A Confined Steel Tube Concrete Member

A technology of concrete-filled steel tube and concrete, which is applied to bridge parts, bridge construction, columns, etc., and can solve problems such as weak sections and reduced ductility of steel tube concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

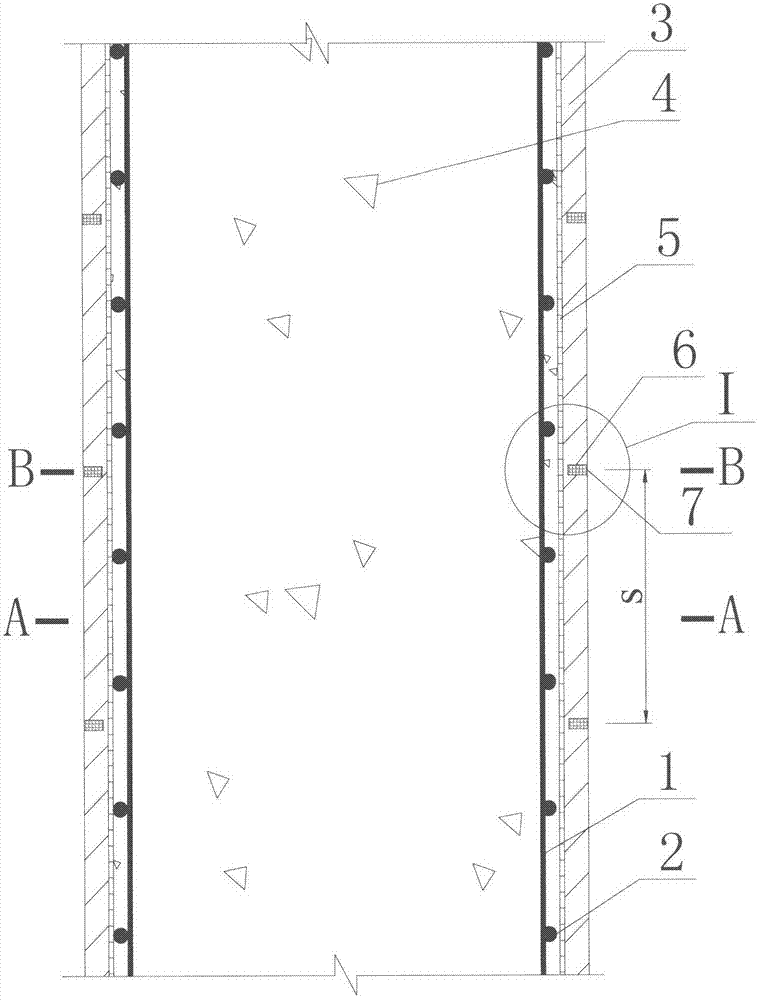

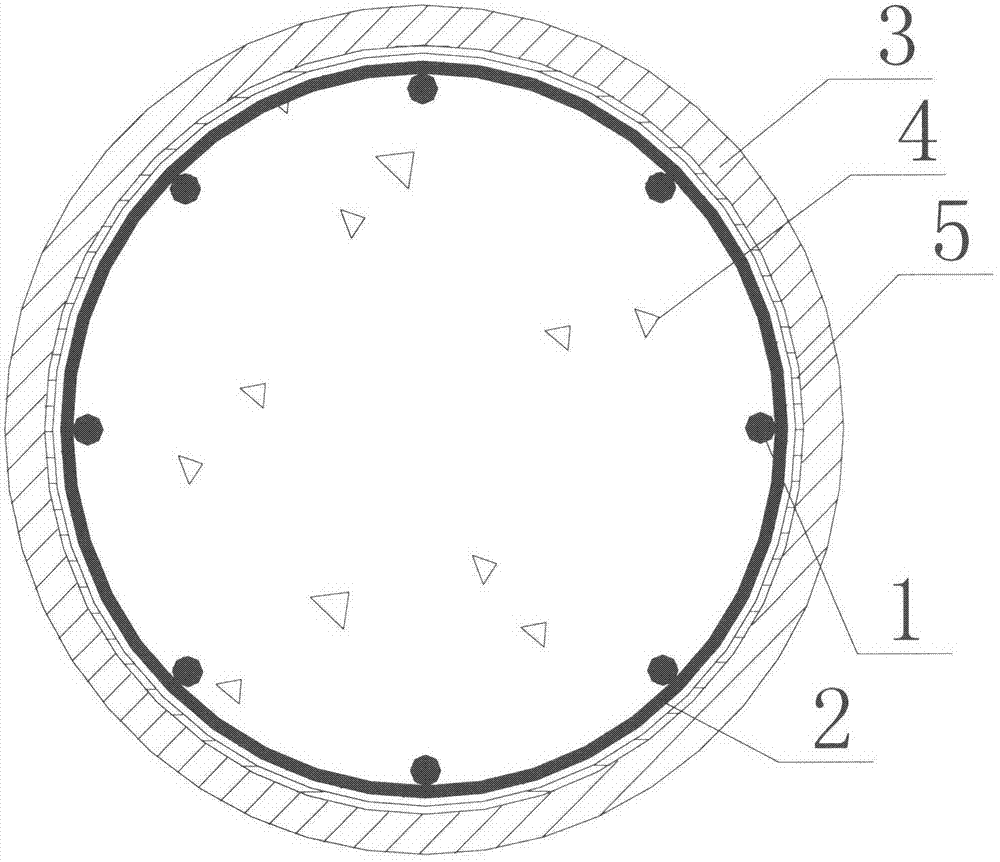

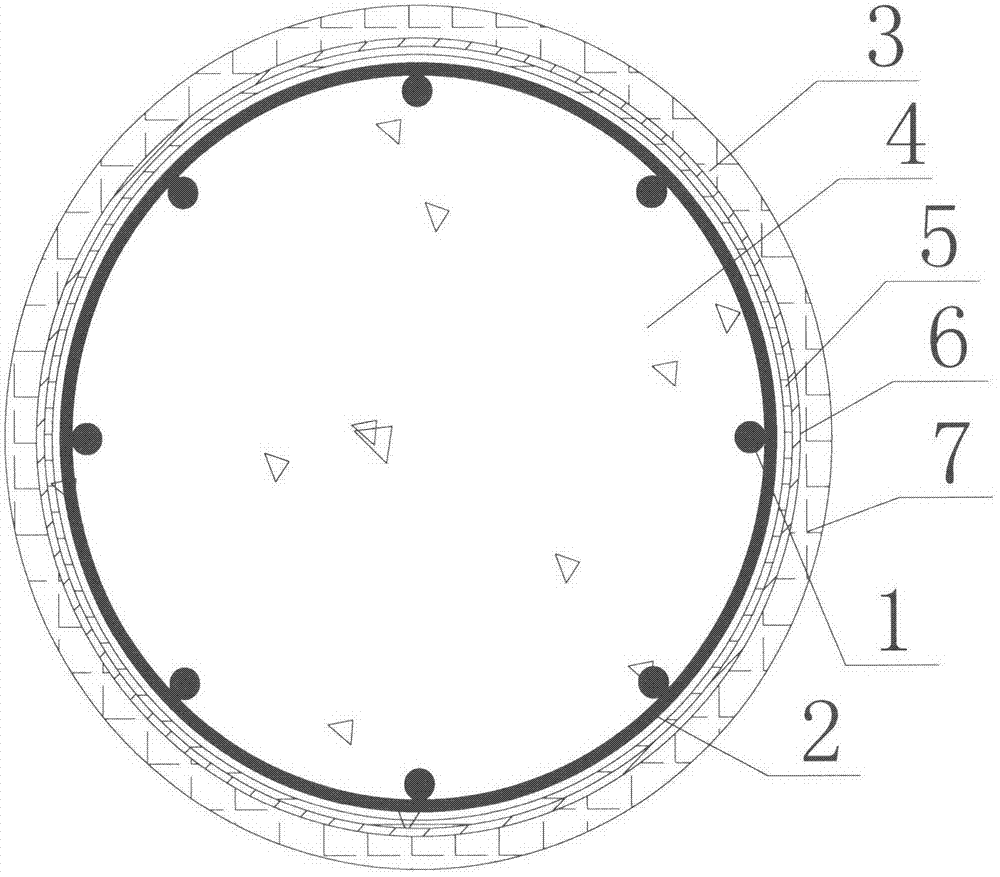

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0023] like Figure 1-Figure 6 As shown, the present invention proposes a constrained concrete-filled steel tube member, which is composed of longitudinal bars 1, stirrups 2, steel tubes 3, core concrete 4, and interface layer 5. It is characterized in that the core concrete 4 is filled inside the steel tube 3, and the steel tube 3 There is an interface layer 5 between the core concrete 4, and one or more decompression notches 6 are provided on the surface of the steel pipe 3. The depth of the notch 6 is greater than or equal to 80% of the thickness of the steel pipe 3 and less than the thickness of the steel pipe 3, the sum of the width c of the decompression notch 6 is not less than 2% of the component length, and the fiber rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com