An automatic steel bar hook machine controlled by an oil cylinder

A technology for oil cylinders and steel bars, which is applied in the field of automatic steel bar hooking machines controlled by oil cylinders. It can solve the problems of not straightening and cutting steel bars, not being able to meet double-ended hooks, and low degree of automation. It achieves reliable operation, small errors, and high precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

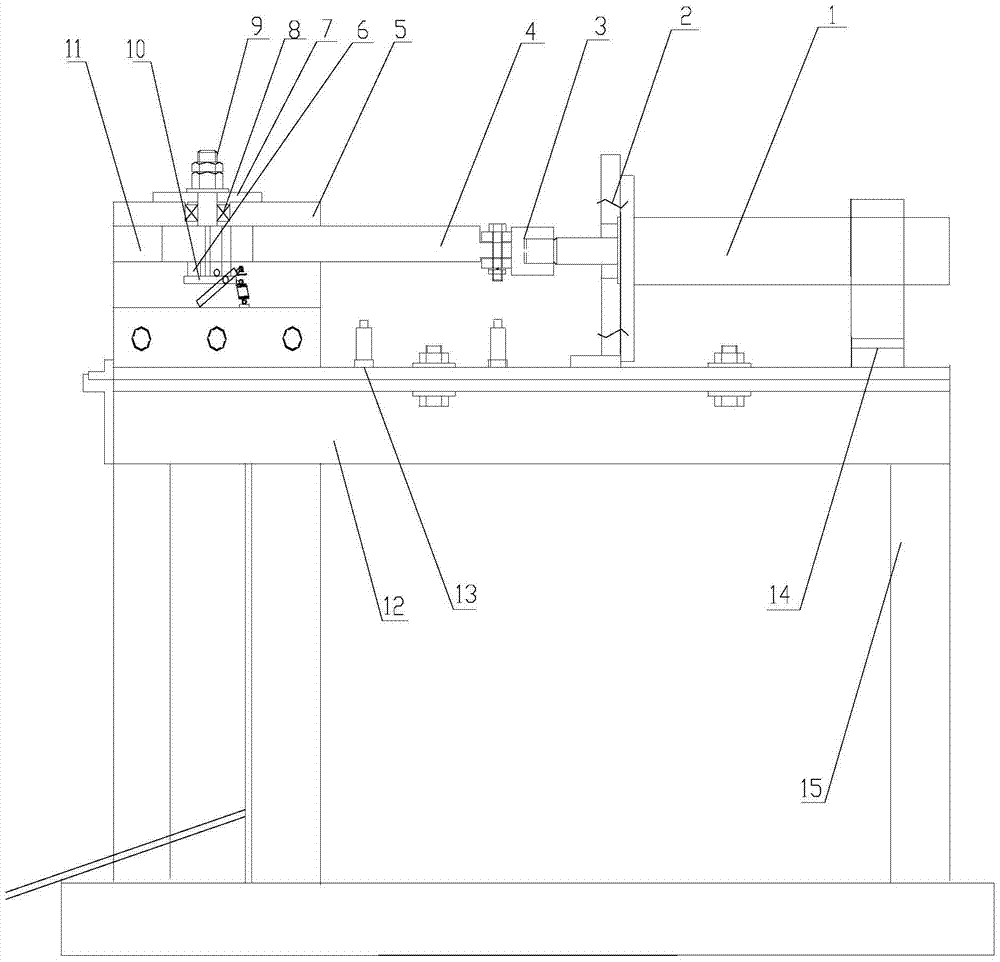

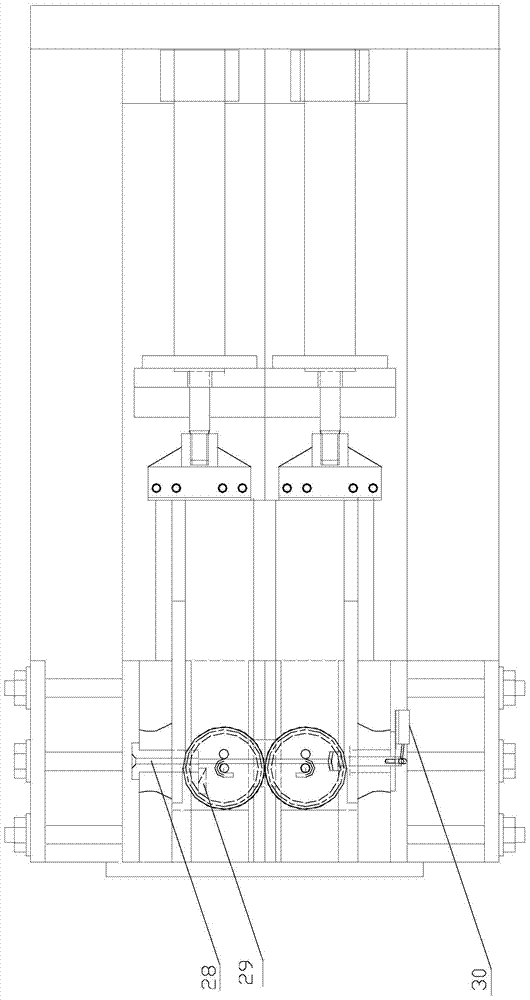

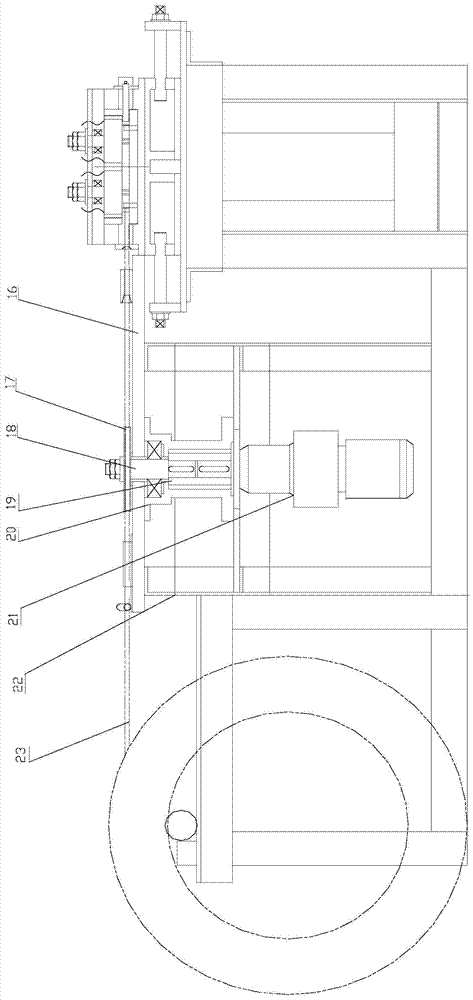

[0013] The invention relates to a steel bar hook machine controlled by an oil cylinder, specifically a hook device that cuts the steel bar according to the required length and bends the steel bar into a single or double hook that meets the requirements by a bar bending mechanism.

[0014] combine figure 1 , figure 2 , image 3 and Figure 4 , The composition of the steel bar hook device includes: oil cylinder 1, oil cylinder flange seat frame 2, cylinder head connector 3, push plate 4, upper cover plate 5, bending bar column 6, bearing gland 7, bearing 8, gear with shaft 9, supporting plate 10, mobile body 11, bed body 12, proximity sensor 13, oil cylinder tailstock 14, main frame 15, feeding machine platen 16, main feeding wheel 17, main wheel shaft 18, coupling sleeve 19, coupling Axle frame 20, geared motor 21, feeding frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com