Material receiving system for automobile

A technology for automobiles and receiving troughs, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of no dust removal, harsh operating environment, and low efficiency, and achieve the effects of reducing material loss, improving operating efficiency, and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

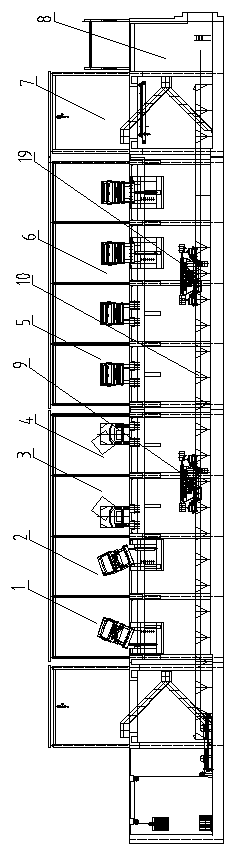

[0021] Such as figure 1 The car material receiving system shown has eight material receiving bins, wherein the material receiving bin 1 is adapted to turning the car to the right, the receiving bin 2 is adapted to the car turning to the left, and the receiving bin 3 is adapted to The dump truck turns to the right to unload, the receiving bin 4 is suitable for the dump truck to turn to the left, the receiving bin 5 is suitable for the dump truck to turn over and unload, and the receiving bin 6 is suitable for the car to turn over and unload material. An overhaul channel 7 and an overhaul storehouse 8 are also provided beside the material bin.

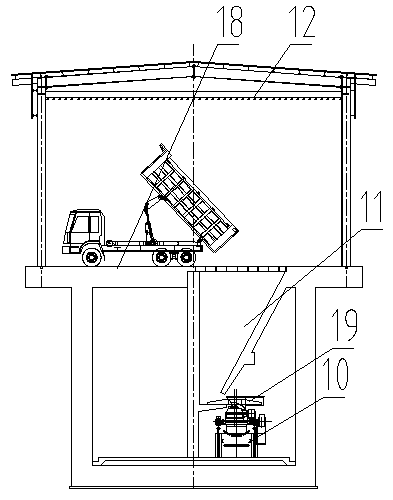

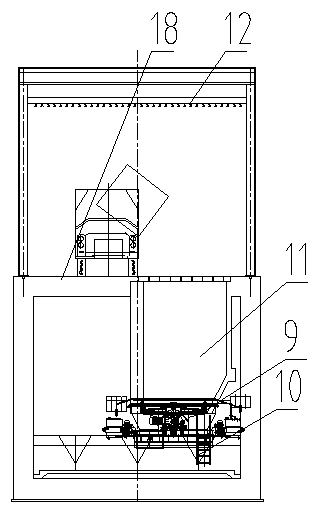

[0022] Such as figure 2 As shown, the receiving bin 5 adapted to the dump truck's backturning and unloading has an unloading platform 18 for the dump truck to stay, and a concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com