Ice immobilization machining method for metal honeycomb workpiece

A metal honeycomb and processing method technology, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve problems such as limiting clamping reliability and clamping efficiency, difficult to maintain vacuum degree, affecting processing accuracy, etc., to achieve suppression The effects of processing defects, improving cutting accuracy, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

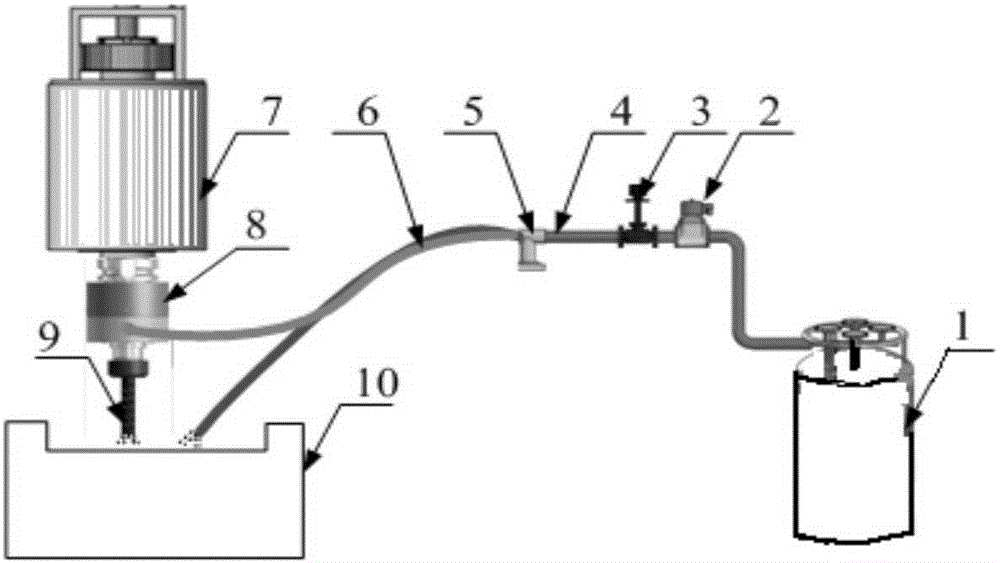

[0018] The metal honeycomb workpiece ice holding method is based on the principle that the radial strength of the metal honeycomb material is low, and the honeycomb hole is filled with low-temperature pure ice to increase the strength of the material.

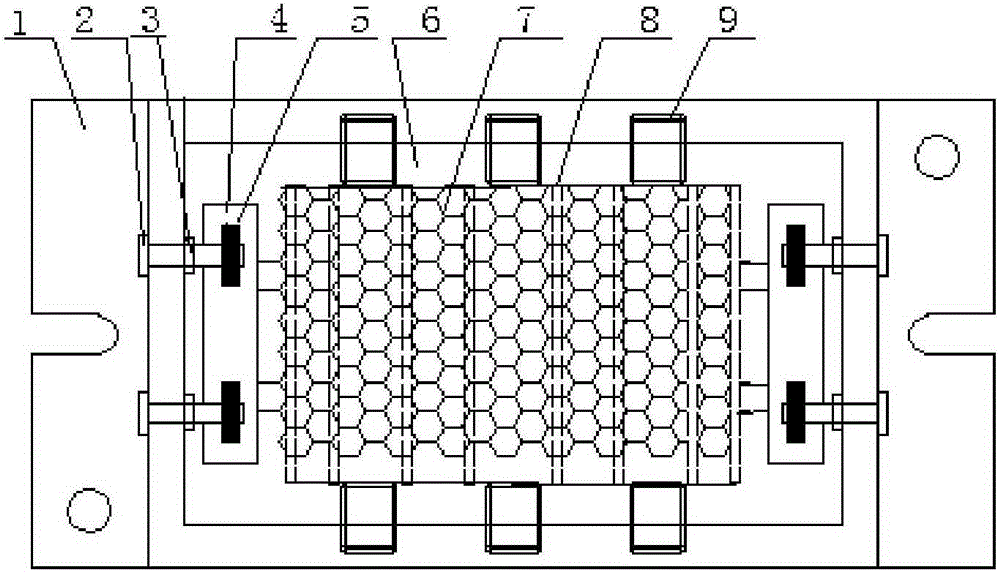

[0019] figure 1 , figure 2 Top view and front view of metal honeycomb ice holding fixture diagram. The installation operation of the metal honeycomb workpiece is as follows: press the support plate 8 into the bottom groove of the hollow clamp body 1; install the ice-fixing bolts 9 into the bolt holes on the front and rear inner walls of the hollow clamp body 1, 6 in total. The metal honeycomb workpiece 7 is placed on the support plate 8, and the adjacent two sides of the metal honeycomb workpiece 7 are connected with the ice-fixing bolts 9 and figure 2 The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com