Technology for preparing sodium fluorosilicate through fluoride-containing wastewater

A technology of sodium fluorosilicate and fluorosilicic acid, which is applied in the field of photoelectric glass deep processing, can solve the problems of high price, limited resources, unfavorable environmental protection, etc., and achieve the effects of reducing production costs, large particles, large economic benefits and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

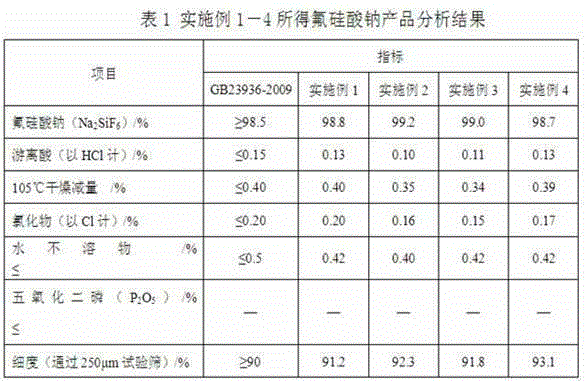

Examples

Embodiment 1

[0019] This embodiment includes the following steps:

[0020] (1) Preparation of fluorosilicic acid: add 1000mL fluorine-containing wastewater to a 2L reactor, wherein the molar concentration of fluorine in the fluoride-containing wastewater is 4.983mol / L, and then add silica with a mass fraction of 72% to the fluoride-containing wastewater 129.41g of silicon slag, the molar ratio of fluorine in the fluorine-containing wastewater to silicon in the silicon slag is controlled to be 3.2:1, the reaction temperature is controlled at 10°C, the stirring speed is 350r / min, and the reaction time is 15min. After the reaction is completed, it is filtered to obtain Fluorosilicic acid solution;

[0021] (2) Preparation of sodium fluorosilicate: Add 497 mL of sodium chloride solution with a mass concentration of 20% to the fluorosilicate solution obtained in step (1), and control the molar ratio of sodium chloride and fluorosilicate in the solution to 1.7: 1. Control the reaction temperatu...

Embodiment 2

[0024] This embodiment includes the following steps:

[0025] (1) Preparation of fluorosilicic acid: Add 1000mL fluorine-containing wastewater to a 2L reactor, wherein the molar concentration of fluorine in the fluoride-containing wastewater is 4.983mol / L, and then add silica with a mass fraction of 73% to the fluoride-containing wastewater 116.71g of silicon slag, the molar ratio of fluorine in the fluorine-containing wastewater to silicon in the silicon slag is controlled to be 3.5:1, the reaction temperature is controlled at 20°C, the stirring speed is 380r / min, and the reaction time is 20min. After the reaction is completed, it is filtered to obtain Fluorosilicic acid solution;

[0026] (2) Preparation of sodium fluorosilicate: Add 446mL of sodium chloride solution with a mass concentration of 25% to the fluorosilicate solution obtained in step (1), and control the molar ratio of sodium chloride and fluorosilicate in the solution to 1.9:1 , the reaction temperature is con...

Embodiment 3

[0029] This embodiment includes the following steps:

[0030] (1) Preparation of fluorosilicic acid: Add 1000mL fluorine-containing wastewater to a 2L reactor, wherein the molar concentration of fluorine in the fluoride-containing wastewater is 4.983mol / L, and then add silica with a mass fraction of 73% to the fluoride-containing wastewater 110.40g of silicon slag, the elemental molar ratio of fluorine in the fluorine-containing wastewater to silicon in the silicon slag is controlled to be 3.7:1, the reaction temperature is controlled at 25°C, the stirring speed is 410r / min, and the reaction time is 30min. After the reaction is completed, it is filtered to obtain Fluorosilicic acid solution;

[0031] (2) Preparation of sodium fluorosilicate: add 491 mL of sodium chloride solution with a mass concentration of 25% to the fluorosilicate solution in step (1), and control the molar ratio of sodium chloride and fluorosilicate in the solution to 2.1:1. The reaction temperature is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com