High power linear constant current driving LED lamp module

A linear constant current drive, LED lamp module technology, applied in the direction of lamp circuit layout, lighting and heating equipment, point light source, etc., can solve the problem of large no-load power consumption, large change of full-load voltage, resistance-capacitance step-down drive scheme Instability and other issues, to achieve the effect of lossless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

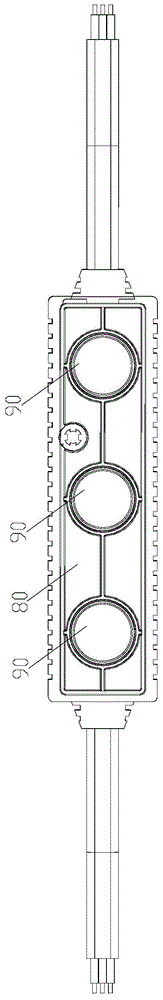

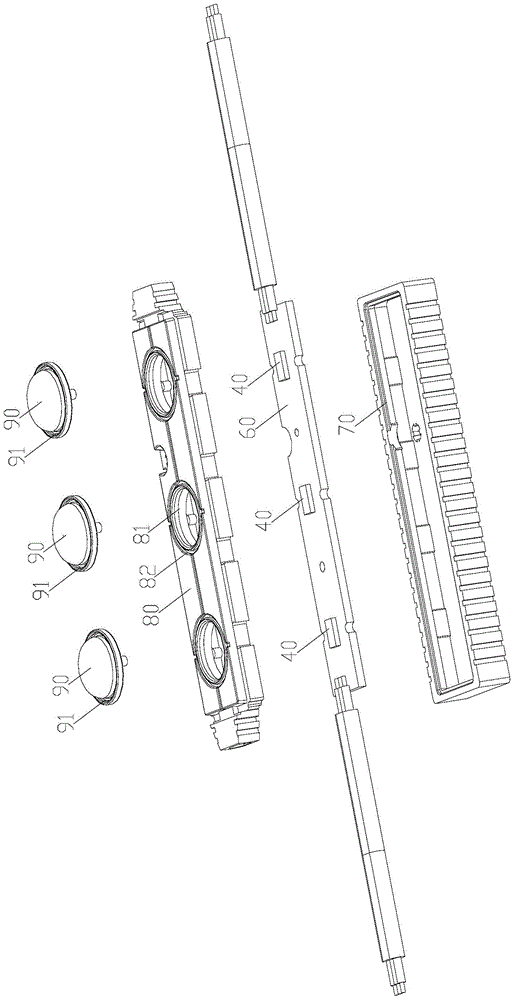

[0013] Such as figure 1 , 2 As shown in and 3, a high-power linear constant current driving LED lamp module provided in this embodiment includes a rectifier bridge 10, and the rectifier bridge 10 has a first diode 11 and a second diode 12 connected end to end. , the third diode 13 and the fourth diode 14, the fourth diode 14 and the first diode 11 have a first node, the first diode 11 and the second There is a second node between the diodes 12, a third node between the second diode 12 and the third diode 13, and the third diode 13 and the fourth diode There is a fourth node between the tubes 14, the third node is connected to the neutral wire terminal, and the fourth node is grounded; the step-down capacitor 21 is located between the live wire terminal and the first node; the linear constant A flow chip 30, the linear constant current chip 30 has a first connection terminal 31, a second connection terminal 32 and a third connection terminal 33, the second connection terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com