Pectin wastewater decomposition drying treatment technology

A technology of pectin wastewater and treatment process, which is applied in food industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of long drying time, low microbial decomposition efficiency, and fine fruit flesh. The material is perishable and other problems, to achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

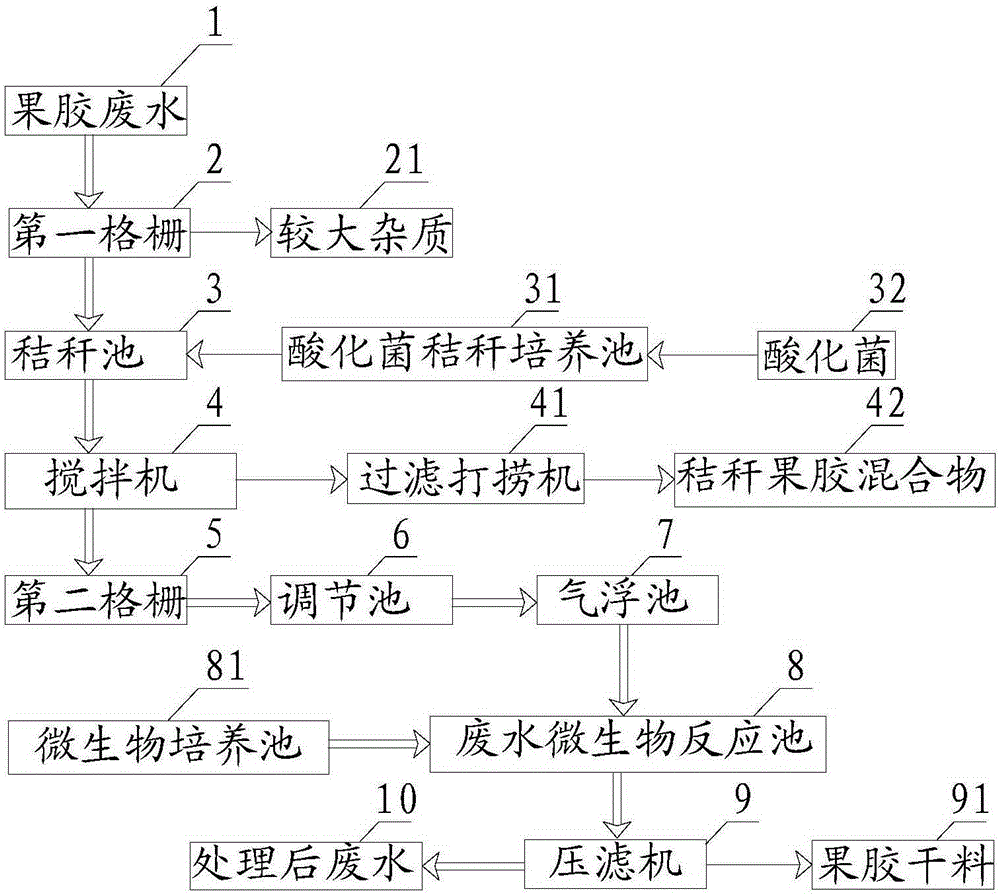

[0018] refer to figure 1 , a kind of pectin wastewater decomposing and drying treatment process of the present invention comprises the following steps:

[0019] Pass the pectin wastewater 1 through the first grid to remove larger impurities 21; the acidifying bacteria straw cultivation pool 31 is equipped with straw, and the acidifying bacteria 32 are cultivated in the straw; the waste water is introduced into the straw pool 3, and the straw is poured into the straw at the same time Pool 3, remove the straw after mixing; make the waste water pass through the second grid 5; introduce the waste water into the air flotation pool 7, and remove a certain amount of pectin in the waste water by aeration and air flotation; adjust the pH value of the waste water 3-8; introduce the waste water into the waste water microbial reaction tank 8, and introduce the mold in the microbial culture tank 81 into the waste water microbial reaction tank 8; use the filter press 9 to filter and compres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com