A kind of process of preparing adamantane by carbon five dicyclopentadiene

A technology for dicyclopentadiene and adamantane, which is applied in the field of producing adamantane from dicyclopentadiene, can solve the problems of low purity of adamantane, and achieve the advantages of reducing the severity of the reaction, the selectivity, and the degree of polymerization and ring opening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1.0 kg of carbon pentadicyclopentadiene (83% by weight) and 4.0 kg of methylcyclohexane (99.95% by weight) were mixed and then put into a magnetic stirring tank, and then 50 grams of nickel catalyst (by weight) were added to the mixed solution. 95%), replaced with 99.99% nitrogen for three times, passed hydrogen into the magnetic stirring tank, then raised the temperature to 105 °C, maintained the pressure in the tank at 6.0 MPa, stirred for 6 hours, and cooled down to room temperature. The reacted mixture was separated to obtain 800 grams of solid product, which was mixed with 500 grams of aluminum trichloride catalyst and 4.8 grams of ethylaluminum dichloride at 45°C for 6 hours to obtain 340 grams of adamantane product. According to NMR and gas chromatography analysis, the product purity is greater than 99%.

Embodiment 2-10

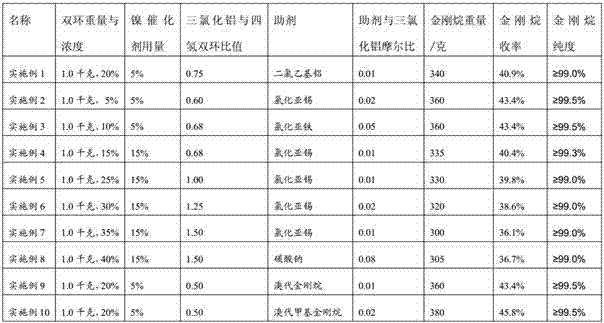

[0022] Carry out hydrogenation to carbon five dicyclopentadiene according to each condition of embodiment 1, just be to regulate the consumption of nickel catalyst, the concentration of dicyclopentadiene, the consumption of aluminum trichloride catalyst and the kind of auxiliary agent and auxiliary agent The ratio with aluminum trichloride is listed in Table 1.

[0023] Table 1

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com