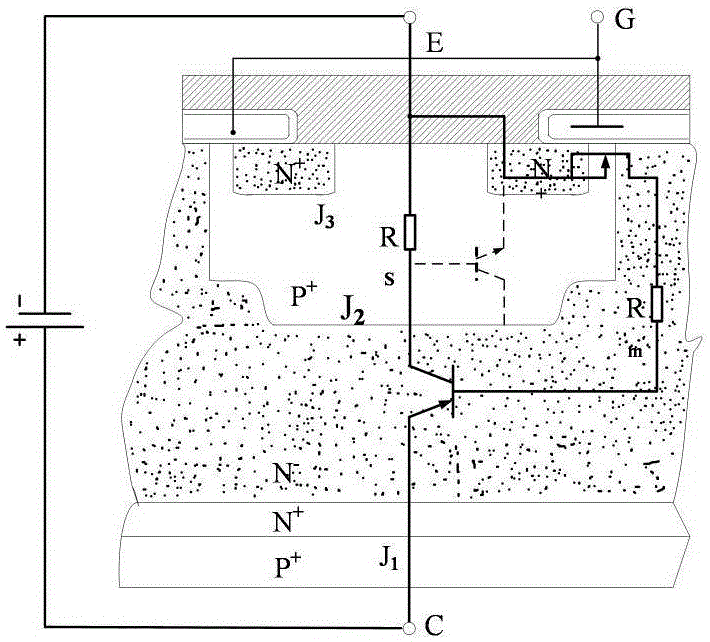

IGBT health state monitoring method based on leakage current of collector electrode

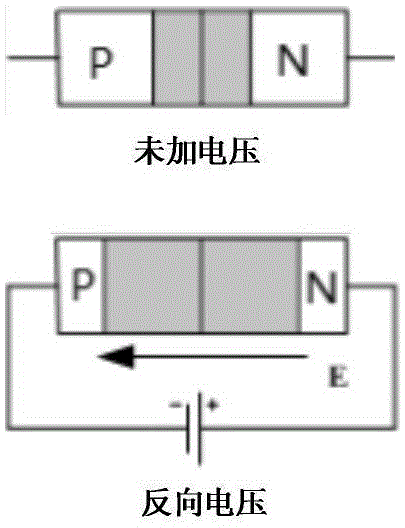

A technology of health status and leakage current, applied in the direction of single semiconductor device testing, etc., can solve problems such as increased potential barrier height, PN short circuit, and increased leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

[0043] The invention provides a method for monitoring the state of health of an IGBT based on collector leakage current, comprising the following steps:

[0044] (1) After installation and debugging, before putting into use, test the collector leakage current of the qualified IGBT device under certain conditions, marked as the initial value I leak(st) ;

[0045] (2) After the IGBT device is put into use, regularly test the collector leakage current of the IGBT device and record the test value I leak ;

[0046] (3) will test the value I leak with initial value I leak(st) For comparison, the collector leakage current is under the same test conditions as step a, and the test value of the collector leakage current is doubled from the initial value, and the device fails. According to the comparison result, it is judged whether the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com