Novel light composite batten exterior wall and assembling method thereof

A technology of lightweight composite panels and composite slat base walls, applied in walls, building components, buildings, etc., can solve the problems of complex thermal bridge treatment at the flange of light steel keels, environmental pollution of spray-painted walls, and high production costs , to achieve the effect of good promotion and use value, compact structure and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

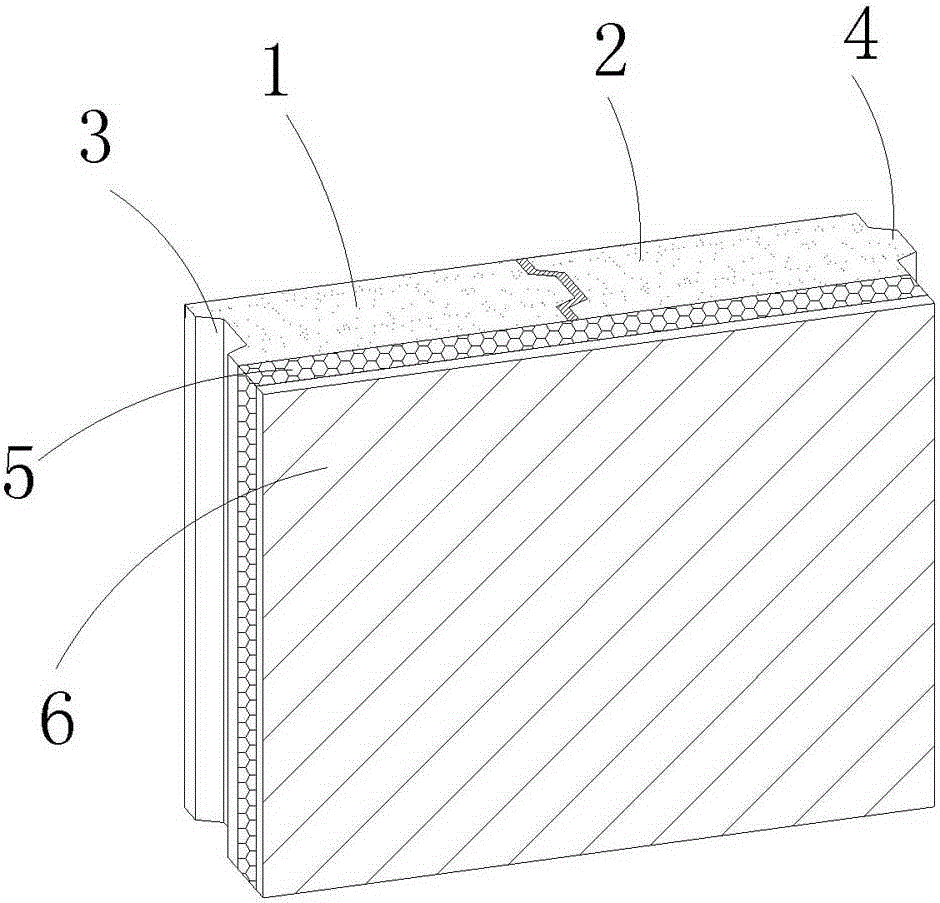

[0031] Embodiment 1: as figure 1 As shown, a new type of lightweight composite panel exterior wall includes a left lightweight composite panel 1 and a right lightweight composite panel 2, and the left ends of the left lightweight composite panel 1 and the right lightweight composite panel 2 are respectively An inner groove 3 is provided, and the right side ends of the left lightweight composite board 1 and the right lightweight composite board 2 are respectively provided with an outer convex groove 4, and the outer convex groove of the left lightweight composite board 1 is connected with the right side. The inner groove in the right lightweight composite board 2 is matched, and the outer wall of the left lightweight composite board 1 and the right lightweight composite board 2 is provided with a light steel keel 5, and the outer wall of the described light steel keel 5 is provided with Decorative composite panels6.

[0032] The outer convex groove 4 and the inner groove 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com