Flexo printing machine removable manipulator platform

A technology of manipulators and flexo printing machines, which is applied to general parts of printing machinery, printing machines, rotary printing machines, etc., and can solve problems such as unfavorable market competition, narrow application range of flexo printing machines, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

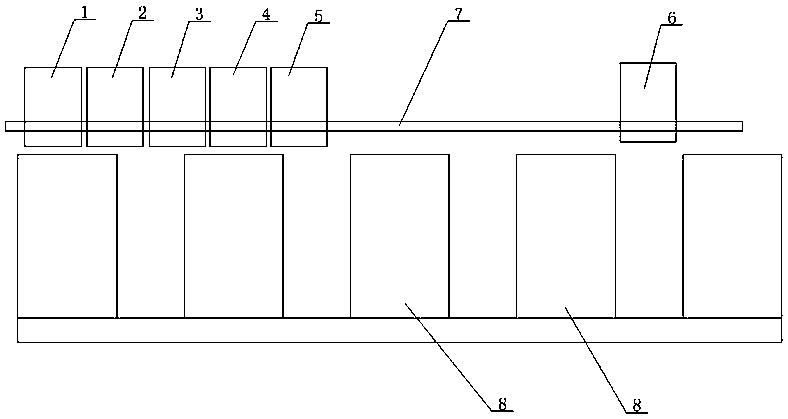

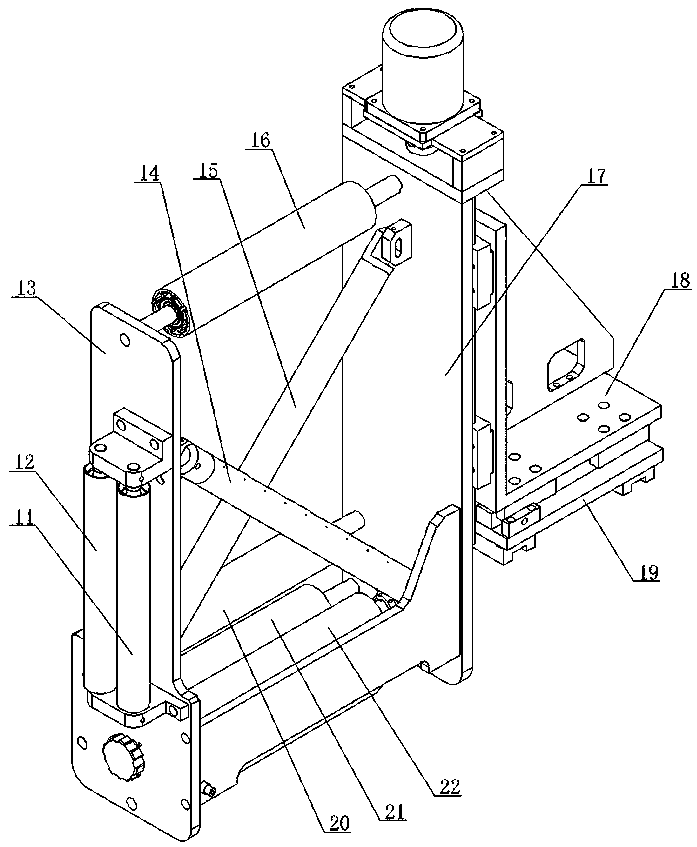

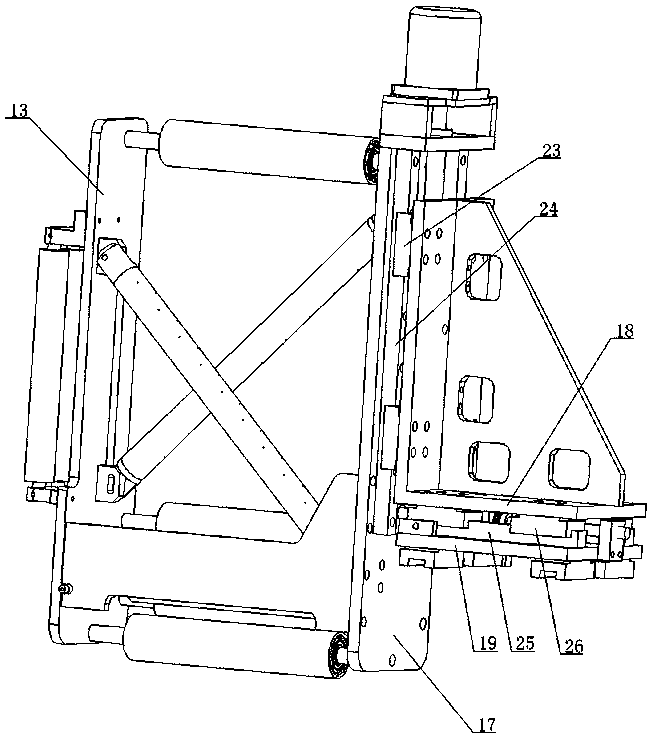

[0014] As shown in the figure, the removable manipulator platform of the flexo printing machine of the present invention consists of a cold stamping manipulator part 1, a laminating manipulator part 2, a varnish manipulator part 3, a die-cutting manipulator part 4, a screen printing manipulator part 5 and a reverse printing manipulator Part 6 is composed of six manipulator parts, and the six manipulator parts are respectively freely movable on the horizontal guide rail 7 above the printing unit 8 of the flexo printing machine along the laying direction of the flexo printing machine. Each manipulator part includes a horizontal slide plate 19 and a longitudinal slide plate 18 and the vertical slide 17, the horizontal slide 19 sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com