Device and control method for using electromagnetic attractive force caused by sudden current change to form metal plate

A technology of sudden change of current and sheet metal, applied in the field of electromagnetic forming, can solve the problems of complex process and operation, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

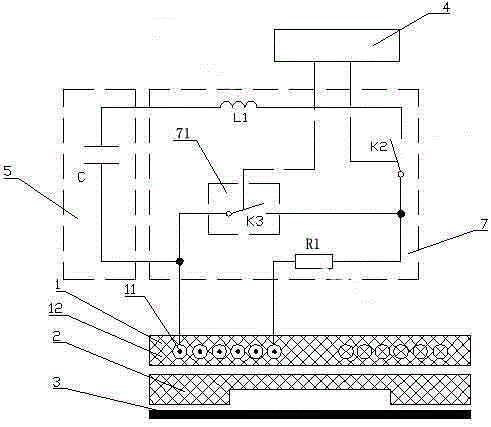

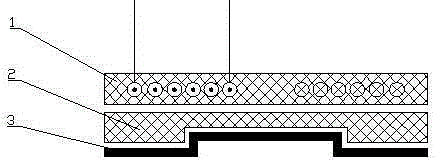

[0049] like figure 1 As shown, the present embodiment provides a device for forming sheet metal by electromagnetic attraction induced by a sudden change in current, including an execution part and a power supply system; the execution part includes a working coil 1, a mold 2, and a sheet metal 3. The mold 2 is set between the working coil 1 and the metal sheet 3, and the working coil 1 and the mold 2 are fixedly connected together as an actuator; the power supply system includes a control system 4, an energy storage system 5, a charging circuit 6 and discharge circuit 7, the charging circuit is connected to both ends of the energy storage system, the two ends of the discharge circuit are also connected to both ends of the energy storage system, the control system 4 and the charging circuit 6, The discharge circuit 7 is electrically connected, and the working coil is electrically connected with the discharge circuit 7 .

[0050] Preferably, the power supply system applies a slo...

Embodiment 2

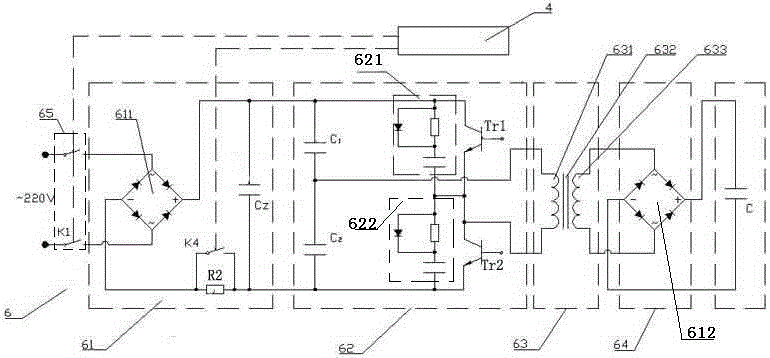

[0069] like Figure 5 As shown, the difference from Embodiment 1 is that the sudden change of current module 71 includes an auxiliary capacitor C3' and a fast switch K3' to replace the fast short-circuit switch K3 in Embodiment 1. After the auxiliary capacitor C3' is connected in series with the fast switch K3', it is connected to the working The coils are connected in parallel. Wherein, the fast short-circuit switch K3' is a thyristor thyristor switch. Therefore, this embodiment provides a control method for a device for forming sheet metal based on the electromagnetic attraction caused by the sudden change of current described above, which mainly includes the following steps:

[0070] Step S1: placing the actuator comprising the working coil and the mold on the metal sheet to be formed;

[0071] Step S2: The control system controls the charging switch K1 in the charging circuit to be closed, the current limiting switch K4 to be open, the discharge switch K2 in the discharg...

Embodiment 3

[0076] like Figure 6 As shown, the difference from Embodiment 1 is that the sudden change of current module 71 includes a fuse switch K3 ″ to replace the fast short-circuit switch K3 in Embodiment 1, and the fuse switch K3 ″ is connected in series with the working coil. Wherein, the fuse switch K3 "includes a fuse for disconnection. Therefore, this embodiment provides a control method based on the above-mentioned sudden change in current that triggers electromagnetic attraction to form a sheet metal device, mainly including the following steps :

[0077] Step S1: placing the actuator comprising the working coil and the mold on the metal sheet to be formed;

[0078] Step S2: The control system controls the charging switch K1 in the charging circuit to be closed, the current limiting switch K4 to be open, the discharge switch K2 in the discharge circuit to be open, and the fuse switch K3" to be closed, and the external power frequency AC input current is stabilized , close th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com