Automatic weighing type feeding machine

An automatic weighing and feeding machine technology, applied in the field of farming machinery, can solve the problems of difficult installation, large running resistance, and high installation cost, and achieve the effects of reducing manual workload, scientific supply and adjustment, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

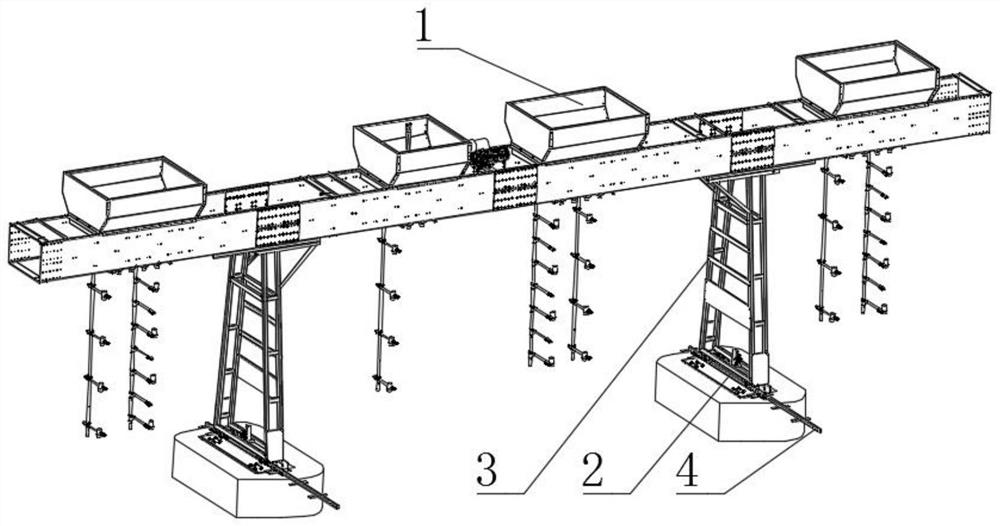

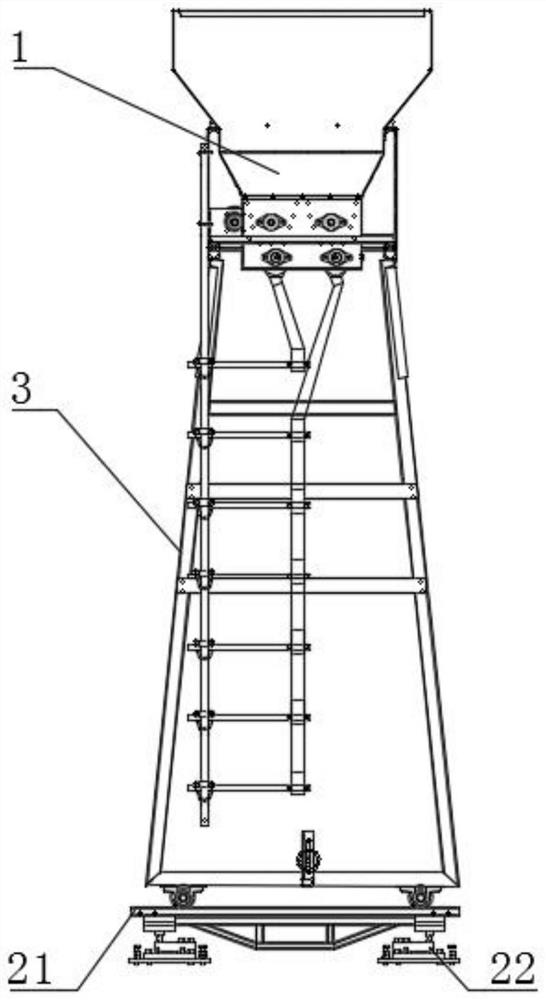

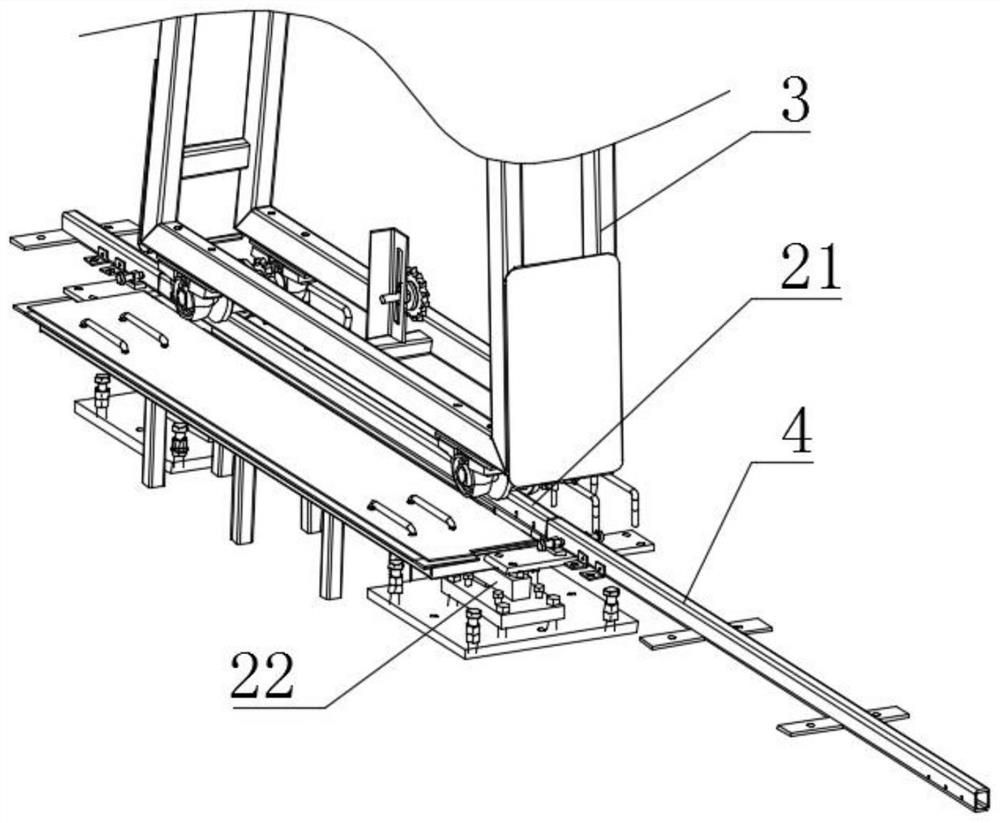

[0033] see Figure 1 to Figure 4 , The invention provides an automatic weighing feeder. The automatic weighing feeder includes: a feeding module 1, a weighing module 2 and a gantry 3, the feeding module 1 is fixedly connected to the gantry 3, the feeding module 1 synchronously transports the feed to different breeding cages, and the gantry 3 is provided with two outriggers, and the weighing module 2 is located under the gantry 3 , and the gantry 3 can slide on the weighing module 2 . The weighing module 2 includes: a load-bearing beam 21 and a pressure sensor 22 with a base. The two ends of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com