Die assembly for manufacturing air-blowing pipe for cable

A technology of air blowing and piping, which is applied to household appliances, other household appliances, applications, etc., can solve the problems of not being able to rent pipeline resources, can only give up, expensive and other problems, and achieve the effect of simple mold structure, stable quality and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

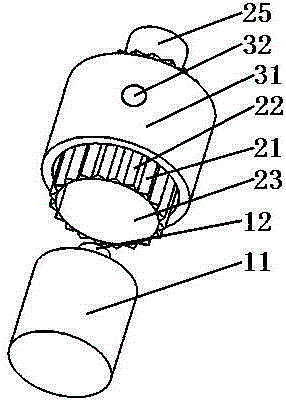

[0045] see Figure 1 to Figure 4 , a mold assembly for manufacturing air blowing pipes for cables, is characterized in that it includes a mold core, a mold cover, and a plunger body; the mold core includes a mold core convex body 22, and the adjacent mold core convex The core groove 21 between the shape body, the core convex body and the core groove are spaced apart to form a columnar body with a hollow core cavity 23, one end of the columnar body is closed, and the outside of the closed end has A mold core connector 25, the inside of the mold core connector has a mold core connection hole 24; the mold cover has a mold cover body 31, the inside of the mold cover body is a hollow mold cover cavity 4, and the mold cover body has a hole through the mold cover cavity. The injection hole 32, the inner wall of the mold cover is cylindrical; the plunger body includes a plunger 11 and a plunger connector 12 at one end of the plunger; The connector is installed on the machine head of ...

Embodiment 2

[0056] see Figure 5 , Image 6 and refer to Figure 1 to Figure 4 , a mold assembly for manufacturing air-blown pipes for cables, which is basically the same as in Example 1, except that the convex body of the mold core and the groove of the mold core are spaced apart from each other and the inner wall of the mold core 26 is continuous below, Below the inner wall of the mold core is a columnar body with a hollow core cavity 23, the wall of the air blowing pipe body of the formed cable air blowing pipe is relatively thick, and the air blowing pipe is stronger, but the material consumption is relatively large The materials of the mold core, mold cover and plunger body are all ceramics; because ceramics have effects such as high temperature resistance, wear resistance, acid and alkali resistance, and easy cleaning, the mold components are quite durable, and the mold components are still durable after 200 times of use. Like new ones, but the mold components made of steel materi...

Embodiment 3

[0058] see Figure 7 to Figure 10 , a mold assembly for manufacturing air-blown pipes for cables, which is basically the same as in Example 2, except that the convex body of the mold core is in the shape of an arc column, and the groove of the mold core is in the shape of an approximate trapezoidal column. The air-blowing pipe formed in this way has a larger guide groove of the air-blowing pipe, can withstand higher pressure during air-blowing, and has a faster air-blowing speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com