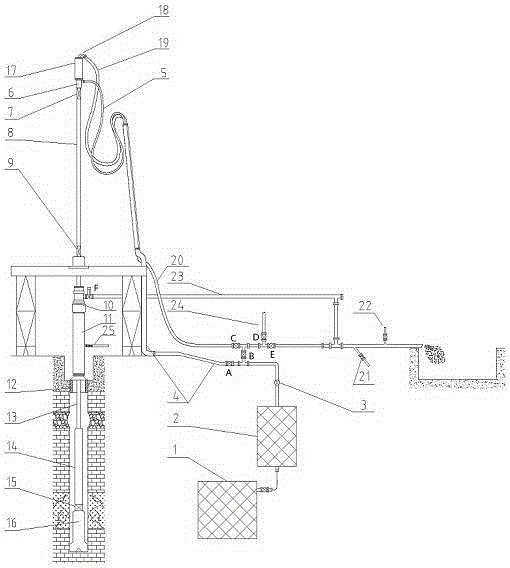

[0031] As a preferred embodiment of the present invention, it includes: gas injection unit 1, pressure relief unit 2, flow meter 3, ground gas injection manifold 4, high pressure gas injection hose 5, erosion resistant gooseneck 18, high pressure reaction Circulating sand discharge hose 19, ground reverse circulation sand discharge pipeline 20 and positive circulation gas drilling sand discharge pipeline 23,

[0032] Wherein: the gas injection unit 1 and the pressure relief unit 2 are connected by a high-pressure pipeline, the outlet of the pressure relief unit 2 is installed with the flow meter 3, the upstream of the flow meter 3 is connected to the pressure relief unit 2, the downstream is connected to the ground gas injection manifold 4, and the ground injection The trachea manifold 4 is connected with the high-pressure gas injection hose 5;

[0033] The outlet of the erosion-resistant gooseneck 18 is connected to a high-pressure reverse-circulation sand discharge hose 19, and t...

Embodiment 2

[0037] On the basis of the above-mentioned embodiment, a sampling nipple 21 and a dust suppression water nipple 22 are installed on the reverse circulation sand discharge pipeline 20 leading to the grit tank. The gas injection unit 1 provides high-pressure gas, including an air compressor and a booster. The left end of the four-way is connected to the ground reverse circulation sand discharge pipeline 20 through valve C, the right end is connected to a three-way through valve E, the upper end is connected to mud pump 24 through valve D, and the lower end is connected to ground gas injection manifold 4 and ground gas injection manifold 4 through valve B. A valve A is also provided between the high-pressure gas injection hose 5.

Embodiment 3

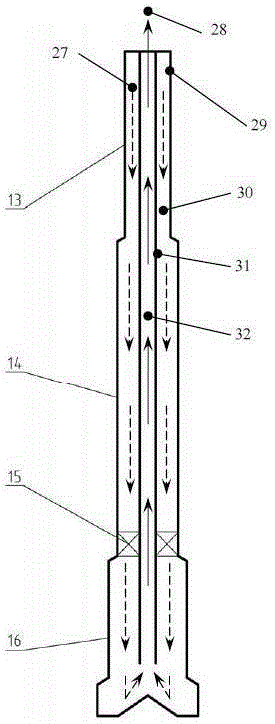

[0039] The specific application example of the present invention: a whole-well section self-priming reverse circulation gas drilling system consists of the following equipment and tools: gas injection unit 1, pressure relief unit 2, flow meter 3, surface gas injection manifold 4, high pressure gas injection Hose 5, gas distribution joint 6, double wall upper cock 7, double wall kelly 8, double wall lower cock 9, double wall drill pipe 10, double wall drill collar 11, annular check valve 12, reverse circulation rock breaking Tools (reverse circulation air hammer, reverse circulation cone bit or reverse circulation PDC bit) 13, double wall drill pipe 14, wellhead device 15, rotary blowout preventer 16, water tap (or top drive) 17, erosion resistant gooseneck 18. High-pressure reverse circulation sand discharge hose 19, ground reverse circulation sand discharge pipeline 20, sampling nipple 21, dust suppression water nipple 22, positive circulation gas drilling sand discharge pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com