DCS automatically checking method

An automatic calibration, server technology, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve the problems of looseness, low utilization rate of calibration results, influence of test operation accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

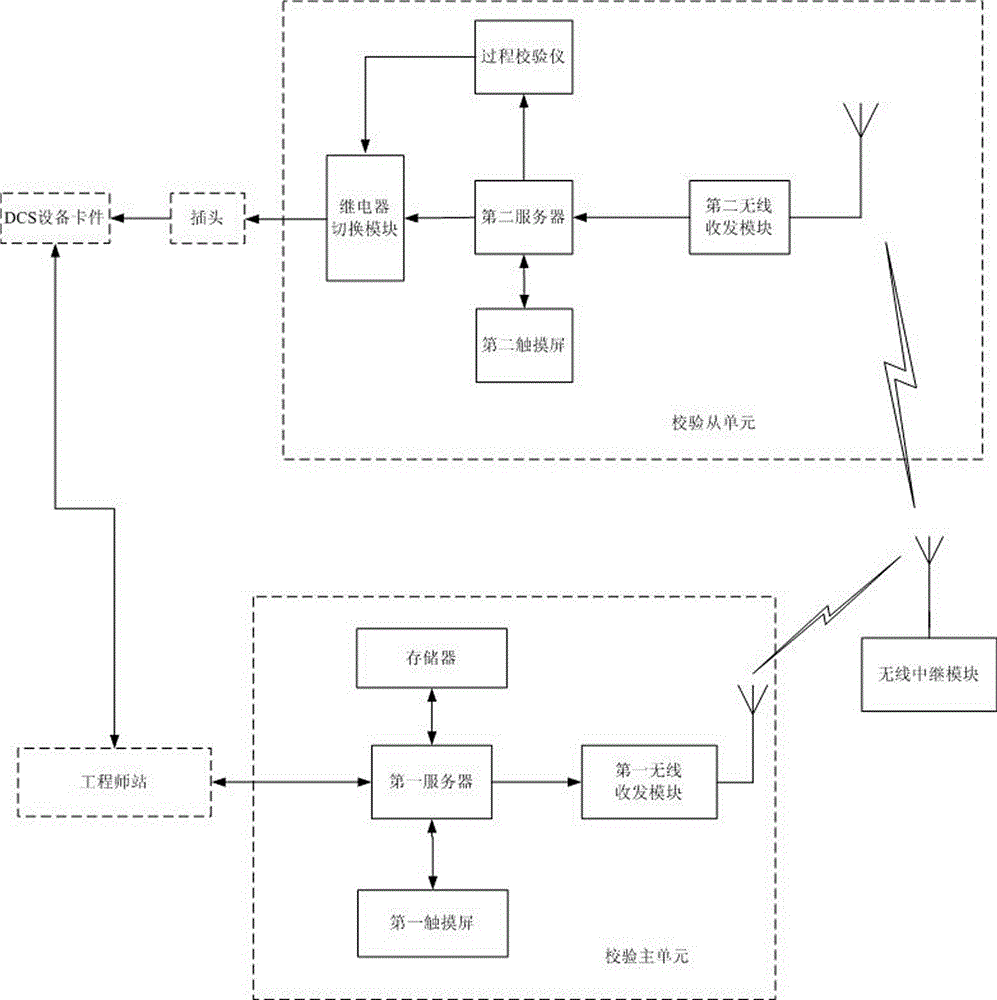

[0011] Depend on figure 1 It can be seen from the illustrated embodiment that it includes a verification master unit, a verification slave unit and a wireless relay module; the verification master unit includes a first server, a first wireless transceiver module, a first touch screen and a memory; The verification slave unit includes a second server, a second wireless transceiver module, a second touch screen, a process calibrator and a relay switching module;

[0012] The first server is bidirectionally connected to the engineer station through the network port; the first touch screen and the memory are respectively bidirectionally connected to the corresponding port of the first server; the input terminal of the first wireless transceiver module is connected to the first server the corresponding output terminal;

[0013] The first wireless transceiver module is wirelessly connected to the wireless relay module; the second wireless transceiver module is wirelessly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com