Spin Runoff Fountain

A spin-type, run-of-the-river technology, applied in the direction of injection devices, liquid injection devices, etc., can solve problems such as limited range, fountains cannot move up and down, and affect viewing effects, so as to reduce equipment volume and energy consumption and enrich viewing effects , the effect of enriching the viewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

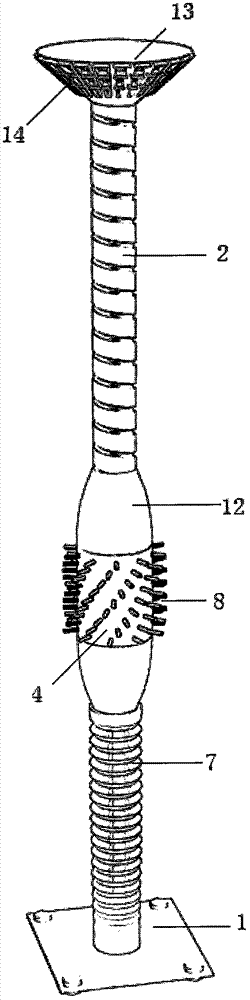

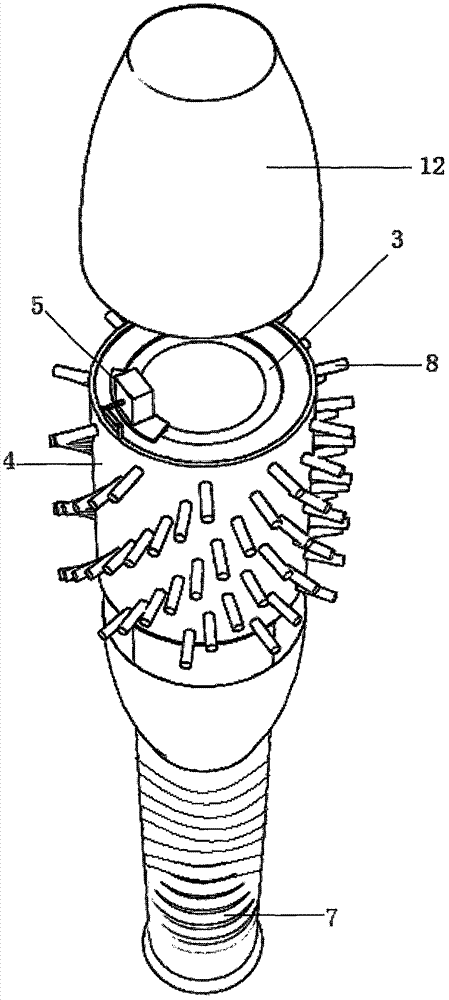

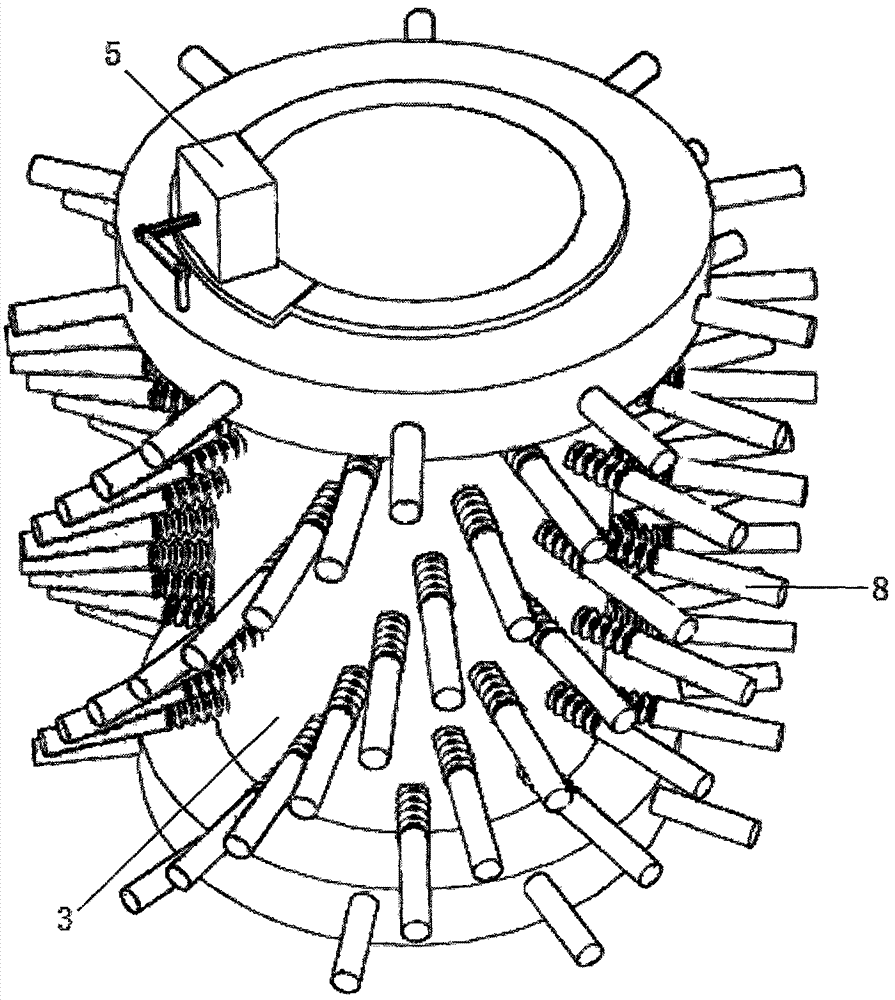

[0018] Such as Figure 1 to Figure 3 As shown, the spin type runoff fountain includes a base 1, a guide rod 2, and the lower end of the guide rod 2 is fixed to the base 1; a spin nozzle mechanism is installed on the guide rod 2; The shunt sleeve 3, the reversing sleeve 4, and the reversing steering gear 5 that are threaded; the shunting sleeve 3 is located inside the reversing sleeve 4 and is rotationally connected with the reversing sleeve 4; the reversing steering gear 5 is installed on the shunting sleeve 3, and the reversing The output end of the steering gear 5 is connected to the reversing sleeve 4; the shunt sleeve 3 is tubular, and the side wall of the shunt sleeve 3 in the circumferential direction is provided with an annular shunt chamber 6; the ring shunt chamber 6 communicates with the water supply pipe 7, and the water supply pipe 7 is a spring The upper end of the water supply pipe 7 is in rotation and sealing fit with the shunt sleeve 3; the outside of the side ...

Embodiment 2

[0021] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the guide rod 2 of the spin-type runoff fountain is tubular; the inner wall of the guide rod 2 is provided with threads in the length direction; the guide rod 2 is provided with a positioning rotor; It includes an external casing 9 threadedly matched with the guide rod and an internal magnetic core rotor 10; the shunt sleeve 3 is slidably matched with the guide rod 2 and magnetically driven with the magnetic core rotor 10; the electric bayonet 11 is fixed on the casing 9; The output end of the pin 11 is clip-fitted with the magnetic core rotor 10 .

Embodiment 1

[0022] In Embodiment 1, the side wall of the guide rod 2 is provided with threads, and the shunt sleeve 3 is directly threaded with the guide rod 2. On the one hand, the rough surface of the guide rod 2 affects the viewing effect, and on the other hand, as long as the shunt sleeve 3 rotates, it will Lifting on the rod 2 cannot be fixed at a certain height to realize rotation alone. In this embodiment, the outer wall of the guide rod 2 is smooth, and the inner wall is provided with threads. The magnetic core rotor 10 inside the positioning rotor cooperates with the magnetic force of the shunt sleeve 3. When the shunt sleeve 3 rotates, the magnetic core rotor 10 can be driven to rotate, and the magnetic core rotor 10 After the electric bayonet pin 11 is relatively fixed to the shell 9, the shell 9 is driven to move and rotate. When the shell 9 rotates, the positioning rotor is raised and lowered along the screw thread, thereby dragging the spin nozzle mechanism to move up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com