Fuzzy predictive control system and method for power supply for electrostatic dust removal

A technology of electrostatic dust removal and fuzzy prediction, which is applied in the field of high-voltage electrostatic dust removal, can solve problems such as difficulty in establishing accurate mathematical models and low cost of controller design, and achieve good adaptability, enhanced self-adaptive ability, and reduced dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

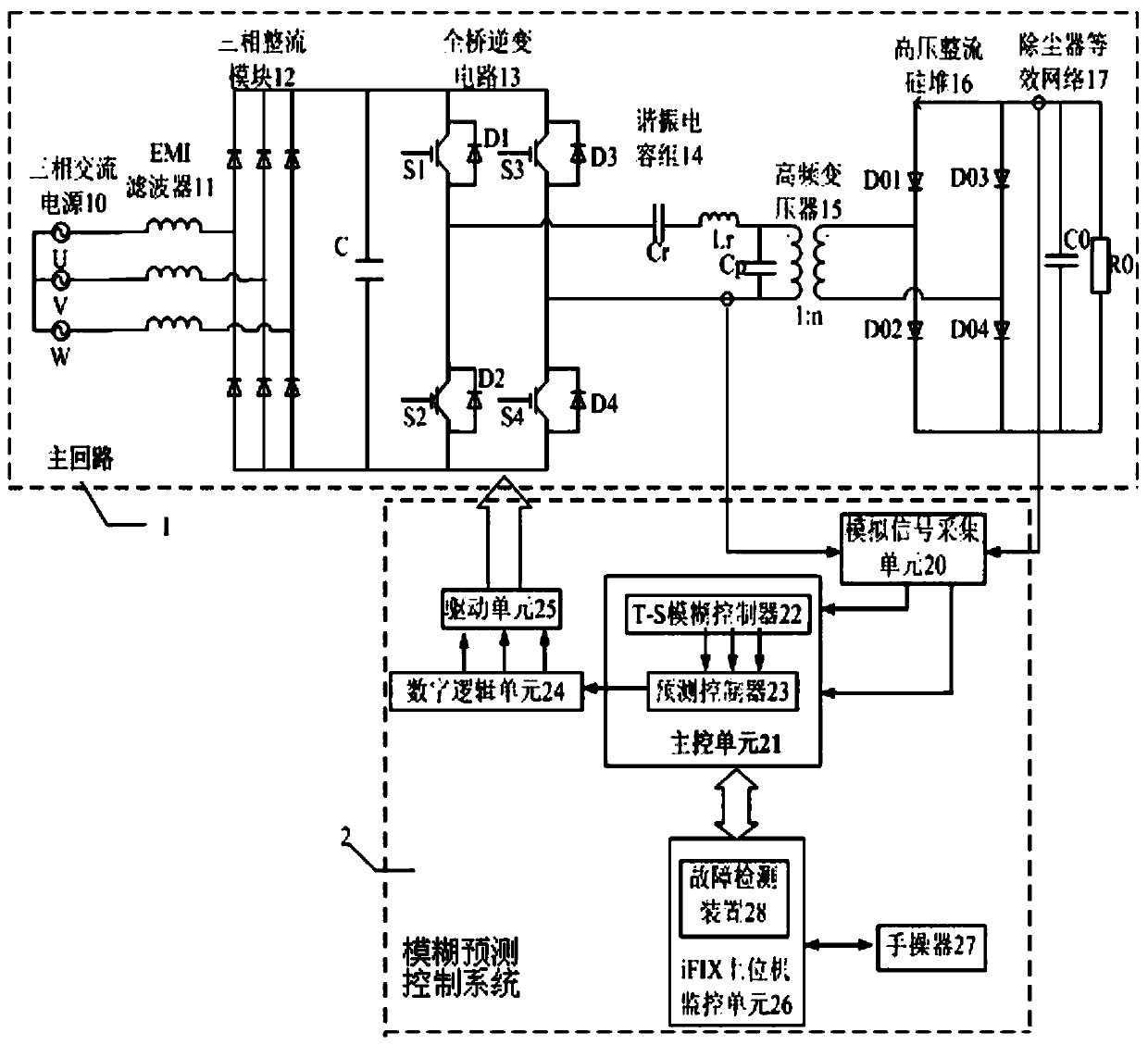

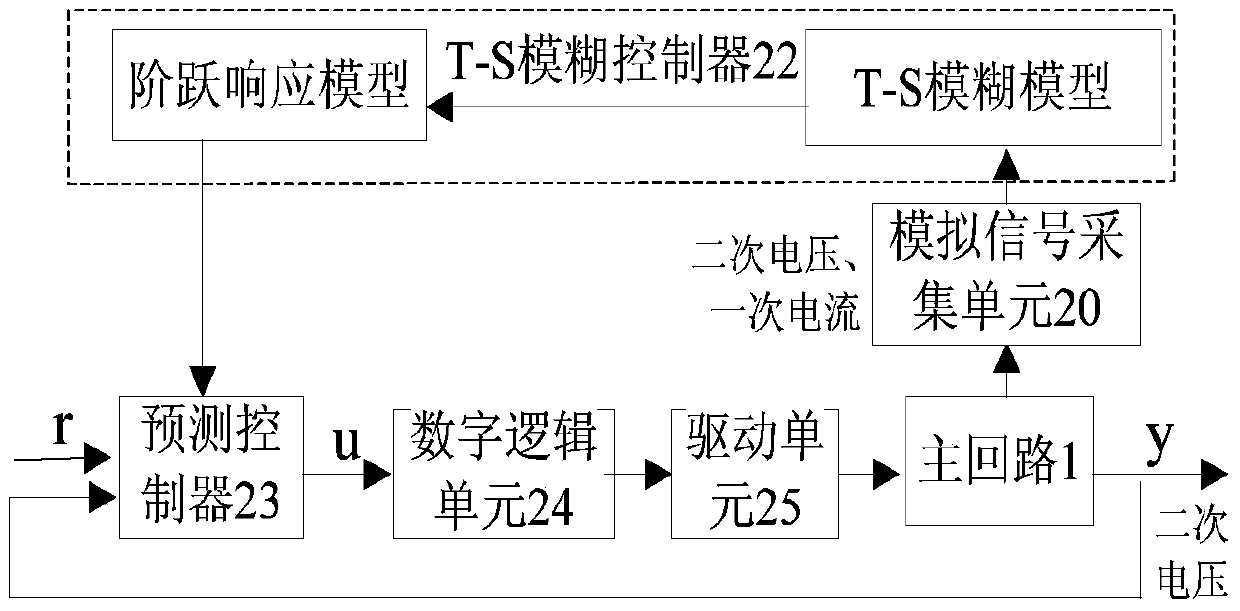

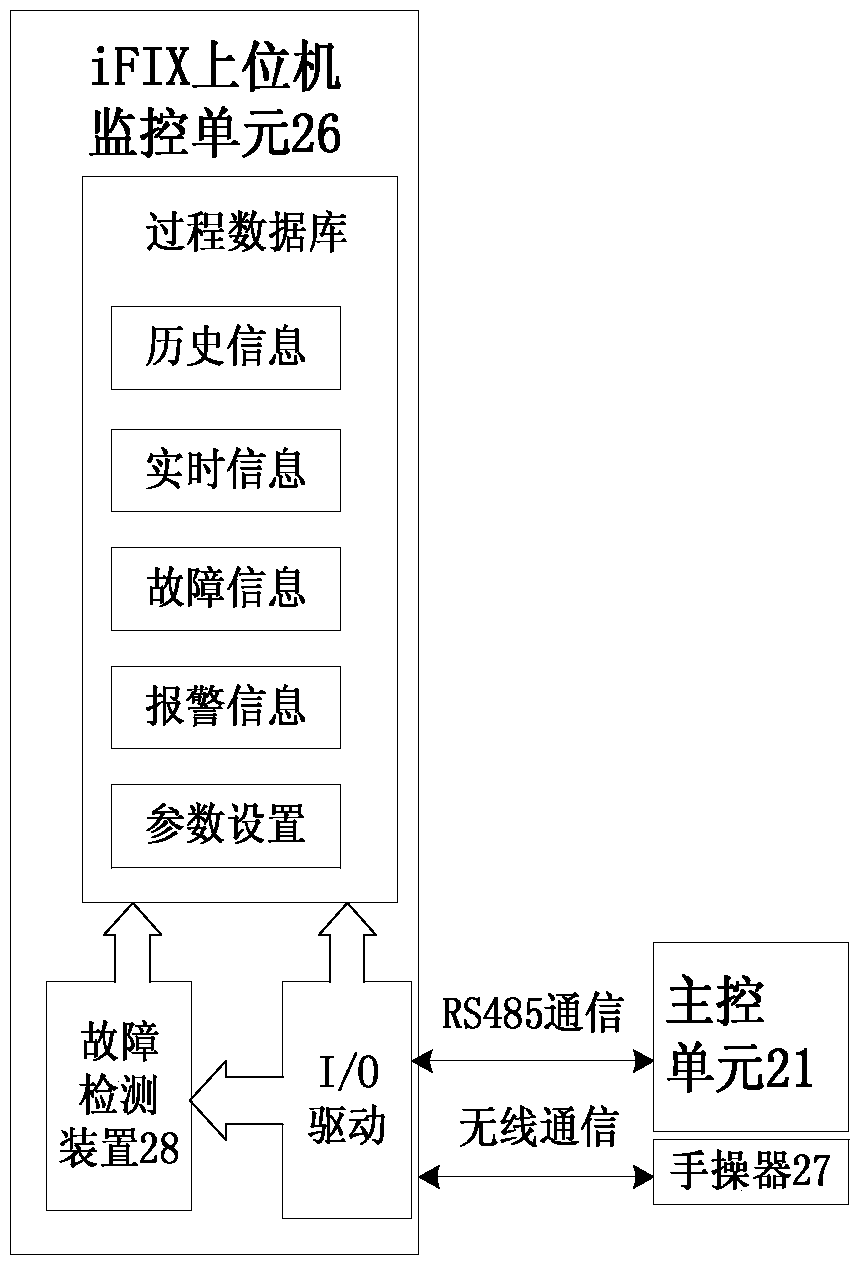

[0023] see figure 1 , the fuzzy prediction control system 2 of the power supply for electrostatic precipitation of the present invention is connected to the main circuit 1 of the power supply system for electrostatic precipitation. The main circuit 1 of the power supply system for electrostatic precipitator includes three-phase AC power supply (U, V, W) 10, EMI filter 11, three-phase rectifier module 12, full-bridge inverter circuit 13, resonant capacitor group 14, high Frequency transformer 15 and high-voltage rectifier silicon stack 16 . The three-phase rectification module 12 adopts a three-phase bridge rectification method. A series-parallel resonant network is formed by the resonant capacitor group 14, the equivalent leakage inductance and distributed capacitance of the high-frequency transformer 15. The high frequency transformer 15 is a high turns ratio high frequency step-up transformer. The output of the high-voltage rectifier silicon stack 16 is connected to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com