Polishing mechanism for corners of glass

A technology for grinding mechanism and glass, applied in machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve problems such as affecting safety, high labor intensity, and production efficiency, and achieve control of noise pollution. , The effect of preventing personal injury and preventing flying debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

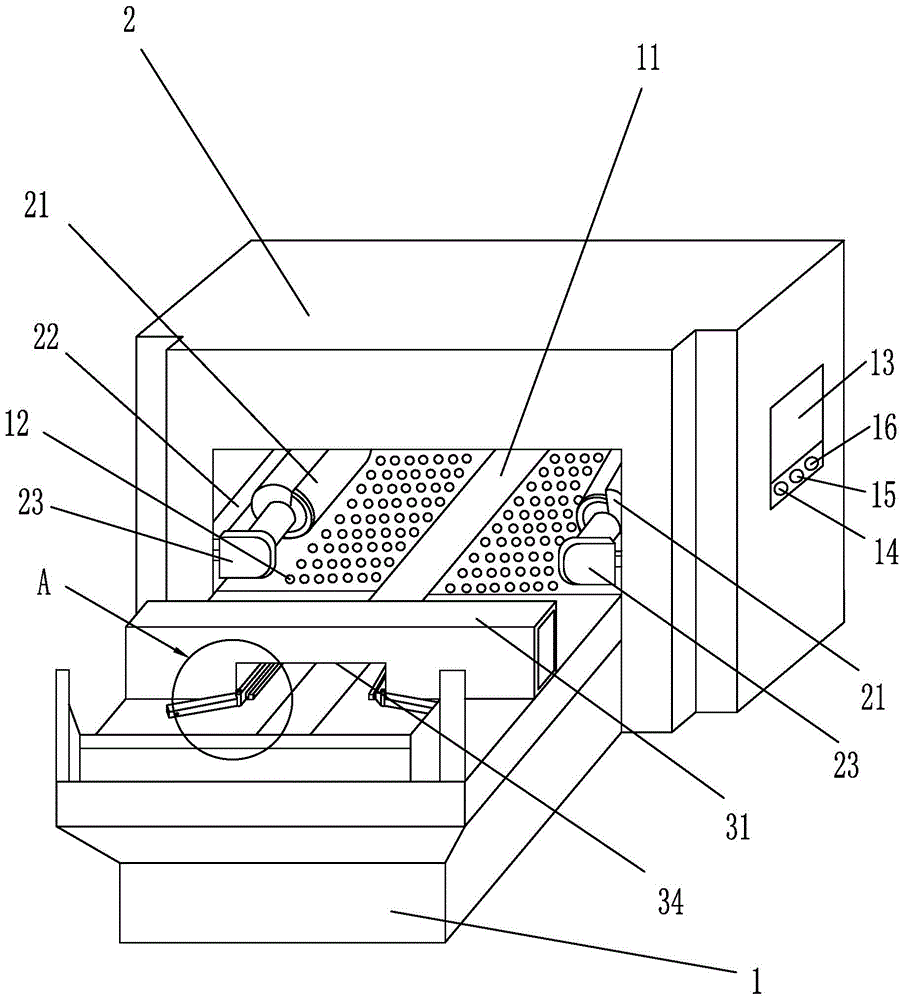

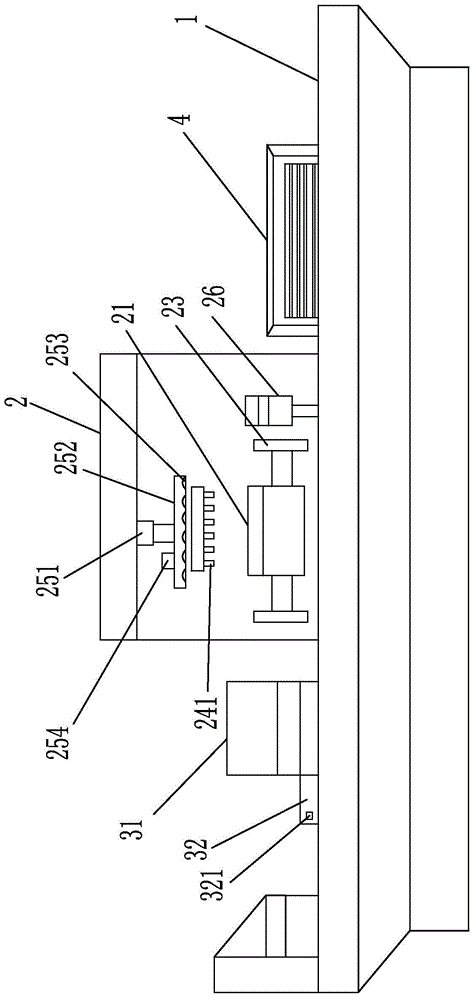

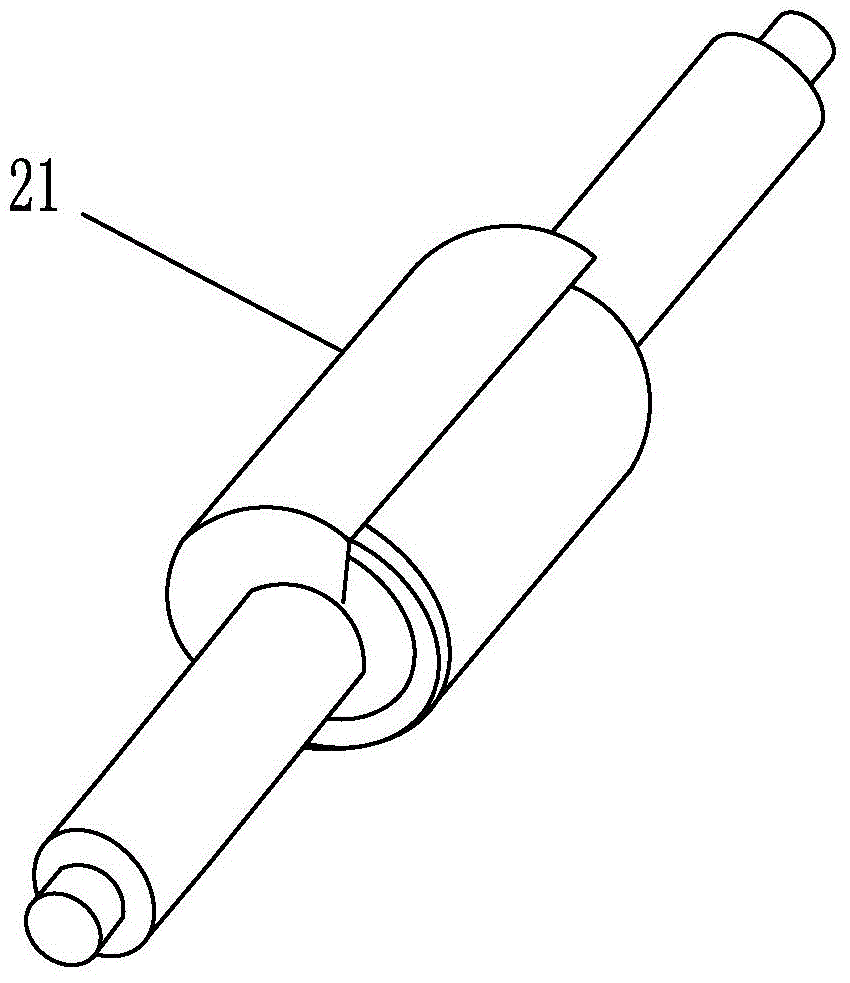

[0030] Such as Figure 1 to Figure 5 As shown, a grinding mechanism for grinding glass corners includes a workbench 1, a grinding chamber 2, an adjustment device, and a drying device 4. The workbench 1 is provided with a grinding chamber 2, and one side of the grinding chamber 2 is provided Adjusting device, the other side of the grinding chamber 2 is provided with a drying device 4, and the workbench 1 is provided with a water drain 12, which is located in the grinding chamber 2, and the cooling water sprayed by the water spray device flows out through the water drain 12 At the same time, the cooling water mixes the glass chips produced during grinding, so that the mixture of glass chips and cooling water is discharged. The polishing chamber 2 is provided with a polishing device. The polishing device includes a polishing wheel 21, an adjusting mechanism 22 and a supporting plate 23. The polishing wheel 21 is fixed between two supporting plates 23. The supporting plate 23 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com