Aerosol-type polishing agent and manufacturing method thereof

A production method, aerosol-type technology, applied in chemical instruments and methods, aqueous dispersants, other chemical processes, etc., can solve the problems of high risk, atmospheric ozone layer destruction, hazardous chemicals, etc., and achieve good atomization effect, Excellent glazing effect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

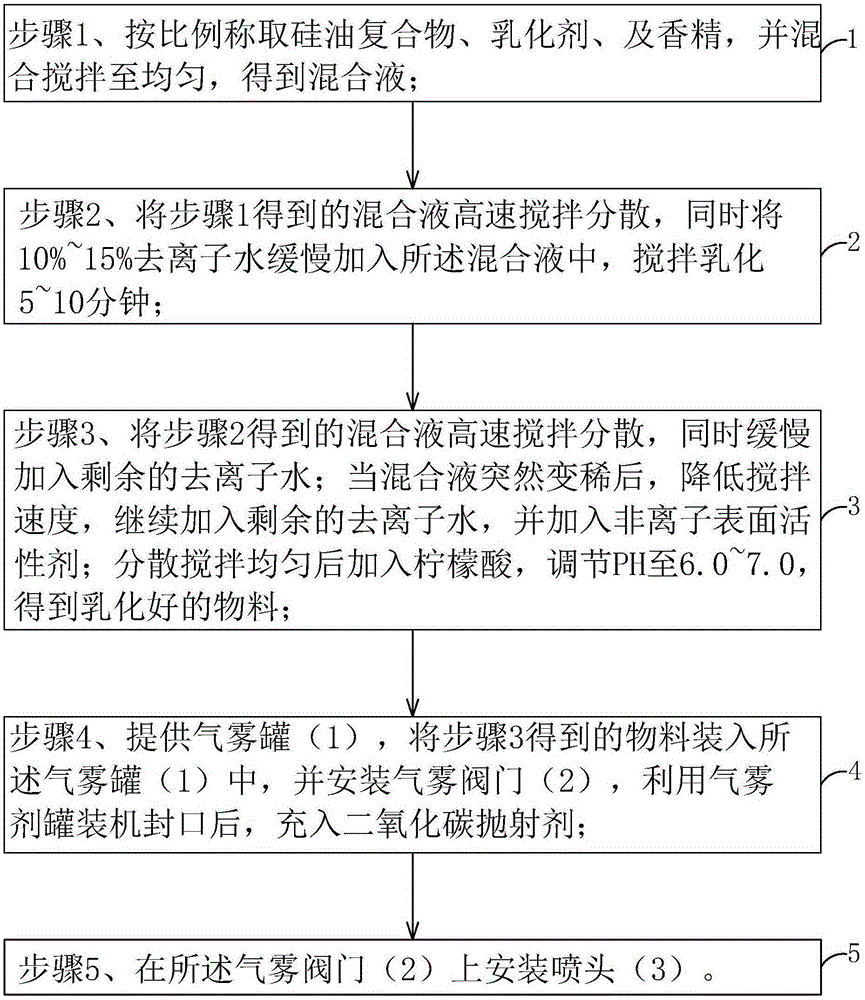

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0035] The present invention firstly provides an aerosol-type glazing agent, which contains components and their weight percentages as follows:

[0036]

[0037] Specifically, the nonionic surfactant is carbon fatty alcohol polyoxyethylene ether, and the carbon fatty alcohol polyoxyethylene ether is a fatty alcohol alkyl chain containing 12 to 14 carbon atoms plus 10 ethylene oxide. The product can be used to improve the stain removal ability of the aerosol polish of the present invention.

[0038] Specifically, the silicone oil compound is a compound of dimethyl silicone oil and amino-modified silicone oil; the amino-modified silicone oil accounts for 10% to 15% by mass of the silicone oil compound; the dimethyl silicone oil And the visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com