Positioning clamp and method for machining inner circle face of orthogonal shaft sleeve

A technology of positioning fixtures that are perpendicular to each other. It is used in positioning devices, manufacturing tools, metal processing equipment, etc., and can solve problems such as difficulty in ensuring machining accuracy for drilling machine reaming, and cumbersome operation steps for workpiece clamping, positioning and alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

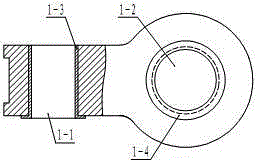

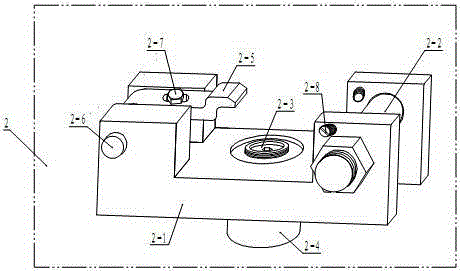

[0044] see image 3 , Figure 4 , Figure 5 , Image 6 , the positioning fixture 2 for processing the inner circular surface of the mutually perpendicular shaft sleeves according to the present invention includes a fixed seat 2-1, a positioning shaft 2-2, an adjustment sleeve 2-3, a clamping seat 2-4, a pressure plate 2-5 and a top wire 2-8; the fixed seat 2-1 is provided with a bottom plate 2-1-1, a first front side wall 2-1-2, a first rear side wall 2-1-3, and a second front side wall 2-1 -4 and the second rear side wall 2-1-5; the base plate 2-1-1 is installed on the lathe chuck, the second front side wall 2-1-4 and the second rear side wall 2-1 The positioning shaft 2-2 of the through structure is installed on the -5, and the positioning shaft 2-2 is two, and one of them is the first shaft sleeve 1-3 inner circle of the joint part, and the second shaft sleeve 1-4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com